Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat Today

South Central Utah Telephone Association began offering telephone service to the rural areas of Southern Utah in 1953. Over the years, as the telecommunications industry and technology advanced, South Central Communications (SCC) has become much more than a telephone company.

Today, SCC is the leading provider of high-speed internet and broadband solutions within every community they serve. Additionally, they provide fiber optic connectivity to local schools and businesses.

John Bair is a Network Engineer at SCC and Chris Covington is a Central Office Technician.

"Everyone likes it a lot better than the old [equipment]."

In 2010, SouthCentral Communications started integrating DPS Telecom equipment into their existing network. Prior to that, they used legacy RTUs.

Because the original equipment was older, it did not have modern functions. "It had no SNMP ability. It was all dry contact, discrete-type of alarm points," said Bair. "They were a little bit fickle. We are phasing them out."

A majority of the equipment they previously used did not function properly. "Especially the dialer. We got rid of that first thing because that was really annoying," said Bair. "The voice was bad, it would break. It would stop working."

"Training made me more aware of some of the analog sensors that we maybe should be using and aren't."

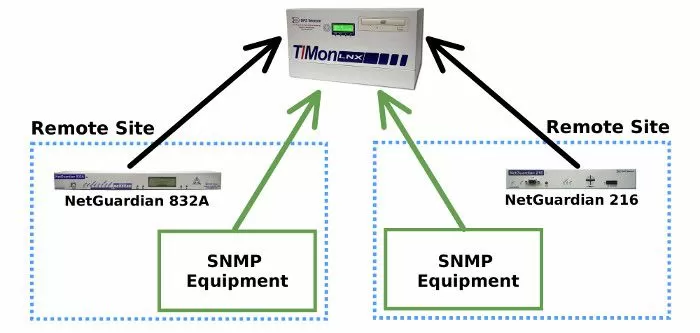

SCC realized that most of their equipment was out of date or no longer supported, so they chose DPS Telecom to upgrade. "Now, we have a T/Mon LNX and two NetGuardian 832s, and a bunch of 216s," said Bair. "We are in the process of getting those installed across our network right now."

While new RTUs provide better visibility for SCC, it is only the start of their overhaul project. "I think the next stage of our implementation will be to make better use of the SNMP manager part of it," said Bair. "Everyone likes it a lot better than the old [equipment]."

To make sure they had a complete understanding of the equipment, SCC sent Bair and Covington to DPS Factory Training. "It was a good blend of theory and hands-on," said Bair. "And we learned some things that we know we need to go back and do. Like some better organization of the alarm points and databasing new equipment."

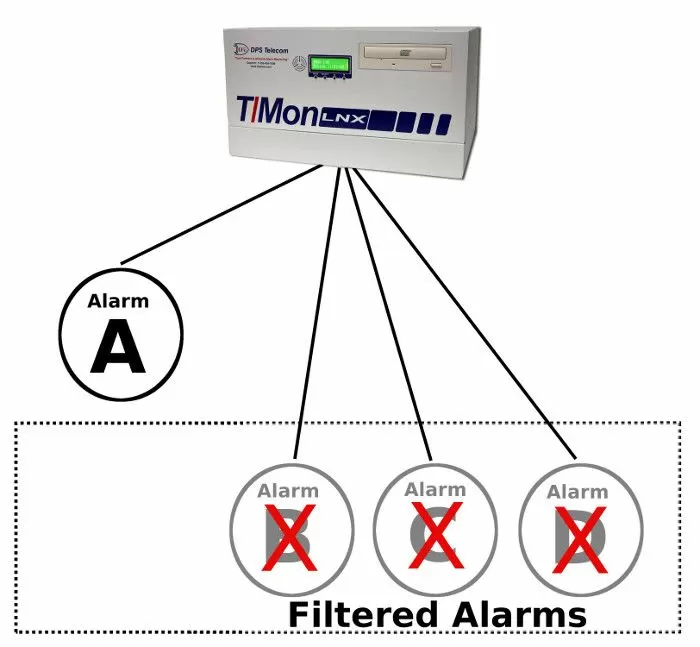

"Training made me more aware of some of the analog sensors that we maybe should be using and aren't," said Bair. "Some of the advanced functionality such as the root alarming and the SNMP, we haven't used those features to its potential yet so that's something we are looking forward to implementing when we get back."

Factory Training helped to highlight all the features that SCC could be used to improve monitoring effectiveness, as well as some features they could potentially use in the future.

"And battery monitoring is something we want to do better. I can see that this could definitely play a role there," said Bair. "Then we also learned some things that are a little bit outside the scope of our company but it also gives us a better awareness of the potential of the equipment so we know what future options might be."