Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayUsing SCADA (Supervisory Control and Data Acquisition) for wireless propane monitoring is crucial in industrial applications. It ensures the following:

If you're part of an industrial facility, you're most likely looking for propane monitoring because you heavily rely on things such as:

You are also probably responsible for monitoring multiple complexes. Therefore, you need centralized monitoring and relay capabilities to save windshield time.

With the proper SCADA manufacturer, you can properly gain real-time insights into things such as:

Let's take a look at how you can use sensors, data acquisition devices, and master stations to seamlessly automate your propane monitoring.

SCADA automates industrial applications through centralized monitoring and control. The different components of SCADA that help centralize your monitoring are:

All of these components come together to form a network that allows your staff to oversee multiple facility operations in one central location.

This is crucial in propane monitoring because:

Before being concerned about your wireless capabilities, first, you need to handle the data acquisition.

These are the 6 specific things that need to be established for a wireless propane monitoring system to be useful:

After incorporating all of these components, you now need to think about HMI (Human-Machine Interface).

This is what your operators use to read, understand, and interact with real-time data. This can be especially useful for control capabilities.

Your operators can monitor and control things such as:

They would be provided with:

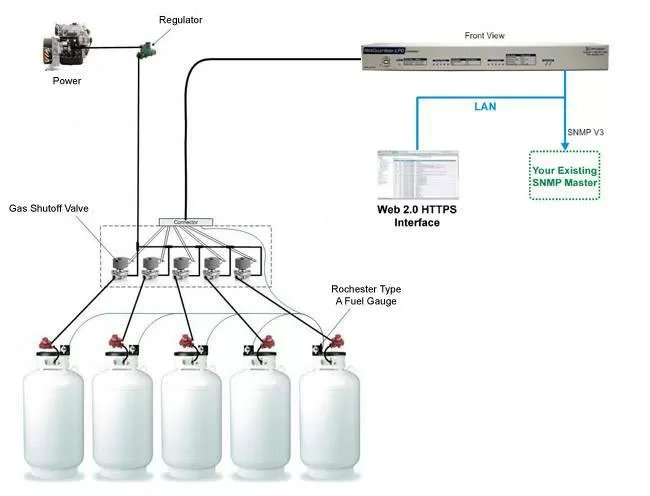

For the sake of drawing an example, please refer to the diagram below ↓

Too long of a downtime causes angry supervisors and angry customers. This can cause a preventable loss of revenue.

You may even damage your equipment if your propane tank runs on empty, such as if the motor burns up.

This damage is often irreversible and may cause you to spend money replacing damaged equipment. Sometimes this might mean a new motor, but often it means a whole new generator altogether.

Once you have decided that you want a fuel sensor to monitor your tanks, you now need to think about how you will monitor it.

Here are the most common roadblocks that make many people not want propane monitoring:

At DPS Telecom, we constantly have clients that need a reporting method that is easy to integrate and justify.

This caused us to develop wireless monitoring capabilities for installations that require it.

The NetGuardian LPG controller is a prime example of wireless propane monitoring. The LPG controller allows you to easily remote manage 4 liquid wireless propane gauges.

That wireless propane gauge would then relay whether a tank is close to empty or too full, and the LPG controller would close the empty tank valve and open the next one.

DPS Telecom developed the method mentioned above while tending to a client's specific need, and that solution was then repeated across similar applications.

We ask our clients to treat us like their own personal engineers. This allows us to continuously develop and improve our SCADA system capabilities.

Therefore, if you have any application that you haven't found a one-stop solution to, we can help you achieve just that.

If you think you have an application that we might be able to partner up on, or if you have any unanswered questions, please feel free to reach out.

Even if we can't find a solution together, I will be more than happy to try my best and send you in the right direction.

Call 1-800-693-0351 or Email sales@dpstele.com

Ziad Alezabi

Ziad Alezabi is a Application Documentarian at DPS Telecom. He reviews successful DPS client projects and reports on the best practices that you can use to successfully reach your own project goals.