Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayAlthough their complexities have increased over the decades, the job of an RTU (Remote Terminal Unit) is really quite simple. Your remote facility faces a variety of threats from things like HVAC failure, electrical outages, and simple equipment malfunctions. Detecting these via contact closure, protocol message, or sensor reading is not massively complex.

The challenge of choosing a good RTU is to find one that is actually reliable. Whether you have 5 sites or 500 sites, you'll be logging a lot of total time when things can go wrong. Success and failure is determined by whether your RTU simply, positively refuses to ever malfunction.

ESD is a potential killer of anything with a circuit board

ESD (Electrostatic Discharge) is a threat to anything that contains a PCB. There are hundreds of sensitive components on every board.

A single discharge, whether a simple "zap" from a finger or residual energy from a lightning strike, can cause critical equipment damage.

Your RTU needs to detect and report these events (and all others) reliably in your other systems, so it needs to be the most rugged gear you have. Otherwise, you'll never know when something has gone wrong.

Your RTU also has increased vulnerability due to the nature of its job. Since it has to be wired into everything to monitor effectively, your RTU is vulnerable to electrical surges from a variety of sources.

For that reason, you should always do your homework and purchase an RTU that is both designed and manufactured to resist ESD. You can also use the concepts I'll describe for you here when purchasing any other piece of gear that you need to be reliable.

ESD protection should be built into your equipment's design. This includes opto-isolation, protection diodes, PTC fuses, user-replaceable fuses, thorough grounding, and other methods.

You don't have to understand the fine details, but you should ask your manufacturer so you know you're buying reliable gear.

Ask some probing questions while you're shopping to see what answers you get:

Manufacturing Should Follow ESD Best Practices

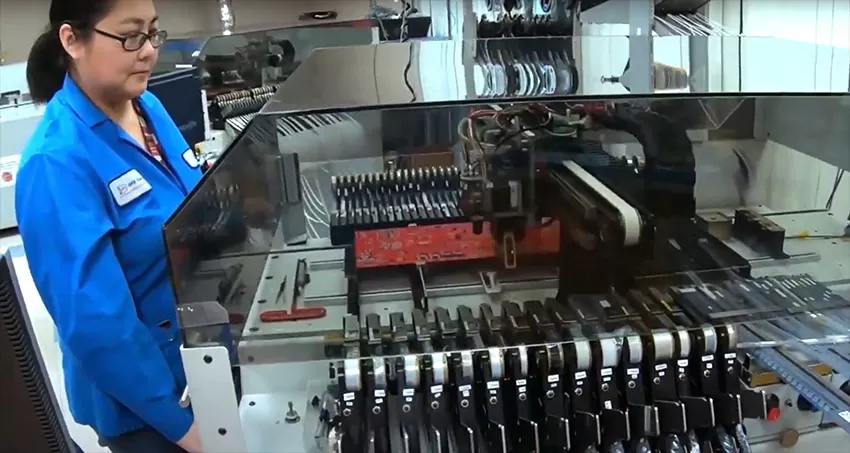

Quality electronic equipment is manufactured using best practices for ESD protection. Human touches are minimized with CNC SMT machines.

Whenever hand work is required, workers should be grounded thoroughly with wrist straps and heel straps. All work mats (usually blue in color) should be grounded.

When it comes to RTUs and other remote monitoring equipment, custom is sometimes necessary. After all, your network is unlike any other on the planet. It's obviously constructed from the same elements, but you have unique combinations and internal requirements.

This is where custom monitoring systems have tremendous value. When you go this route, you simply need to make sure that your manufacturer is experienced in delivering new products regularly. In manufacturing, this is known as "high-mix, low-volume".

Ask any RTU maker how often they design new things. If custom work is a rare exception, you're less likely to benefit from strong written procedures guiding that manufacturing.

This is as true of ESD protection as it is of anything else. Consider the different aspects of this we already discussed:

If your manufacturer designs new RTUs regularly, you can be confident that good ESD protection will be included. All inputs, outputs, and internal components will have solid protection/suppression against surges. This can be fuses, breakers, SPDs, or many other things.

Again, you don't need to know everything about circuit design. That's why you're buying equipment in the first place. Just ask some pointed questions to make sure you like what you're hearing.

