Download our free Monitoring Fundamentals Tutorial.

An introduction to Monitoring Fundamentals strictly from the perspective of telecom network alarm management.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayEquipment monitoring allows you to check the status of your valuable equipment investments - even when you're not anywhere near that equipment. This is very common in telecommunications, utility, and transit environments. The network is built on physical equipment, and that equipment is seemingly everywhere within the service area (which can cover multiple states or even an entire country). Many of the remote locations that must be monitored are very far from civilization, making them vulnerable to extreme weather and opportunistic thieves and vandals.

So what sort of equipment is typically the subject of "equipment monitoring"? Here's a quick list of the most common equipment types:

And how is equipment monitoring accomplished? At the most basic level, a single standalone device can be installed at a remote site to collect system alarms and report them back to you in a simple way. Alarm reporting from such devices is typically handled via cell phone text message or phone voice message.

The more capable equipment monitoring devices in this category can also "escalate" alarms that are not acknowledged quickly by the first person called. In this circumstance, the next person up on the responsibility chain would be contacted when an alarm is not acknowledged within a predetermined period. This escalation can continue until the alarm is acknowledged, ensuring that a dangerous situation is not allowed to remain unknown for long.

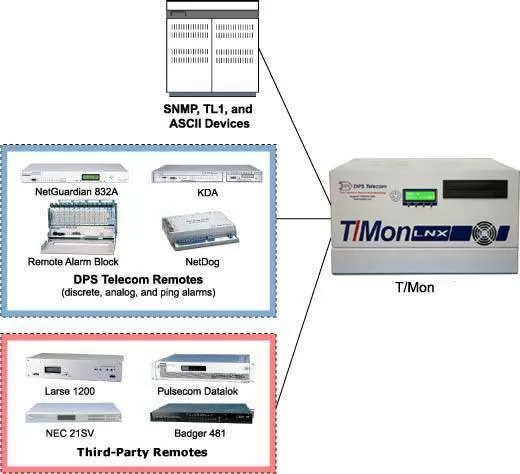

When the company has more than a dozen locations that contain equipment to be monitored, a much better notification option is a central master console. A central master console collects alarms from small remote boxes at each equipment site, aggregates them for a human user, and presents them on a display screen for review. A central master's display screen can include a geographic map of the region being monitored to support intuitive review of alarms and much better situational awareness during a crisis.

Of course, many smaller companies choose to contract with a dedicated equipment monitoring company so that they can focus on their other activities. This can be a useful short- to medium-term solution, but any company growing beyond a "small" size can really reap the benefits of bringing monitoring in-house.

Beware: DO NOT let your equipment monitor itself. It's always much better to deploy a dedicated equipment monitoring system. If you allow any piece of equipment to monitor itself, you run a very serious risk of losing visibility when that equipment fails. When this happens, you will have extracted precisely zero benefit from your equipment monitoring setup. To be effective, your equipment monitoring system needs to outlast all of the equipment that it monitors.

So, how much equipment monitoring should you deploy at each site? That depends greatly on how much equipment needs to be monitored there. You don't want to install more monitoring capacity than you need, but you also don't want to be "stuck between a rock and a hard place" by purchasing an equipment monitoring device that doesn't have enough capacity to meet the needs of a particular site.

Even though it's important not to choose monitoring has way too much or way too little capacity, you do want to choose just a few remotes that your technicians will need to learn and install. Choosing a custom-built alarm remote for each equipment site is certainly possible, but it creates an installation nightmare.

So, what benefits can you expect to extract from having an effective equipment monitoring system? First, your technicians should be spending a substantially lower number of hours each week driving to and from remote sites when you have proper network visibility. If they can see what's going on with equipment right from the central office, there's very little need to make a trip just to discover a problem. Instead, all trips can be directed towards solving a problem, and a technician can take the right tools and equipment to correct the issue in just one site visit. This is something you never could have dreamed of achieving without an effective equipment monitoring solution.

Also, if you choose the right equipment monitoring system, you won't be paying any recurring licensing fees. These make purchasing monitoring gear a recurring expense instead of a one-time expense. Licensing fees are a purchase that keeps on taking, month after month, year after year.

One recent DPS Telecom client had roughly 20 tower sites that needed to be monitored. The goal was to monitor site equipment (transceivers, etc.) as well as the tower beacon lights that are required by the FCC/FAA to protect aircraft from unknowingly crashing into the tall towers. There was no existing standard communication transmission like LAN, POTS, or serial at the site, so this client was looking for a wireless solution. This client needed:

In the end, a wireless CellVoice or wireless NetDog remote proved to be the right solution to monitor the equipment at each tower site.

Another client named Joe came to DPS looking for a small RTU to monitor equipment at about 6 sites where he needed remote visibility. Joe needed about 8 discrete alarm points, 3 controls (relays), 1 serial port for COM port redirect, and 4 generic analog inputs.

Drive time was 2 hours each way to his one site. This puts wear and tear on Joe's vehicle and costs a lot of money for gas (not to mention the wasted time).

Joe had a couple of sites that were solar powered and had diesel generators that run when the panels do not create enough electricity. The generators can have problems when they have to kick on and off a couple times a day. If the generator does not start, the site will have the inverter cut out so the batteries are not drained to point of damage. This will cause the site to go down.

For these reasons, Joe elected to deploy a NetGuardian equipment monitoring system at his distant site.

Related Topics:

Remote Equipment

Related Equipment Monitoring Devices:

Central Master: T/Mon

Alarm Remote: The NetGuardian 832A G5