Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayThe data transport you have available will often determine the difficulty of your RTU search. If LAN is available, you can choose from alarm remotes offered by a wide range of manufacturers.

Your job gets a lot more difficult when you have special transport requirements. Consider the example of a site that doesn't have LAN but does (or very inexpensively could) have T1. An outside-plant (OSP) site like that requires a much more accommodating RTU manufacturer who can offer native T1 support.

Let's walk through an example scenario. First, we'll address the topic at hand: getting an RTU that can support T1, regardless of its other capacities and functions. Second, we'll walk through the same analysis you'd need to complete for any RTU at any site: how many inputs and outputs does it need, and what special requirements must it meet?

Finding and choosing an RTU with native T1 support

Any RTU you're going to deploy at a site that doesn't have LAN must have an alternative. In this current scenario, you need to find one that specifically does support T1.

So, what manufacturers offer native T1 support? Look for one with small-business agility, because high-mix, low-volume companies will have a much broader selection than those who sell massive quantities of just a few.

There are also a few design considerations you must make. What protocol will your T1 use? Two of the most common are FrameRelay and PPP. Whatever it will be in your case, make sure your RTU is compatible.

Next, don't overlook you chance to supply LAN to other LAN-only devices at a remote site. Yes, you're deploying an RTU. Its primary job is always going to be remote monitoring and control. Some, however, also have an ethernet switch on the back panel. Combine that will native T1 and a bit of engineering magic, and your RTU can "break out" LAN for several external devices. This goes way beyond a typical alarm remote, performing the function of a dedicated transport card that would otherwise be an expensive additional purchase.

Finally, don't fumble your future by purchasing an RTU that only supports T1. Someday, you may very well get LAN rolled out to this location. Do you really want to have yet another purchasing and install headache? Don't go down that road. Deploy a remote that supports both T1 and LAN. When you get LAN out to the site, unplug the T1 WAN port and plug LAN into the LAN port. Your transition will be complete within minutes.

Monitoring the revenue-generating equipment you have at this site

Now that we have data transport sorted, let's not forget that this is still an RTU. It has to monitor and control various other equipment and environmentals.

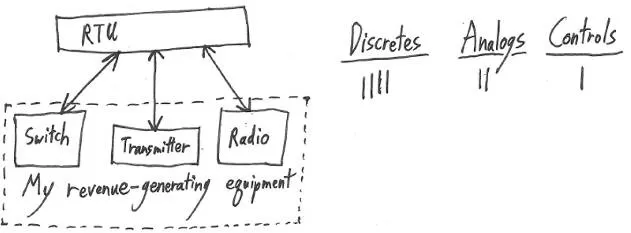

Take stock of your revenue-generating equipment (we call it "revenue-generating" because it's the gear that directly provides service to your customers). It's difficult to offer specific guidance here, because there's a lot of variance by industry. If you're a phone company, you'll be monitoring phone switches and other gear that enables calls for your customers. If you're a power company, you'll be monitoring substation IT gear. Public safety agencies will have network equipment and radio systems.

Fortunately, the process of calculating capacity requirements does not vary much among these diverse industries. Here's the process you must follow:

Manufacturer specs will tell you what kind of outputs a device has. A phone switch, for example, might have 4 discrete outputs that report card failures, transport failures, high traffic. If you don't have access to manufacturer documentation (ex. they're out of business), just look at the equipment itself. Most output ports are labeled somewhat intuitively, although you may need to decipher a few port-label abbreviations. A quick web search can be surprisingly helpful, even for obscure equipment. You're probably not the first person to encounter this problem!

So discretes, then, are fairly simple. Analogs, however, require a more complex analysis. Most equipment won't have any ports labeled "Analog Output 0-5v". With analog inputs, you're more commonly measuring power voltages or taking in data from environmentals. You need to ask yourself what you want to protect using monitoring.

Temperature sensors are the most common analog sensor to tie into an RTU. For the ultimate monitoring granularity, put temperature sensors near individual pieces of revenue-generating equipment. In most cases, a single sensor is adequate to cover a large area. Air disperses heat enough that any isolated heat spike will be detected within a reasonable time.

You should also monitor humidity. Not only does monitor for high humidity that could lead to liquid condensation, but rising humidity can be a sign of a water leak (although a discrete floor water sensor is a better tool for detecting such a leak).

Finally, you can decide to monitor input voltages to various equipment, but we'll pick up most of that later when we review our rectifier, generator, and battery plant in the next section.

What about controls? Just like discretes, these are fairly simple. You just need to look at your remote-site equipment (or documentation) and find any control input points. Do you have any ports labeled "on/off" or "5V trigger"? That's a clear sign that equipment will accept commands from an RTU's control relay output.

This is a small site, so let's say we want one analog temperature sensor, one analog humidity sensor, and a single control relay to reboot our switch.

