Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayWe all know how disastrous network downtime is to your organization. The remote monitoring of LP fuel tanks can be vital to your network, especially at unmanned sites.

Maybe you have propane as a back-up power source at your remote site. It's there to ensure you never have a gap in your network uptime. But that can all fail if you run out of fuel without realizing it.

Often, there are also legal obligations to remotely monitor the propane levels at remote sites (including NFPA 58 and NFPA 99).

Many clients come to us needing a remote monitoring solution for their propane tanks. Remotely monitoring your fuel level is important to help you save windshield time and (more importantly) to prevent network downtime.

Remotely monitoring your LP fuel level will let you know exactly what the status of your propane level is, from anywhere. This will help you prevent a network outage because you'll know when you need to send someone to refill the tank.

It will also prevent spending time and money sending technicians out periodically to physically check on the propane level at each site.

A remote propane tank monitor system is a small investment in comparison to the cost of a network outage, wasted windshield time, and citations for a code violation.

There are plenty of good reasons to remotely monitor the fuel level of your propane tanks. In some places, though, it's a legal obligation. For example, in the state of Washington, building codes require remote monitoring of LP tank levels.

And in some places, it's now legally required to remotely monitor your fuel level. I collaborated with two clients in the last year who needed an LP fuel monitoring system within a week to get up to code before an inspection. Both clients had a tight time restraint due to updated State Building codes.

This is a section of NFPA 99, which is a national code:

6.4.1.1.17 Alarm Annunciator. A remote annunciator that is storage battery powered shall be provided to operate outside of the generating room in a location readily observed by operating personnel at a regular work station (see 700.12 of NFPA 70, National Electrical Code). The annunciator shall be hard-wired to indicate alarm conditions of the emergency or auxiliary power source as follows:

(1) Individual visual signals shall indicate the following:

...

(d) Low fuel when the main fuel storage tank contains less than a 4-hour operating supply

In other words, the regulation states that the LP fuel level must be remotely monitored with a visual alarm panel.

Specifics and even tighter regulations may apply, depending on the state.

One client I worked with recently, a construction company in Washington, needed a remote monitoring solution to satisfy the Building Code requirements listed above. This is the solution I proposed:

From a technical perspective, I understand that you need:

Based on your needs I have quoted you two options:

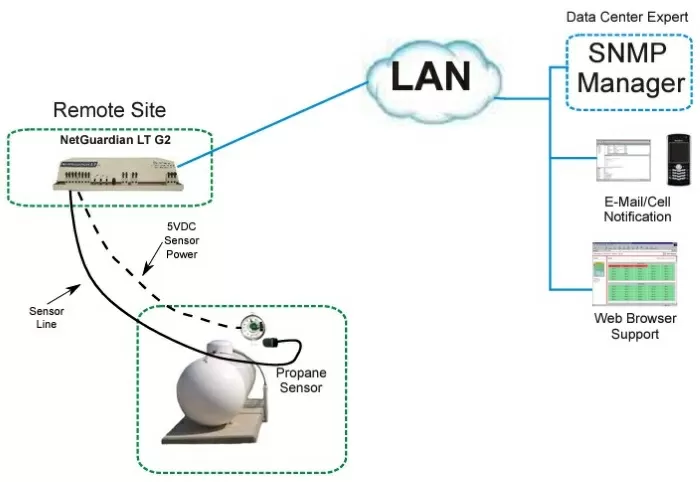

This client went with the NetGuardian LT G2 without the D-Wire propane sensor node. This was a perfect fit for their setup, with no extras. The products were shipped out to them within just three days, so they could get the propane tank remotely monitored before an inspection.

Remote monitoring often pays for itself in no time. Just the elimination of unnecessary truck rolls will save your organization plenty of time and money. And just one network outage can be much more costly.

For more information about implementing a remote propane tank monitoring system, give me a call at 559-454-1600. I can help you prevent network downtime and get your organization inspection-ready in no time.

Haley Zeigler

Haley is a Technical Marketing Writer at DPS Telecom. She works closely alongside the Sales and Marketing teams, as well as DPS engineers, resulting in a broad understanding of DPS products, clients, and the network monitoring industry.