Download our free Monitoring Fundamentals Tutorial.

An introduction to Monitoring Fundamentals strictly from the perspective of telecom network alarm management.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat Today"Windshield time" is all the unproductive time that your technicians spend traveling to and from remote sites during a truck roll. This gets expensive fast.

There's no question about it: truck rolls are expensive. When you are paying your technicians to spend hours of their time sitting in a car, you are greatly raising your costs and wasting their talents. And what if it takes a snowcat or even a helicopter to get to a site?

A good remote monitoring system can prevent hours upon hours of wasted driving time by eliminating unnnecessary truck rolls.

You don't have to put up with windshield time and truck roll expense. Here are 10 leading causes of windshield time - and how to avoid them:

Unexpected outages that require unscheduled repairs at remote sites

Unscheduled repairs create uncontrollable windshield time costs. If you don't know how many truck rolls are going to happen this month, you don't know what your operational expenses really are.

You can bring your outages and your truck rolls under control with proactive network monitoring. Getting visibility of growing problems before they cause outages lets you take care them during regularly scheduled maintenance. Check your event logs for unplanned outages and truck rolls. If you're visiting your sites more often than schedules, it's a sign you need better monitoring.

Making site visits to operate on-site equipment

Many problems can be solved by simply turning a switch, such as starting a backup generator, for example. But if the switch is 20 miles away, that simple solution becomes pretty expensive.

Every device at your sites can and should be remotely operated through your network monitoring equipment. Remote operation enables you to solve more network problems right from the NOC, with no truck roll necessary.

Check your most recent full audit of your remote site equipment and see how much of your equipment isn't controlled from your NOC. Then check that list against your event logs. Determine if any of the uncontrolled equipment caused a truck roll in the last year. This exercise can help you determine if you need to get additional remote controls in place, within your network.

Sending the wrong personnel with the wrong tools and supplies to the remote site

If you don't know what the problem is, how can you be sure you're prepared to correct it? Technicians often travel to remote sites to diagnose the problem, and then have to return to the central office for the correct tools, the correct supplies, or a technician with specialized training.

A quality network alarm monitoring system will give you detailed information about alarm events, ensuring that you'll really know what the problem is and you can send the right person with the right tools to do the job. How much detailed information are you getting from your current monitoring system? Are you confident that, if a repair is required, you can always send a fully prepared technician?

Inability to precisely locate problems

Windshield time can be kept to a minimum if you can pinpoint where problems on your network occur. How often have your technicians had to drive for hours just to locate remote sites and find problems?

You can correct this issue with a network monitoring system that can display a graphic "war-room" representation of your network on a map of your physical locations. Graphic displays can zoom from the national level to region, city, site, rack, device, and alarm point. You'll see exactly where alarms are occurring.

Technicians returning to the central office for remote site keys

If you don't have a keyless entry system for your remote sites, technicians have to come to the central office to obtain remote site keys. If a site needs repairs unexpectedly, technicians may even have to return from the field, just to fetch a key and return to the field again, effectively doubling windshield time.

Installing a keyless entry system not only enhances security but also keeps technicians in the field instead of driving back for the key.

Site visits for turn up and troubleshooting

How much visibility do you have of your remote-site monitoring equipment? Do you need to have someone on site to verify connections and polling between your remote telemetry units and the master?

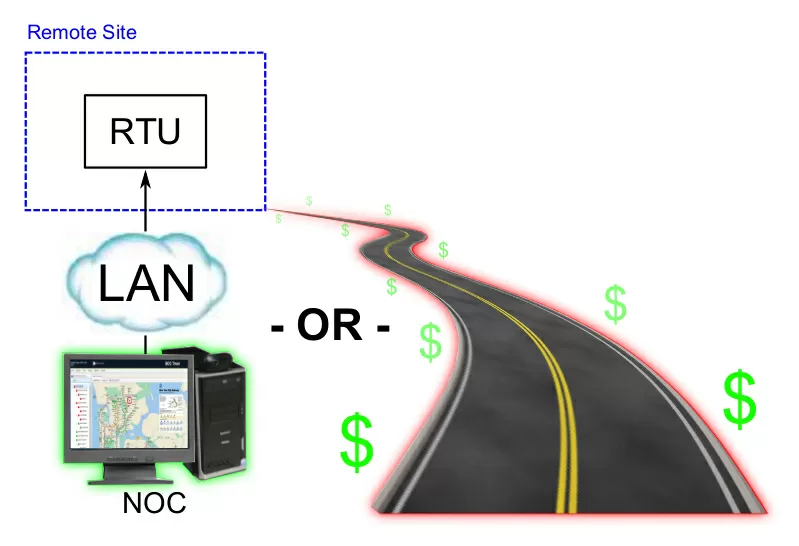

You have a remote monitoring system to decrease windshield time, not create more of it. Make sure your monitoring equipment supports remote access, so you can turn up and troubleshoot your units from the NOC.

Site visits for provisioning remote telemetry units

Site visits are justified if you're physically installing equipment, but not if you're simply sending data. If you have to send a technician to provision a unit, your network can't change and grow without creating more windshield time.

Quality modern network monitoring equipment supports remote provisioning by LAN, so you can administer your database, and make changes whenever necessary, directly from your NOC. Every extra mile is money lost.

Site visits for loading firmware

If you can't update your equipment without physically visiting the site, you have an uncomfortable choice between keeping your monitoring at its current level or incurring more expensive windshield time.

Check your sites for network monitoring equipment that requires a direct serial connection for a firmware download-or even worse, older legacy equipment whose firmware can't be updated except by swapping a circuit board. Quality modern equipment will support firmware updates by LAN.

Site visits for debugging communications problems

Do you have to travel to your remote sites to diagnose and debug communications problems? Do you have to connect special equipment to your transmission lines? If you do, you're creating unnecessary windshield time.

See if your current monitoring system supports a Protocol Analyzer mode. You can and should be able to debug communications traffic right from your alarm monitoring console.

Site visits to operate serial equipment

Can you connect to your serial equipment from the NOC? Or do you have to send a technician to physically hook up a laptop to the equipment? Any data connection that doesn't support LAN is a powerful generator of windshield time.

You can eliminate this problem with LAN-based monitoring equipment that supports reach-through connections to your serial equipment.

At DPS, we receive many urgent quote requests after an earlier "Do Nothing" decision comes back to bite you. You have no reason not to be proactive (and maybe you'll manage to impress your boss).

Call us. Chat with an expert for 10 minutes. We'll email you a detailed quote with a custom application drawing. We'll even include a summary of business benefits you can use to justify your project budget.

Call 1-800-693-0351 now for your quote

(or send us a quick online message instead)