Download our free SCADA tutorial.

An introduction to SCADA from your own perspective.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayIf you're asking yourself what the Modbus and RS-485 difference (or RS-232) is, let's start by understanding that Modbus is a protocol for Modbus messages.

Modbus Remote Monitoring and Control traditionally uses RS-232 and RS-485 Modbus communication protocols for collecting data from Modbus slaves. Of the two, Modbus using the RS-485 protocol is more common than RS-232 due to its support for multi-drop communication.

These transports are not in any way limited to Modbus, of course. They're found in a wide variety of other applications. Modbus is just one possible protocol that can be sent via dedicated serial connection.

Modbus is a protocol that (traditionally) uses serial communication lines. Modbus over serial connects the master to Modbus slave devices for collecting register and coil information.

Modbus/TCP was introduced for LAN installations but Modbus over traditional serial transmission networks is still found in many industrial applications and building automation systems. A Modbus master can communicate with up to 247 Modbus Remote Telemetry Units (RTUs) or Intelligent Electronic Devices (IEDs). It uses a unique Modbus address assigned to each RTU.

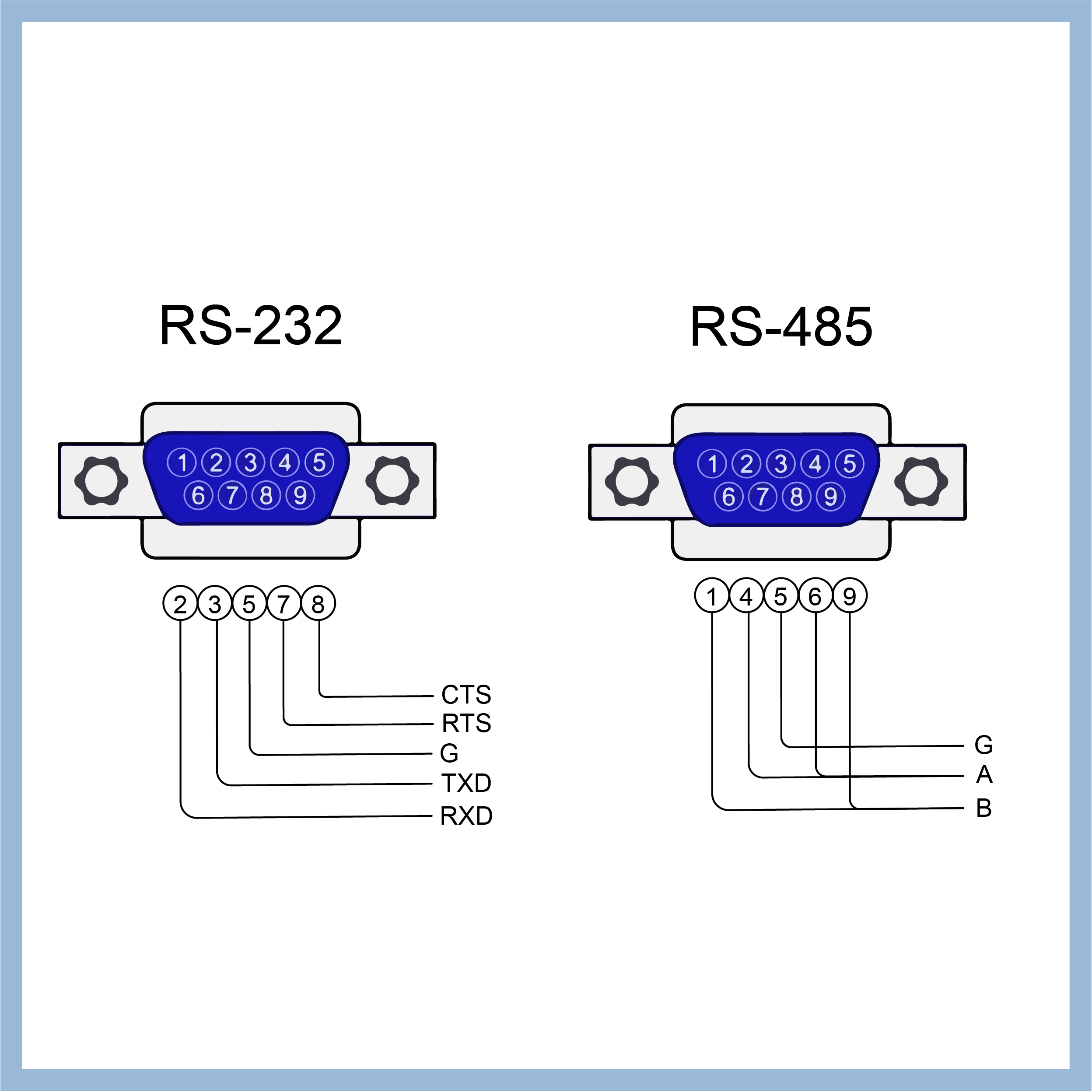

Modbus via RS-232 sends data in the form of a time-series of bits. It is a standard for communication between data terminal and data circuit termination equipment. Full duplex transmission (Tx) and receive (Rx) for data occurs on different circuits when using Modbus RS-232 lines. That means that data is able to flow both ways at the same time.

