Download our free Monitoring Fundamentals Tutorial.

An introduction to Monitoring Fundamentals strictly from the perspective of telecom network alarm management.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat Today

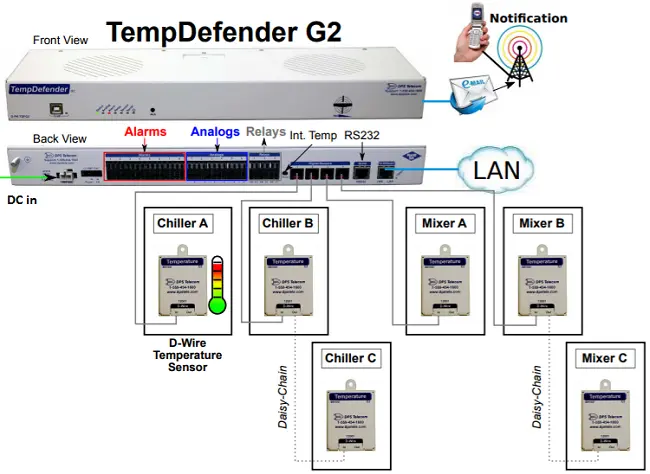

In this example, you have a TempDefender RTU monitoring your 3 bearing chillers and 3 mixers. The sensors are "D-wire" models, which are daisy-chained as bus-powered.

In this example, I'll be showing you how to monitor your bearing chillers and mixers with an RTU. You'll receive alarms if something is out of place.

We'll use the TempDefender G2 RTU in this example. We'll also use D-Wire Temperature sensors. These are nice because you can daisy chain up to 16 of them to gain the most coverage of your chiller. Monitoring the temperature of your chillers and mixers lets you know if something is going wrong.

Depending on how you have your system set up, if a major alarm is crossed, you can latch a control relay. That relay will either cut the power completely (if that is what is necessary) so that a small problem doesn't escalate into something worse.

You want to monitor your chiller for many reasons. We've all come across things that need to stay at a certain temperature. If they go outside this ideal temperature range, it can cause massive financial losses (which can be a career killer).

Monitoring your bearing chiller is important because it's a big investment. You need to be able to receive a notification of something possibly malfunctioning before it get too severe. Knocking out these problems before they grow is a great way to preserve time and money.

With the TempDefender G2 RTU you can monitor your chiller. But you can also daisy chain up to 16 D-Wire sensors to know the exact status of your chiller (ex. Temperature and humidity in multiple places) at all times. You can set thresholds that are customizable to whatever your are trying to keep cool. You can set "minor" and "major" alarms and receive notifications over SMS text or email when a threshold has been crossed.

Pairing other D-Wire sensors like vibration and humidity can be another way to take advantage of the D-wire bus. You could, for example, send an email warning when humidity gets a little too high.

When a major alarm is crossed (humidity MUCH too high) your TempDefender can send a more aggressive SMS text warning to you. It can even automatically activate a control relay to start solving the problem (ex. Activate a dehydrator or open a vent).

Having flexible options to do all of these things saves you the hassle of problems you can avoid with the right visibility.

You should really talk to an expert in remote monitoring to make sure you haven't missed anything. DPS is available at 1-800-693-0351 or sales@dpstele.com to field your questions about bearing chillers, mixers, and other equipment you need to monitor.