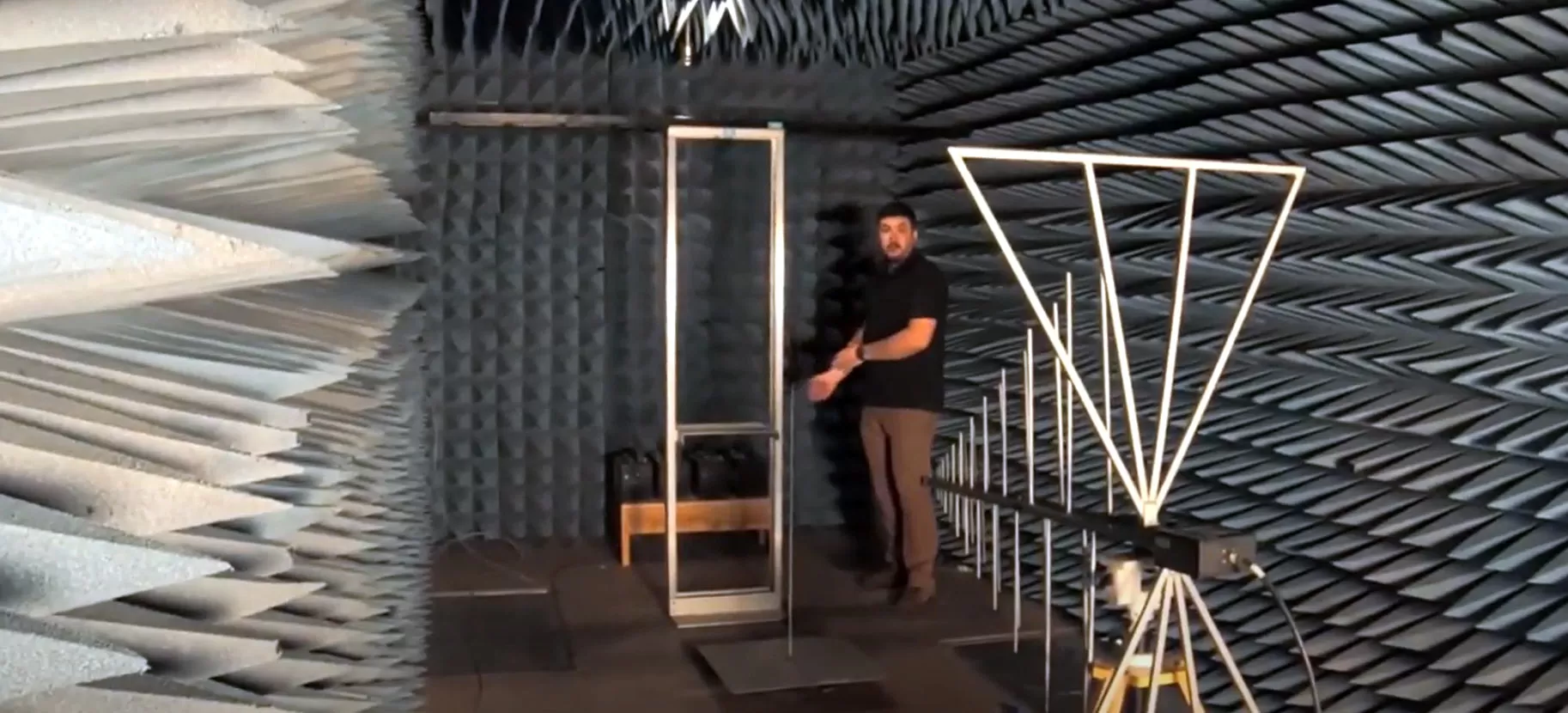

Similarly, a manufacturer with extensive experience will have good procedures in place for the actual manufacturing. This will begin prior to the creation of the first article and never stop. Workers will use ground straps. Chairs will have drag chains to stay grounded. Stray electric potential will have nowhere to hide.

It's one thing to write down what you say you do in an SOP or other procedure document. It's another to actually use that document day after day to guide your manufacturing.

You want to find an equipment manufacturer that follows all rules every single day. This helps ensure that you get a quality product in all aspects, ESD included.

Ask any manufacturer you're considering whether they manufacture their equipment in an ISO9001:2015 (or whatever the most current standard is) certified facility. Remember that products themselves are not certified against the ISO standards. Only a manufacturing facility can receive a certification from an independent body (ISO itself only creates the standards and does not certify anyone).

If ESD is a hot topic on your mind, I'd love to speak with you about it for a few minutes. I don't know everything there is to know, but I can certainly start a conversation with you.

If we go too deep for my background knowledge, I have many senior DPS engineers right down the hall from me. Each of them has designed the PCBs for multiple RTUs, using proven DPS design techniques to protect against power surges.

While we're at it, we can talk about everything you're trying to accomplish with an RTU. It might be that the device you're looking for doesn't quite exist yet. You might just help drive the development of our latest custom RTU. You can get exactly the device you need - and avoid paying for any features you'll never actually use.

Give me a call at 559-454-1600 or email me at sales@dpstele.com to discuss your project in more detail.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...