Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayBatteries keep your critical network or infrastructure online. They provide essential backup power when primary sources fail.

Whether you manage telecommunications systems, data centers, or industrial setups, actively maintaining the health of your batteries is a huge part of your job.

Without real-time situational awareness of your battery status, you risk unexpected downtime, costly repairs, and safety hazards. By actively measuring a few key metrics, you can decide when maintenance is needed or when a battery is nearing failure. Detecting early warning signs allows you to prevent major service-affecting outages.

"Battery monitoring" means consistently measuring critical indicators that reveal the condition of each battery in your system. This goes beyond occasional voltage checks. You also have to track each cell's internal resistance and temperature over time. By continuously evaluating these metrics, you can catch early signs of deterioration.

As a battery ages, its internal resistance increases. It's a clear sign of reduced efficiency and capacity (and an early warning of eventual failure!). Monitoring this change alerts you when a battery is nearing the end of its life, allowing you to replace it before it fails during a critical moment.

Monitoring temperature can prevent overheating, which is a common precursor to equipment failure or even fires.

Without active monitoring, you won't know when your batteries are about to stop working. Your lack of awareness sets the stage for sudden and disastrous failures.

Ignoring your need for battery monitoring exposes your network to financial losses, legal challenges, and operational disruptions.

If your batteries fail without warning, the devices they power - critical infrastructure, communication equipment, or essential data systems - will shut down. For businesses and agencies with legal obligations for uptime (like telcos, power utilities, healthcare facilities, or emergency services), the impact of downtime extends beyond financial losses into serious safety risks.

Batteries not monitored for internal resistance or temperature can degrade over time, leading to overheating or even explosions. Such incidents not only destroy the battery but also damage the equipment it powers. If a battery failure triggers a fire or electrical surge, the damage could extend to routers, servers, or other expensive infrastructure. At DPS, a client once reported to us that hydrogen off-gassing from batteries led to an explosion that launched a hut's door over 100 yards through a suburban area!

In many industries, failing to maintain reliable backup power can result in fines or legal penalties. For example, telecom companies and healthcare providers are often required to meet specific uptime levels. When that happens, you can end up with fines or legal consequences. Non-compliance with industry standards can also damage your company's reputation, leading to loss of customer trust.

Unexpected battery failures complicate repairs far beyond routine maintenance. You will likely need to dispatch technicians on an emergency basis, which is significantly more expensive than scheduled service visits. These emergency interventions disrupt regular operations and strain your budget.

Many organizations rely on routine battery inspections and scheduled replacements to prevent failures. While these methods offer some protection, they fail you in critical areas.

Most organizations inspect their batteries only a few times per year. Between inspections, batteries can degrade, develop faults, or encounter environmental conditions that lead to premature failure. By relying solely on scheduled maintenance, you leave big gaps where issues can go undetected.

To avoid unexpected failures, some companies replace batteries on a strict schedule. While this reduces risk, it often means discarding batteries that still have usable life. Over time, this approach leads to unnecessary costs, as you're replacing batteries that could have operated effectively for additional months or years. Battery monitoring enables you to replace batteries based on their actual condition and not just their age.

Batteries don't always fail gradually. Sometimes, they transition from fully operational to non-functional without warning. Routine inspections and scheduled replacements can't provide real-time visibility into your batteries' health, so you won't catch sudden failures during a random visit. On the other hand, battery monitoring systems provide immediate alerts when a battery starts to degrade so you can intervene before it fails completely.

To fully protect your infrastructure from these risks, you need a comprehensive battery monitoring solution that tracks important values in real time. A reliable system should offer continuous visibility of the health of each battery in your network.

Your system should monitor the voltage, temperature, and internal resistance of each battery. These factors collectively provide a complete picture of battery health. For example, while voltage indicates the current charge level, internal resistance reflects long-term health. Temperature fluctuations are a leading indicator of risks like overheating.

Deploy a system that sends alerts when any critical metrics deviate from specified thresholds. This allows you to act quickly when a battery begins to degrade or shows dangerous temperature spikes. Real-time alerts help you address issues before they escalate.

Ideally, your battery monitoring system should consolidate all data into a single platform accessible from any location. Having all your battery health information in one place keeps your team organized and enables faster decision-making. Centralized data also aids in long-term trend analysis.

Whether you're monitoring a few batteries at a single site or managing a huge network with hundreds of batteries across multiple locations, your system should be scalable. You should be able to easily expand your monitoring system for new batteries or sites without overhauling the entire system.

If you're thinking the above challenges sound a little complex and scary, you're not wrong. That's something we see all the time when people call us for help.

DPS Telecom manufactures advanced battery monitoring systems that meet all these requirements. Our equipment tracks key metrics, sends real-time alerts, and scales across large networks.

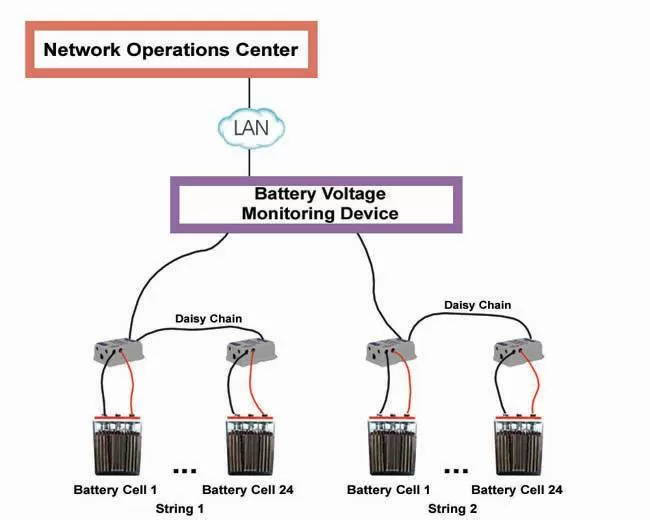

For example, the NetGuardian G6 series remote terminal units (RTUs) can come equipped with (optional) Battery Voltage Monitoring sensors (BVM sensors). These allow you to measure the voltage, temperature, and internal resistance of dozens of batteries at a single location. These RTUs also monitor other infrastructure equipment, giving you a centralized interface to manage everything from battery health to environmental conditions like temperature and humidity.

The other core component of an effective battery monitoring setup is a centralized master station like the T/Mon LNX system. T/Mon consolidates data from all your remote sites, giving you real-time visibility over your entire network.

Whether you're managing a handful of batteries or hundreds, T/Mon simplifies the process of monitoring and responding to potential issues.

Take control of your battery health. DPS Telecom's battery monitoring systems give you the real-time insights, centralized management, and scalable architecture you need.

Don't wait for your next unexpected battery problem. Call us at 1-800-693-0351 or email sales@dpstele.com today to start protecting your network.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...