Download our free Monitoring Fundamentals Tutorial.

An introduction to Monitoring Fundamentals strictly from the perspective of telecom network alarm management.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayIf you are a train operator or work for a railway company managing telecom resources, you know that the United States Government has mandated total implementation of positive train control (PTC) by December 31, 2015. While there have been heated debates about the exact cost and benefits of PTC implementation, everyone it agrees that it will be a very large and expensive project for train monitoring and control systems.

You're probably heavily focused on the actual devices that go into your planned PTC implementation, and that's definitely how you should devote most of your thinking. Nonetheless, I've written this article to make sure you don't forget one of the most important and budget-saving aspects of any equipment deployment: remote alarm monitoring and control. Positive Train Control (PTC) encompasses many new technologies - giving you an important opportunity and responsibility to minimize and offset costs with effective remote monitoring gear.

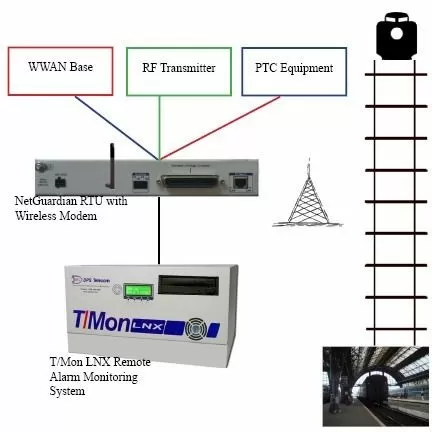

In order to minimize the cost of your PTC implementation and improve the reliability of the system itself, one important thing you must do is deploy PTC network monitoring equipment within your telecom support network. PTC will substantially increase the amount of IT gear in wayside enclosures and other critical locations. You're going to need expanded monitoring capacity and your system had better work better than ever.

Talking about theory has some use, but it will probably be helpful now to review some specific monitoring devices. One master station that is already seeing deployment in PTC projects is T/Mon. With a proven history at BNSF, New York City Transit (MTA), and other major railway companies, it's no coincidence that T/Mon is being deployed as part of the PTC effort.

So what makes T/Mon and similar masters suitable for use by the largest railway companies? Certainly device and alarm point capacity is critical. National railways are truly massive in scope. Any alarm master that doesn't have the database capacity or processing power to handle "alarm storms" from thousands of remote devices just won't work at a major railway.

Geographic disaster recovery is also an important ability in any large network. When you absolutely, positively need a network management system online 7x24x365, you can't simply be running a single master station. T/Mon is a very stable platform with reliable hardware and redundant hard disks, but any electronic device can still fail.

Any alarm master you select for use in a Positive Train Control scenario must be capable of some kind of redundant operation. In the case of T/Mon, you can run two T/Mon master stations simultaneously. While the primary master manages your network, the second's sole purpose is to stay in sync with the primary at all times. Should the primary ever fail, the secondary will take over within seconds.

While you can get a lot of hardware redundancy benefit by having two redundant T/Mon masters in the same rack, an even better choice is to locate them far away from each other. So long as they're linked via LAN, the automatic fail-over functions will operate correctly. This means it's even possible to locate your T/Mon masters across the country from each other. This improves reliability even further, as a hurricane, flood, or other natural disaster in one region will not take down your only "nerve center."

With equipment spread out across thousands of miles, you obviously can't monitor using only central master stations. You're also going to need a fleet of reliable remote telemetry units (RTUs) to collect alarms at each of your remote locations and report them back to the central master(s).

A different set of "best practice" product features are required in a reliable alarm remote that will monitor PTC and other systems. First and foremost is the ability to withstand the extreme conditions in your wayside cabinets and other structures. If your alarm remote doesn't have an industrial temperature rating, it probably isn't suited for most of the track-side cabinets.

Wireless alarm reporting capability (ex. CDMA or GSM/GPRS) is also helpful when you're dealing with many very remote sites. You'll need an alternative for sites out of cellular coverage areas, but wireless provides an important primary or backup reporting method on remotes that support the technology.

The PTC gear you choose is very important. You should definitely do your homework and choose the right manufacturer. Because it is so important, you must not forget to protect your new PTC systems with good remote alarm monitoring and control. If you fail to do so, you'll inevitably get stuck in a quagmire of cost overruns and upset customers.

This article has given you a basic introduction to the important considerations when choosing a monitoring system to support your PTC deployment. For more monitoring best practices, click around the site. There are plenty of additional tips in the downloadable white paper series and other online articles. If you have specific questions about your PTC application and how remote monitoring will interact, send email to sales@dpstele.com or call 1-800-693-0351.