In total so far, for our revenue-generating equipment alone, our RTU will need:

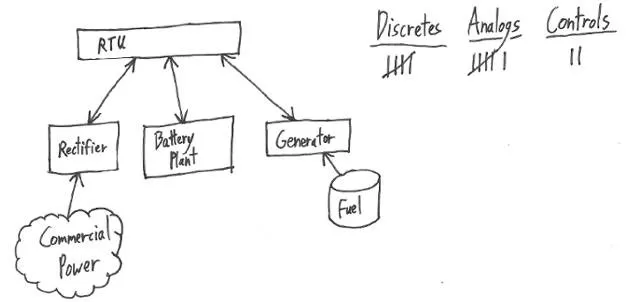

Power supply: Your rectifier, battery plant, and generator

Your gear can't run without power. That's why your sites probably have primary power (commercial AC), short-term backup (battery plant), and long-term backup (diesel/propane generator). Let's start from best-case-scenario power and work our way down.

Your rectifier takes commercial AC power and outputs DC power (generally +24v or -48v in the United States) for your equipment. Monitoring DC output voltage from your rectifier using an RTU analog input is a great way to track the power flowing to just about all of your equipment. If voltage drops during brownout condition (or vanishes when the power goes out), you can react to prevent equipment damage and a site ultimately going dark. If, for some reason, you can't spare an analog input, you can at least use a discrete power-out-alert sensor that will tell you when commercial power fails.

When commercial power goes down, your battery plant (Uninterruptible Power Supply) kicks in. That represents a few more things you should be monitoring. Voltage output is certainly one. On a battery, this measurement does double duty. Yes, you're monitoring power quality, but declining voltage output is also how you estimate remaining battery life.

One analog input on your RTU measuring voltage can give you huge situational awareness about your batteries and when then may run out. At least one temperature sensor on the battery string itself can help you detect battery damage early - before expensive equipment damage occurs.

Finally, dead commercial power and nearly dead batteries mean it's time for your generator to kick on and recharge your batteries. When that time comes, will you have enough fuel? Whether you use a propane (LPG) or diesel generator, a simple analog fuel tank sensor will give you tremendous confidence.

During an extended, widespread outage (ex. hurricane aftermath), your network of fuel sensors will help you prioritize your refueling truck dispatch to keep your sites running.

With a control relay, your RTU can directly control generator activation when it detects low battery-plant life.

Last, you want to know when your generator is actually running. This is important for a few reasons. First, it's great redundant visibility that you're having a power event. Second, you can verify regular generator maintenance "exercising" (ex. run 1 hour per month) that keeps the engine in good condition.

Should you not have enough analog capacity to actually monitor your fuel level, an RTU log of accumulated running time since the last fill up is a decent proxy.

Let's take a minute to recap our RTU I/O tally for this site's power supply:

Adding this tally to our previous subtotal for revenue-generating equipment, we now have:

There's no way that any single article could cover every thing you could possibly monitor at your site. A complete site survey is up to you, but here are some common items to look for:

To help us choose an RTU in this example, let's add 5 more discrete inputs to our total. That brings us to a grand total specification of:

Which RTU should I choose?

Good RTU manufactures make it easy to sort through your various options with a filterable "feature matrix". You just punch in your required specs (add a bit to cover growth) and see a list of options. Alternatively, you can call and talk to an expert directly, which you'll do anyway before making an investment decision. www.dpstele.com has a good example of a feature matrix for its NetGuardian line of RTUs. Using that feature matrix turns up two potential options:

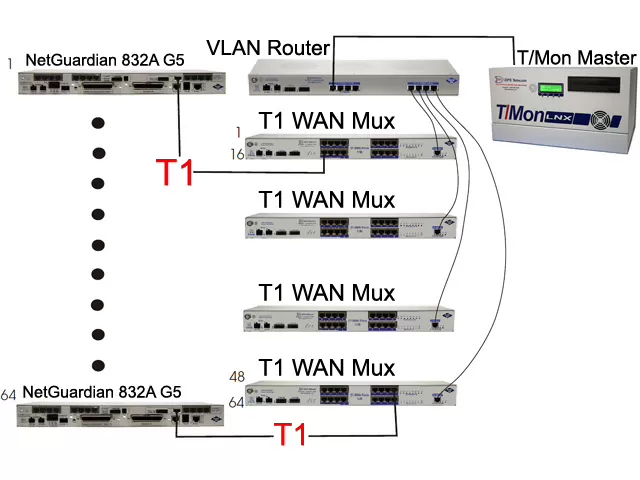

Remember that there are lots of possibilities if you're working with a good manufacturer. Just look at this T1 solution that supports VLAN:

As you can see, finding the right RTU involves a few simple steps:

If you need any assistance at any time with your remote monitoring project, call us at 1-800-693-0351. We're experts in this field, and we're happy to help you.