Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayYour RTU collects a lot of data with its discrete, analog, and other specialized inputs, and that helps to build your situational awareness of a remote location that might be hundreds or thousands of miles away. Sometimes, you'll realize that you need to take action.

Imagine that you have a commercial power failure at a site. You're remotely watching your backup battery levels drop, and - at a certain point - it's time to turn on that generator.

If you don't have control relays on your RTU, you won't be able to turn on a generator that accepts a standard 5 VDC activation signal. Imagine how silly it would be to drive out to a remote site to press a button.

That's why most modern RTUs do have control relay outputs. With them, you're able to remotely activate just about any piece of equipment.

In other words, control relays are basically a switch that controlled by electric current. A control relays are coils that have electricity sent through them. When the electric current passes through the coil, the current generates an electromagnetic field that then works to operate the electrical device.

In our generator example, you're able to turn on that generator without even getting up from your desk. You're saving time, labor expense, fuel, and truck wear and tear.

Sure, it's great to be able to remotely control equipment, but your attention is still required to manually operate a control relay. What if your RTU was smart enough to automatically take action?

That's exactly what you get with a quality RTU. You'll find different trade names for the technology (ex. "Derived Controls"), but what matters is that you can pre-program rules for each control relay. Whenever the conditions you specified are met, your RTU will automatically activate ("latch") that control relay.

Going back to our original generator example, you wouldn't be required to use the RTU interface at all. Commercial power would fail, your batteries would gradually drain, and - when your remaining batteries hit a pre-programmed low threshold (ex. 20%) - your RTU would latch the relay and turn on the generator. Of course, you'll get a notification of each alarm condition and the relay activation, but your RTU won't allow the site to go dark if you aren't paying attention.

There are, in fact, different kinds of electromechanical relays. There are technical differences between various types (Form A vs. Form C, for example), but a detailed explanation of these types is beyond the scope of this article. If your connected equipment demands a certain type, just make sure your RTU matches.

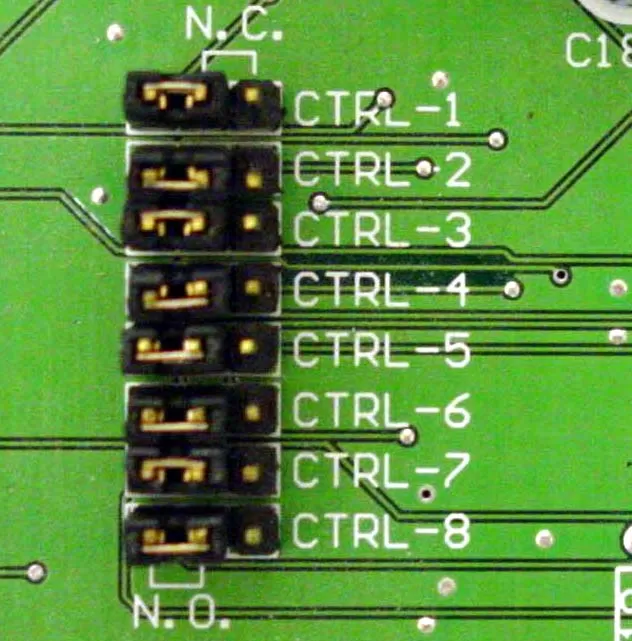

Also, make sure you're setting your switch relays correctly for either "normally open" or "normally closed" operation. A "normally open" (NO) relay will be open when not activated (its "normal" state), but will latch closed when energized. A "normally closed" (NC) relay is just the opposite: closed unless it becomes energized. Your engineering decisions will determine whether you need NC or NO relays, but make sure you pick an RTU that matches your need (or gives you the choice to set each relay to either setting).

Of greater significance is the maximum amperage rating of the relay. Most relays that are performing simple control functions don't have to handle much electrical current. Many are rated at just a single amp.

Even when they're starting up something much large (ex. generator), they only need to supply a small amount of current. A solenoid uses this small current to latch a bigger relay between the battery and the starter motor, and the generator fires up (this is the same way your internal-combustion car starts up).

For this reason, you don't need high-amp relay devices in most situations. Standard 1-amp relays will do just fine.

In other situations, however, you WILL want to control power directly. Think about a remote-controlled electrical outlet you might buy to plug into your wall. You plug a lamp into that outlet, and - when you press the remote control - the outlet box toggles between supplying power and supplying nothing. All the electricity that reaches your lamp must flow through the box's relay.

Now, imagine that you have a large server instead of a lamp. Sometimes it freezes, and you need to power cycle it. If that server is located at a remote site, you'll want to toggle power remotely rather than driving out there.

You can install an RTU with PDU (Power Distribution Unit) functions that include high-amp relays (typically 10 amps or more). These larger types of relays can supply sufficient power to your server without overloading.

Again, because you're in an industrial site and not a home, the "remote control" from our example becomes some type of remote-management protocol, most commonly SNMP over LAN.

With high-amp relays, your RTU is able to remotely toggle power to multiple pieces of gear, allowing you to activate/deactivate/reboot equipment without leaving your desk.

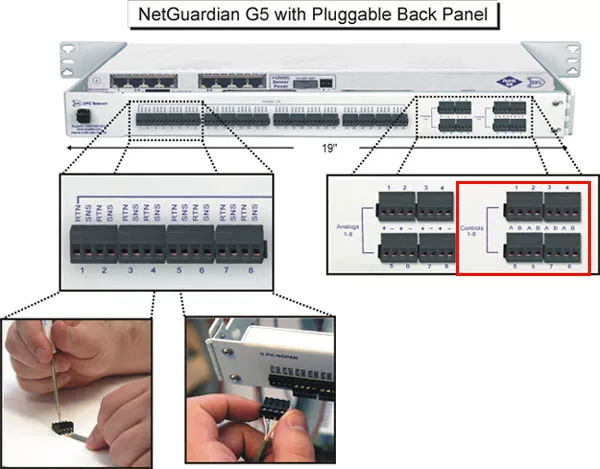

There are various connector types that are used for control relays. There really isn't a definitive standard.

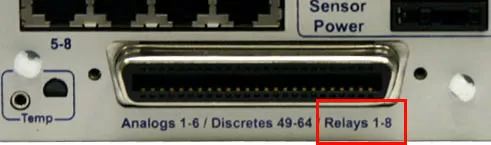

Some RTUs, particularly if they have a lot of discretes, analogs, and controls, will use a few of the pins on a 50-pin amphenol for each relay. Others with lower capacity may use smaller connectors to terminate.