Modbus RTU RS485 interface is similar, but different, from RS-232. This two-wire, multi-point connection communicates serial data by indicating values by sending different voltages across the two wires. These differences between these voltages are related to one and zero values, which make up the Modbus 485 communications.

By understanding these key advantages, it's clear why RS-485 is preferred in many industrial and commercial settings. Its robust capabilities and versatile applications make it a superior choice for sophisticated communication requirements.

When considering RS-485 as an option over the more commonly known RS-232, there are several drawbacks to keep in mind.

These factors can complicate the decision-making process if ease of use and widespread compatibility are key considerations for your application.

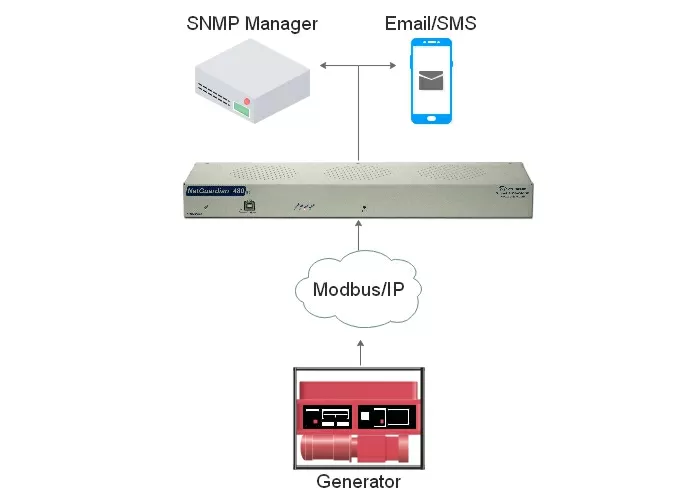

Several DPS clients use Generac, Caterpillar, Kohler, and other generators. They wanted us to interface RS232 / RS485 serial Modbus connection to the generator controller. Also possible is to use DPS' D-Wire propane monitoring sensors to report back to a NetGuardian RTU.

Another client needed remote monitoring and data acquisition for devices they sell to their customers. Their primary business is measuring liquid in tanks (refineries, petrochemical plants, etc.). They have digital inputs (magnetic switches) in their existing management system.

For decades, their customers have put a mechanical device on the tank. The problem is that wiring is expensive to install and maintain. Over the years, they've installed several radio systems, but the radios are typically 900mhz/2.4ghz spread spectrum.

With GSM reporting from a modern monitoring device, the options multiply. We could enable customers to get the data not just in their own office, but also from almost anywhere else in the world.

The tank sensors themselves are analog. There is some intelligence in the enclosure that's an RS-485 or Modbus RS-232 converter, which converts analogs to Modbus. This client came to DPS looking for one small, GSM-capable, and inexpensive Modbus RTU on each tank. They would also need a central collector of some kind (T/Mon).

As you can see, Modbus projects tend to involve a lot of other protocols and equipment.

If you work in telecom, you probably have trouble with any remote RS 485 Modbus equipment. The world has shifted more and more to Ethernet IP, T1, fiber, and other modern transport standards. Dedicated serial lines are tough (and expensive!) to maintain. Wouldn't it be nice to route serial traffic over IP? Then you could keep you old-but-still-functional Modbus gear but abandon the aging serial transport.

One excellent new solution to this problem is a remote Modbus-to-SNMP mediator. This is a fairly simple box that takes in serial Modbus (RS-232 or RS-485) and converts the message to standard SNMP traps. These can be received by your SNMP manager. Because the mediator box is modern, you benefit from recent innovations like SNMPv3.

Unlike earlier versions of SNMP, SNMPv3 is secured with encryption. For many organizations, this is level of security is needed whenever data will be sent via IP.

In order to evaluate the effectiveness of SCADA security solutions, you can use a Modbus traffic generator.

If serial transport isn't your problem, but you still want to integrate Modbus into your SNMP umbrella, you can take a different route. This involves using a Modbus mediating master station to convert inbound Modbus to SNMP. This single stream of usable SNMP traps can be easily sent to your preferred SNMP manager. This master-station solution will generally be much less expensive than installing individual mediation devices at each of your remote sites.

If you work with any kind of legacy equipment, including serial interfacing Modbus device, you need very specialized gear to make it work in today's networks. That's where your choice of manufacturer comes in. Some just sell commodities, and if you need a very unique solution, you're out of luck.

What you need to get a custom Modbus solution is a manufacturer who can take a proven design and adjust it to fit your needs. Look for a company that does its own engineering and manufacturing. They need in-house teams in those areas to be responsive to your special requests. Otherwise, they'll have a really hard time meeting your specs without an insane minimum order.

A company that farms out everything except for their "core competency" simply can't react with the speed that an integrated company can. You need a manufacturer whose core competency is being flexible and giving you exactly the Modbus solution you need.

Do you have specific Modbus requirements? Maybe you need an RTU that can act a Modbus RS485 and RS232 to Modbus converter, or just RS232 to Modbus TCP, or maybe even Modbus TCP to RS232. If that's your case, our custom-designed monitoring solutions can help you.

Related Products:

Related Topics: