Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayMany generator brands, including Generac, Kohler, Cummins, and Omntec use Modbus protocol for data and alarm information polling.

This article will explain how to poll a generator with Modbus protocol and the best options for implementing a monitoring system for your Modbus generator.

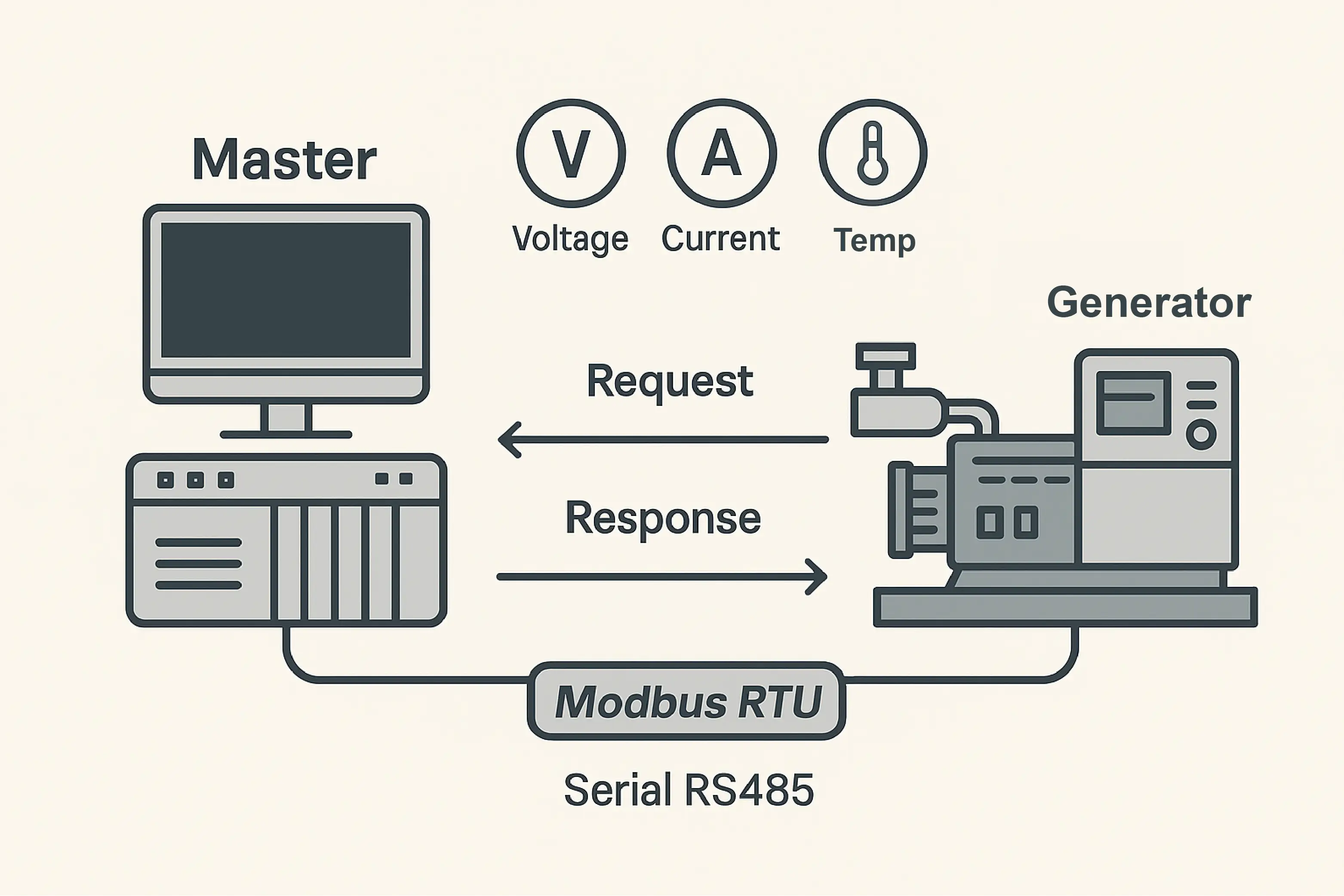

Modbus polling is a communication technique used in Supervisory Control and Data Acquisition (SCADA) systems to exchange data between a master device (such as a computer, PLC, or RTU) and multiple slave devices (sensors, actuators, or other control devices) over a Modbus network. Modbus is a widely used protocol in industrial applications due to its simplicity and effectiveness.

In Modbus polling, the master device initiates communication by sending requests to one or more slave devices to read or write specific data. Here's how the process typically works:

In a Modbus network, there is one master device and one or more Modbus slave devices. The master device is responsible for initiating communication and controlling the data exchange process.

The master device sends a Modbus request to a specific slave device. The request specifies the type of operation (read or write), the address of the data to be accessed, and other relevant parameters.

The addressed slave device processes the request and sends back a response to the master device. This response contains the requested data or an acknowledgment of a successful write operation.

In a read operation, the master device requests data from the slave devices. For example, it might request sensor values, status information, or other process-related data.

In a write operation, the master device sends data to the slave devices. This could include control commands, setpoints, or configuration parameters.

Modbus polling can occur at regular intervals determined by the application requirements. The master device can poll multiple slave devices sequentially or in parallel, depending on the network configuration and the master's capabilities.

Modbus polling involves error checking mechanisms to ensure the integrity of data transmission. If a response from a slave device indicates an error, the master device can take appropriate actions, such as retransmitting the request or notifying an operator.

Modbus polling allows the master device to effectively communicate with various slave devices, enabling real-time monitoring, control, and data acquisition in industrial environments. It's important to configure the polling process correctly, considering factors such as the communication speed, network topology, and the nature of the devices being accessed, to ensure reliable and efficient data exchange within the industrial automation system.

To poll a generator using Modbus, you need a Modbus master device that communicates with the generator's Modbus-compatible slave devices. Here's a general guide on how to poll a generator using Modbus:

Determine which components of the generator are equipped with Modbus communication capabilities. These may include the generator controller, power meters, sensors (temperature, pressure, etc.), and other relevant devices.

Select a Modbus master device such as a Programmable Logic Controller (PLC), Supervisory Control and Data Acquisition (SCADA) system like a Remote Telemetry Unit (RTU) (which, for large-scale infrastructures, can be used in conjunction with an Alarm Master). Ensure that the chosen master device supports Modbus communication.

The benefits of a PLC are that the cost may be low and it it very customizable. But there are also several downsides to using a PLC rather than an RTU. You will have to do all of the programming by yourself , and it will be more difficult to deploy several PLC units to different sites if you have many generators to monitor. A PLC might work best for you if you have the skills to program and configure it yourself, and you only have one or a few generators to monitor.

An RTU, on the other hand, will be much simpler to set up and will be consistent and ready-to-install, which makes them ideal if you have generators at many sites to monitor. They can be less customizable, but collaborating with a company that specializes in creating custom SCADA solutions eliminates this disadvantage.

Configure the Modbus communication parameters on both the master and slave devices. This includes settings such as the communication speed (baud rate), parity, data bits, and stop bits. Ensure that the configuration matches on both ends for successful communication.

If using a PLC or custom software application, create a Modbus polling program. This program will send Modbus requests to the generator's slave devices to read specific registers (data points) or write data as needed.

Determine which data points you want to monitor or control on the generator. This could include parameters like voltage, current, frequency, temperature, fuel level, or any other relevant information.

In your Modbus polling program, implement commands to read data from the identified data points. Modbus commands typically include the function code, starting address, and the number of registers to read. For example, a Modbus RTU read command might look like: "Read Holding Registers (Function Code 03) starting from address 40001."

Define the polling interval based on your application requirements. The polling interval determines how often the master device sends requests to the generator's slave devices. Consider the frequency at which you need real-time data or control updates.

Include error-handling mechanisms in your program to manage communication issues or errors that may occur during the polling process. This ensures the reliability of data exchange between the master and slave devices.

Test the Modbus polling system in a controlled environment before deploying it in the actual generator monitoring setup. Monitor the communication and ensure that the master device receives the expected data from the generator's slave devices.

Once testing is successful, deploy the Modbus polling system in the generator monitoring setup. Continuously monitor the system to ensure reliable and accurate data exchange between the master and slave devices.

With an RTU, you can configure discrete and analog alarms to send alarm data and notifications via email, voice, SMS, a variety of network protocols, or to an alarm master.

DPS Telecom has provided monitoring solutions for many clients who needed to poll their generators using Modbus protocol. We have Modbus modules available to accompany preexisting DPS remote monitoring systems or to include in a new solution for your generator monitoring goals.

Many RTUs on our most recent G6 platform are able to monitor Modbus. These include the NetGuardian 832/864 G6, NetGuardian 480, NetGuardian 432, NetGuardian 216 G6, and even the HVAC G6. Each of these RTUs were created to meet different monitoring needs for infrastructures of different sizes and with different values to monitor.

The NetGuardian 832A G6 is ideal for monitoring medium and large sites, while a NetGuardian 216 G6 may be better suitable for smaller smaller sites. The HVAC Controller G6 is also equipped to poll your Modbus generators. This solution may suit you if you are looking to control and monitor HVAC systems as well.

Our versatile T/Mon Master Station supports a number of devices from other manufacturers. Click here to view an ever-growing list of devices we support with our T/Mon, including:

If you don't see your device listed, don't worry! We are constantly working to support new modules, and even allow users to create their own. We have worked with several clients to create custom device modules for a small development fee. Contact a member of the DPS Sales or Engineering team at 559-454-1600 or sales@dpstele.com to discuss the best solution to poll your Modbus generators.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 18 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...