Download our free Monitoring Fundamentals Tutorial.

An introduction to Monitoring Fundamentals strictly from the perspective of telecom network alarm management.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayRailroad industry employees working in all sectors know that trade shows are one of the most valuable information resources available when it comes to finding out what products and services are available, how technologies have changed, and researching possible business ventures and investments. For a typical railroad trade show, exhibits from all areas of the railway industry including communications & signals, engineering services, maintenance, mechanical, passenger & transit, structures and track are present. One of the most important take-aways from railroad trade shows is network monitoring. No matter what industry you are involved in, monitoring is a huge factor.

For those involved in Communications & Signals, maintaining a reliable network of conversation and scheduling is of utmost importance in an industry so heavily dependent upon time and shared transit routes. If something were to fail, or technologies not kept up-to-date, faults in the system could lead to catastrophic disasters, or possibly just a delay in services in cases with lesser severity. Either situation though could lead to a loss in profits and service down-time.

The success of the Burlington Northern and Santa Fe Railway Company (BNSF) shows the importance of a reliable network. Through the use of monitoring, BNSF has steadily increased its shipping efficiency by continually modernizing its communications network. "We move information as well as moving trains," said Jim Gaynor, a network analyst in BNSF's technology services department. "The network primarily supports telecommunications for dispatchers. Dispatchers can access signals and switches along the track, and there are also direct telephone-mobile radio connections between the dispatchers and the train crews."

These telecommunications capabilities are essential for managing trains on the move. BNSF dispatchers can track the location of a train throughout its run and schedule runs to maximize the number of trains that can run on the track. This is a form of Positive Train Control, which will be discussed in more detail later.

For individuals involved in Maintenance, knowing what equipment is functioning at full strength and what could potentially fail is a huge aspect of their job. Without proper monitoring solutions of their equipment across many remote sites as well as on trains themselves, technicians are left in the dark to attend to failures and outages after the fact.

It may not seem like a huge area, but HVAC and electrical services in the passenger areas of trains, the refrigeration units, as well as various other systems within the railway industry are always running to ensure customer satisfaction. No one wants to be stuck in a train for hours or even days without proper air-conditioning and filtration or lighting. While produce can remain on trains for weeks, the loss of refrigeration capabilities can lead to expensive loss of goods.

