Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayProgrammable Logic Controllers, PLCs, are specialized computers used for partially automating and providing electronic control of electromechanical processes. They're designed with multiple input and output arrangements in mind, and typically built to handle extreme temperatures, electrical noise, and vibration often encountered in industrial processes.

PLC's are a type of Supervisory Control and Data Acquisition (SCADA) device: they monitor, automate, and provide a human interface for electronic control of processes. They take what would be a complicated mechanical process and provide the information and interface to make it an electronic one.

To provide this sophisticated level of process control, a PLCs gathers data through a series of discrete and analog sensors. It then either acts on the data in instances where it's been programmed to take action, or provides its user with relevant data so he or she can take action. And because they're software controlled, PLCs are supremely adaptable and allow for fast, relatively low-cost reconfiguration of processes.

Prior to the invention of PLCs, automating the same processes required hard-wired relays, cam timers, and drum sequencers. Any change in the process required a costly delay while relays were rewired and other equipment was fully recalibrated. PLCs were invented as an electronic way to circumvent these inconveniences, allowing for faster software recalibration of processes.

However, due to high initial costs of implementation, PLCs are typically only used for certain processes. They're justifiable where the requirements for automation are sufficiently complex and subject to change.

In recent years, many smaller industries have tried to circumvent the high cost of PLC implementation. They aim to do this while still satisfying their desire for automation by using programmable logic relays, or PLRs. PLRs are much like PLC, but with fewer inputs and outputs and are primarily used in light industries with fewer processes to automate.

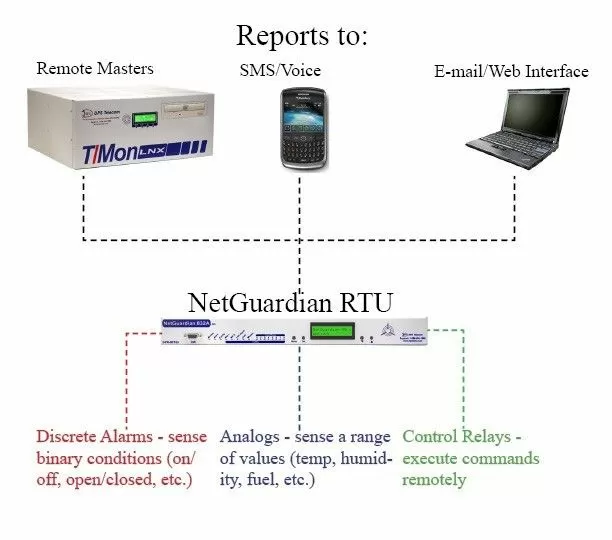

However, while PLRs provide high-level algorithmic control for automation, they often aren't scalable, nor do they provide many sensors for information reporting. That's why some businesses are now opting to utilize Remote Telemetry Units, or RTUs. These are small-scale, PLC-like devices equipped with a large number of discrete and analog sensors. They monitor processes and use control relays to execute basic controls. RTUs like the NetGuardian series have proven to be a low-cost solution for monitoring operations, optimized for network, communications, and transportation processes. They provide alarms to alert technicians to problems, and take action when specified to minimize any impact operations.

While PLCs and PLRs often operate in proprietary protocols, many of which aren't compatible across platforms. They require special training to understand and operate. RTUs from DPS come with their own understandable graphical interface and generally output in standard SNMP. They even report monitoring information from legacy or proprietary devices, so long as they output ASCII.

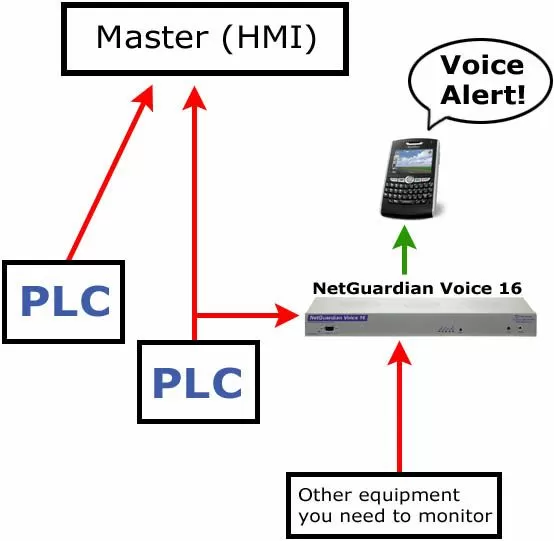

The NetGuardian series can also output plain-text alerts. It can report the status of controlled processes remotely. It can send alerts to technicians' e-mail or cell phone. Your technicians don't have to be specially trained or waste man-hours sitting in a control booth. The NetGuardian 16 series RTUs even offer voice alerts right to your phone. If something were to go wrong with your process or other SCADA devices, you'd get a voice alert detailing the problem without having to wait for a call from a dispatch center. RTUs help you stay on top of your most important processes, so when something goes wrong, you can take action immediately.

RTUs are a cost-effective alternative to PLCs and PLRs. They provide a similar level of information and automation at remote sites. They're also specialized for networking, communications, and transportation processes.