Download our free SCADA tutorial.

An introduction to SCADA from your own perspective.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat Today

Allen Pump Company (APC) has been a family-owned business for more than 55 years. It was started by father and son, Lan and Lee Allen. APC is now run and operated by two of Lee's sons, Steve and Chris, and they carry with them a vast knowledge of over 75 years of experience. The Allen Family has a deep understanding of the Gila River Valley where they are located. Curtis and Ty Allen (Steve's sons) and Ryan Allen (Chris' son) are fourth-generation at Allen Pump Co.

Over the years, APC has been a part of many projects, big and small. They have been on the leading edge with new products and even innovated some of their own to suit the needs of their clients. While their specialty is servicing vertical turbine and submersible pumps, they also have experience in mining-open pit dewatering municipal-drinking water and agriculture pumps, and much more.

In 2013, Gila Valley Irrigation District (GVID) hired APC to work on a SCADA project. "We were asked by the Gila Valley Irrigation District to install a SCADA system for a pipeline that was going to be constructed and put into place," said Curtis Allen.

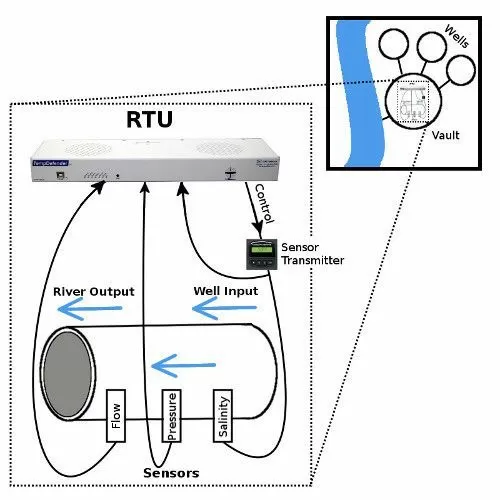

The project was the result of high salinity levels in the river that runs from one town to the next. The first town would divert water out of the river for agricultural needs, which significantly increases the salinity (salt level) in the river as it reaches the next town. With a new pipeline and monitoring system, GVID can monitor the salinity of the river at critical junctures and pump in clean water when the salt level is too high.

"They kinda said 'hey can you guys do this for us?' We didn't really know quite what to do, but we said 'we'd like to learn it'. So we said yes." APC was excited about the project, but needed a partner to learn the basics. "It's something totally new to us. We've never been involved in SCADA, telemetry, anything of that sort."

Through past projects, the GVID knew that Allen Pump was the company for the job. "We have a long-standing relationship with the irrigation district. They've hired us to do many many things for them in the past," said Curtis Allen. "When this project came up about putting in a pipeline and SCADA system, I think the trust that we have been able to build with them was key."

APC knew they needed to find a solution quickly, so they contacted a friend, Jay Okimoto of Crosswalk Technologies, for help. "We reached out to a good friend of ours that we know is highly technical in computer networking, and he agreed to help us try to find someone to do that for us."

APC had no previous experience with monitoring systems, so Jay Okimoto advised them of a few key features to look for. "We had a few things that we really latched onto, of course based on his knowledge and experience," said Curtis Allen.

They knew the importance of a flexible and versatile system. "We were looking for someone that had non-proprietary equipment that we could use. It was very important that the things that we implemented and integrated could work with various other types of equipment."

A system that could work seamlessly with other gear was a must. "We didn't want to set ourselves up for being locked in a box of 'we have to buy this type of controller, we have to use this specific sensor or flow meter'," said Curtis Allen. With this in mind, Jay got to work. "He made a lot of phone calls and discovered DPS Telecom," said Curtis Allen.

To ensure APC got exactly what they needed, DPS sent President Marshall DenHartog to field-test the system. "Marshall helped us to spec out the job. He told us what equipment we needed. He went out and did all the research about which sensors would work with which DPS RTUs."

With help from DenHartog, APC was able to see their ideas come to life. "Marshall coming out was really instrumental in the whole thing," said Ty Allen. "We had an idea of how we thought it would work, but it was all theory up to that point."

DPS Telecom specializes in making custom fit solutions built to the clients needs. "So Marshall came out and we did kind of a temporary setup. Temporary power, temporary communications," said Ty Allen. "He had it built to what he thought would work for our job. And then he came out and tested it on site for us. And he was a technical guy on the ground that could actually tell us if things were working."

DenHartog's expertise impressed APC. "He was amazing. We set up a picnic table down in this 12x12 concrete vault 10 feet below the ground. And there were a whole bunch of us guys down there with a picnic table and a laptop on there and DPS's RTU," said Curtis Allen. "Marshall said 'oh yeah, we just put these wires over here' and all of us said 'We don't know what you're doing, but it's working!'"

"Marshall was great too because we were asking 'Can we look at this? And from that can we see this?'" said Curtis Allen. "And I don't think we ever heard a 'No'. We were really impressed with DPS Telecom from that point on."

APC knew that, without monitoring, it would be nearly impossible to control and operate the pumps. "Well, we are putting in five pumps. We would have to turn on 5 pumps and put them into this pipeline. And we would send discharges into the river. If we ever wanted to turn it on, I would have to drive out there and physically drive to each pump site and turn on each one, and the same thing for turning them off."

Monitoring the pumps remotely saves APC time and money, as well as limits costly truck rolls. "It's 23 miles to get out to the site. And to drive around to each pump, I can get to each pump with in a matter of 10 minutes," said Ty Allen. "Turning on the pumps would take 10 or 15 minutes. Then after that, I would have to have some set schedule of salinity at this pump, this pump. Which would take probably an hour for a cycle to go through and do that."

"So if you wanted to monitor and make sure that things are running regularly, you would have to go out there at least once a day."

"The whole purpose behind this is to decrease the salinity of the natural river flow," said Curtis Allen. "So if this kind of system wasn't in place, I would have to be gathering manual salinity readings coming out of the pipeline. It's not just going out there and turning on the pumps. It's measuring water quality, turning on the pumps."

"And, at a moment's notice, if someone were to ask what quality of water are we putting into the river, I can look at it and say this is the EC that's going in. And if they ask for the quantity, then we can also give that to them."

With help from DPS, APC was able to find a perfect-fit solution for their monitoring needs. "I never had a doubt that the project was going to be a success," said Curtis Allen. "Marshall just had this confidence that we felt very comfortable with. We knew DPS Telecom was going to be able to come through for us."

To receive a price quote or ROI analysis...

Call 1-800-693-0351