Download our free Monitoring Fundamentals Tutorial.

An introduction to Monitoring Fundamentals strictly from the perspective of telecom network alarm management.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat Today

Do you use either propane or diesel as a primary or backup power source at your remote sites? If you do, you know that running out of fuel has major consequences.

Your remote sites need fuel (propane/LPG or diesel) to stay online when commercial power fails. With limited battery plant capacity, you never want your fuel tanks to unexpectedly run dry. Imagine the expense and stress of rushing a refueling truck out to your site and hoping it gets there in time.

But tracking your propane or diesel levels is complicated. You have a lot of sites, and they consume fuel at different rates. You can schedule routine refueling trips based on average consumption, but that's not very efficient and you'll still get the occasional surprise.

With modern fuel sensor technology, it's now possible to use fuel sensors to remote track fuel levels. You and your team will get alerts whenever fuel runs low. You'll be able to refocus your experts on more important work because refueling will suddenly be a simple process to manage.

So, you need fuel tank monitoring equipment that monitors your fuel levels in near-real-time. It sends you low-fuel alarms. It even toggles between tanks when one is running dry.

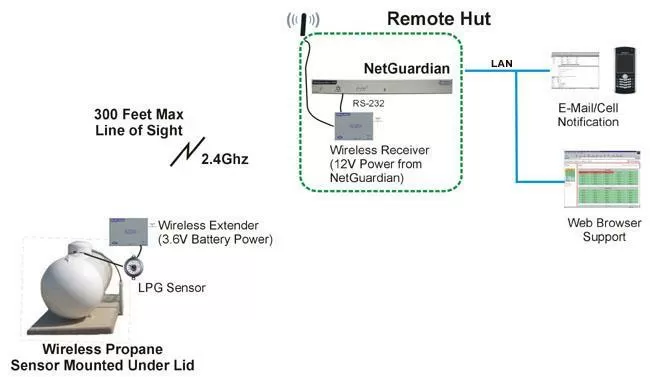

Let's start by looking at an example site:

As you can see above, the key elements of fuel system monitoring are:

Your fuel monitoring system shouldn't operate in isolation. Instead, you should integrate it with your existing network alarm system. This makes sure that fuel level alerts are part of your broader site visibility strategy. With the right monitoring solution, you can bring all your critical alarms - including fuel levels, generator status, and battery backup - into one centralized platform.

An RTU - such as a NetGuardian - acts as the central hub. Your RTU collects data from fuel sensors and transmits it to your existing alarm master or SNMP manager. This means you don't need to check multiple systems - you can see all your critical alarms in one place.

Key advantages of integration include:

No. You don't need to penetrate the walls of your tanks to set up fuel level sensors. You just need to choose an appropriate sensor for your needs. There are several types of fuel sensors available:

Many companies often overlook generator monitoring of their propane/diesel fuel levels. This means, at any given moment, you're vulnerable to running out of fuel and quickly into a power outage. With your uptime directly depending on your generators as a power source, it's simply too risky to leave such a high-value piece of equipment unmonitored.

Tank level monitoring, just like most other elements of network visibility, offers two kinds of benefits:

Do you want to simplify your remote monitoring management to make things easier for you and your crew? Call DPS today to go over fuel monitoring and other monitoring solutions techniques to prevent unpleasant surprises:

1-800-693-0351 or sales@dpstele.com