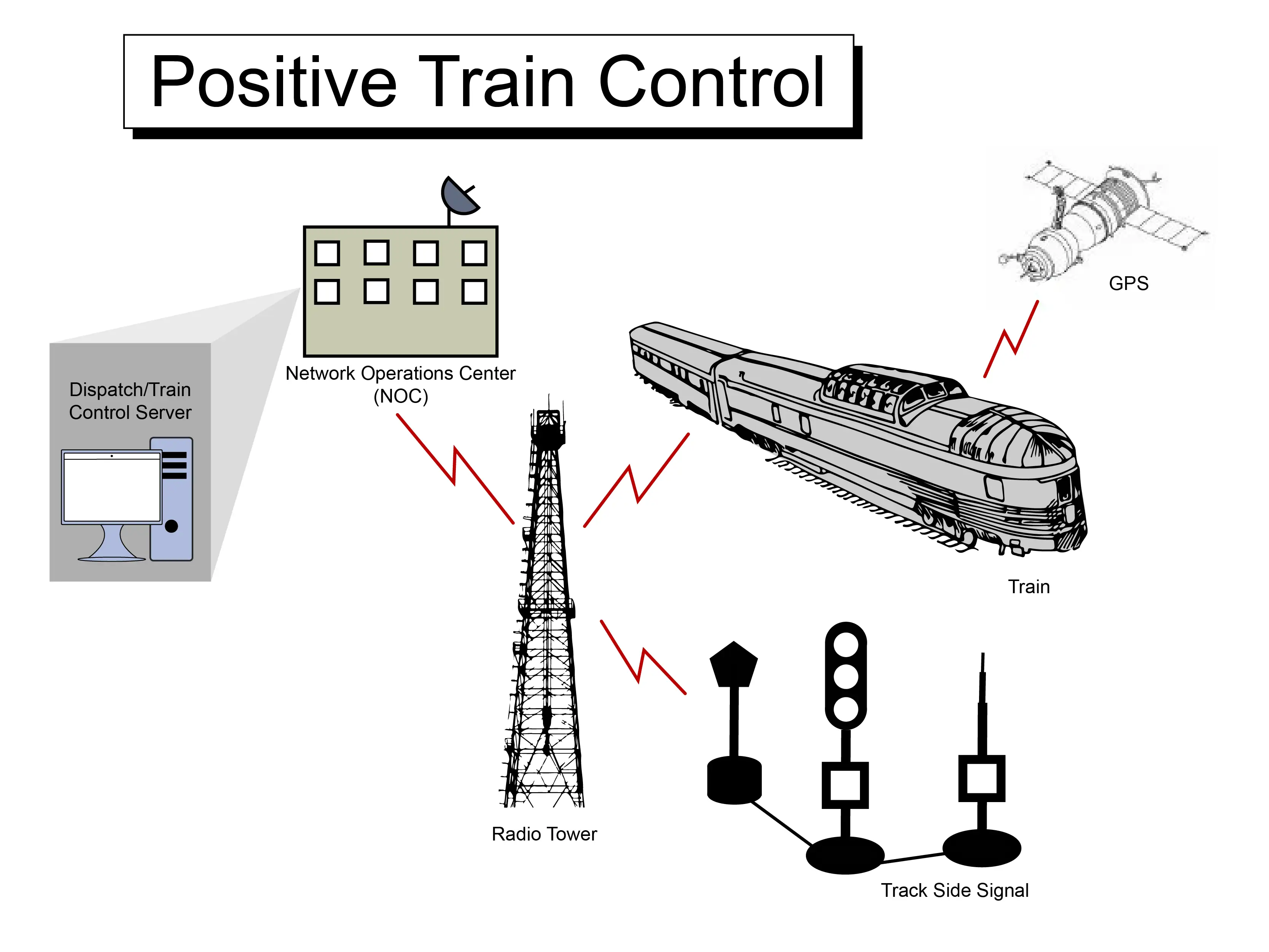

Positive Train Control (PTC) is one such technology that is becoming increasingly popular at railroad trade shows. PTC is a way of applying remote control and navigation technologies to prevent collisions and other railway accidents. Essentially, a train will report information about its speed and location to a movement authority which will determine whether or not the train is traveling at a safe speed, maintaining a safe distance from other railway vehicles, and is otherwise where its supposed to be. If the train is outside these boundaries, equipment onboard the train will automatically enforce the rule of the movement authority, preventing unsafe travel (i.e. slowing or stopping the train).

As a result of the September 12, 2008 collision of a passenger and freight train in California, positive train control became a federally mandated technology. According to the Rail Safety Improvement Act of 2008, PTC technologies must be in place and operational by 2015.

At the track level, PTC technology ranges from coded track circuits to wireless transponders that track train locations, which will inform monitoring systems, both inside and outside the cab of the locomotive, of the train's whereabouts and the condition of the track ahead.

Trains themselves will support onboard equipment to calculate the current speed and, more importantly, the train's braking capacity. Should a train reach an unsafe speed or braking distance, the train will automatically apply the brakes to bring the train within safe levels. The train will also likely receive GPS information related to position and upcoming movement-affecting issues - speed restrictions, work zones, or physical problems on the track, merely alerting conductors of issues at first but ultimately taking appropriate safety actions if engineers on the train do not.

Most railroads will also maintain a central office for PTC monitoring and control as well, rather than monitoring trains individually and from different locations. From the central location, controllers will be able to monitor all the trains on their tracks rather than monitoring data coming from individual trains. This means maintaining a complicated network. PTC Network downtime could result in loss of train or track visibility, traffic slow-downs, safety threats, and, potentially, penalties for failing to adhere to federal law. Only a few moments of network downtime could cause sever damage should a train derail or crash, not to mention the potential loss of life. These are just some of the reasons PTC is a critical component to railroad services.