Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayIf you have remote locations in your network that rely on microwave for data transport, they're probably fairly remote. You need remote monitoring, and that generally takes the form of an RTU. Most microwave sites aren't tremendously large, but they do have some requirements.

Here's a collection of the common items you should probably be monitoring via RTU at remote microwave sites where you have a diesel (or propane) generator. These aren't exact counts, by any means, but they should give you an idea of what to look for when you're doing your site survey.

Generator Tank Level, Run Status, & Output Voltage

You depend on your generator during extended commercial power failures (or even more frequently at very remote sites). You need to know that it's going to work.

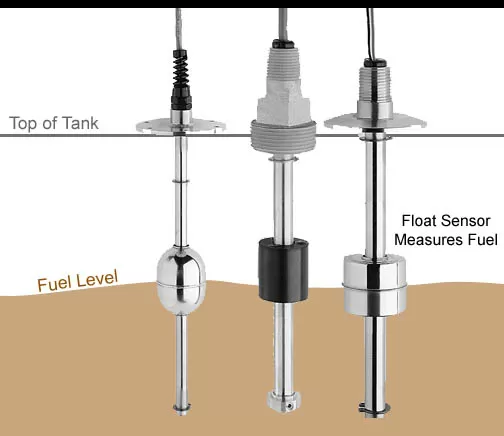

That means monitoring several aspects of generator performance. The first thing you need to know is how much fuel (usually diesel or propane/LPG) you have in the tank. Your generator can't run without it. This involves an external machine-readable fuel gauge (various styles are available) and one analog input on the RTU to attach the sensor. (+1 analog input)

You also need to monitor run status on the generator. If you see your generator kick on, you'll know that it's properly executing its regular exercise schedule (or your battery plant is running empty and the generator has reacted). You could also use a control relay output to remotely activate/deactivate the generator using your RTU. (+1 control relay, +1 discrete input)

Finally, you want to know that your generator is outputting the right voltage. Just like any power source, you need to know that you're within the voltage ranges accepted by all connected devices. If voltage starts to move outside this window, you need to react quickly by performing fast generator maintenance. (+1 analog input)

Battery Plant Status

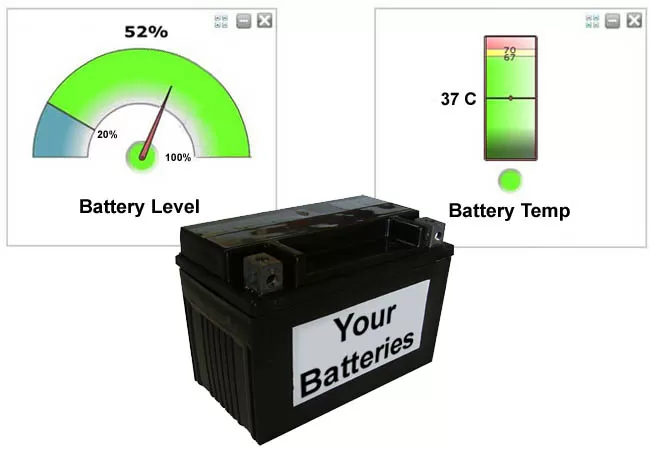

Your battery plant is your first line of defense when commercial power fails. You need to know how much power you have remaining. You can tie the string output voltage to the RTU for monitoring, and your RTU will extrapolate "battery life remaining" from that voltage measurement.

In fact, some of the better remote terminal units will have their power input(s) internally tied to an analog circuit. That reduces your wiring requirements, as the very same wires that are supplying battery-plant power to your RTU are also being monitored for voltage.

Battery temperature is also a good general measure of battery string health. A temperature that rises too high is a strong indicator that something may be wrong.

There are some very granular battery-monitoring systems available that tie a sensor pod to every cell in your battery string, but these tend to be quite expensive (to the point where many people say "I could replace my entire battery string anyway for less than what that monitoring system costs").

A pair of analog inputs (1 for voltage, 1 for temperature) are a good, baseline monitoring technique that you can install at a relatively small cost. (+2 analog inputs)

Microwave Transmitter Status

Your microwave system provides the vital communication link between all your remote site equipment (and, ultimately, your customers) and your central office. You have to know whenever it encounters problems.

Most microwave systems have a few discrete points they use to report problems. If you wire those into the discrete inputs on your RTU, you'll know when you need to react.

Common discrete alarms for microwave systems include: forward reflected power beyond tolerance, high noise, and transmitter failure. Let's assume, for this example, that those are the three discretes that our RTU must accommodate. (+3 discrete inputs)

Tower Light Illumination

Most transmitter towers fall under FCC/FAA regulations for beacon/obstruction lighting. You have a legal obligation to keep your tower lights online to protect aircraft.

Although exact lighting design requirements can vary, you must monitor the lights against failure. Some companies still have a person visually check the lights every day, but most at this point have chosen to deploy an automatic monitoring system (an RTU) instead.

If you have two sets of obstruction lights, and each uses a single discrete output to report failures, then your RTU will need two discrete inputs to monitor your tower lights. To remotely activate the secondary set when the primary fails, you should tie each set of lights to a control relay output. (+2 discrete inputs, +2 control relays)

Status of Revenue-Generating Equipment

We've already covered most of the typical equipment at a remote microwave site with a diesel generator. So what's left?

The remaining equipment you need to monitor and control is based on your industry. If you're a phone company, you'll have a switch (or softswitch). Wireless companies will have cellular equipment. Public safety agencies will have radio communications equipment.

All of this various gear is collectively called "revenue-generating equipment", because it's the equipment you use to generate revenue for your organization. This is the reason you have a remote site in the first place. All other gear plays a supporting role.

There will be a lot of variance in this category, so it makes little sense to give you a specific example. If you need help, you can certainly call DPS to get some expert advice.

For our example here, let's assume that you need eight discrete inputs and one control relay to adequately cover your revenue-generating equipment. (+8 discrete inputs, +1 control relays)

Adding it up

Now that we've done a basic site survey, let's total up what we have. The final tally is:

What RTU matches my requirements?

Now we have a tally of required specs, and it's time to choose an RTU that can handle the job. You also want to allow some room for growth.

Using an RTU filtering tool, enter your required specs. Don't be afraid to select slightly higher values to ensure you get a good fit.

Based on our requirements, the NetGuardian 420 is probably the best fit. It has 20 discrete inputs (6 above our requirement), 4 base analog inputs, and 4 base control relays. More inputs can be added with expansion "pods", so we're covered for growth in all three input types.

Once you've selected an RTU, take a look at its other capabilities. The NetGuardian 420, for example, has 4 terminal server serial ports. Learn about what these are and how you can use them. An investment in remote-site visibility is rarely wasted.

And what if you can't find a good RTU to match your specs? Find yourself a manufacturer who's willing and able to make customizations. If you need more than a few units (at least a dozen or so), you can probably even get a custom design delivered for no additional cost.