How to Choose Battery Sensors that Won't Short-Circuit Your Battery Posts

By Andrew Erickson

June 10, 2021

As part of our ongoing mission to provide monitoring tools for remote sites, DPS builds a lot of battery monitoring equipment. Sometimes, it's as simple as monitoring the string voltage and maybe the ambient room temperature. In other cases, we build and sell an entire array of battery nodes (one per battery).

Last year's release of our revised BVM G3 battery sensors (measuring temperature, voltage, & internal resistance) led us to new client concerns and new product developments. This included a very strong push for DPS to answer an important question:

"How can I be sure that your battery sensors won't cause a battery short and an explosion?"

Clearly, you never want to add the risk of damage (or even injury and death) at a remote site. That's especially true when you're putting in a remote site monitoring system. The goal of such a system is to protect your site, so it would be terribly ironic if it actually caused damage.

Let's take a look at the typical causes of battery shorting, the risk of downtime/fires/explosions, and what we can do from a design perspective to minimize risk:

How do battery sensors cause dangerous short circuits?

Although it doesn't happen very often, a battery short caused by a connected sensor is a spectacular event.

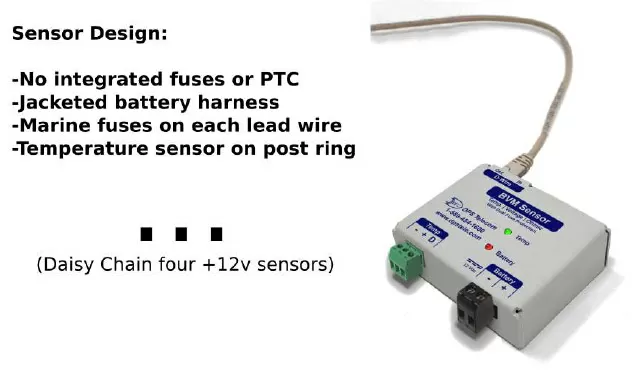

Sensors always present some conceivable risk of a battery short. In this snippet from a DPS proposal, note how the fuses have been moved off of the sensor board and down close to the terminal post rings on the wiring harnesses, as described in the note and pictured below.

Here are the most common ways that batteries get short-circuited by sensors:

- Frayed wires can bypass the sensor entirely. Because a battery sensor must monitor the voltage (and internal resistance, etc.) of an individual battery, it must necessarily connect to both the positive and negative posts. Then, because sensors are usually quite small, these two connecting wires tend to terminate quite close to one another (perhaps with the same 2-pin pluggable connector). If you or your installer fray wires - or they fray over time due to loosening screw termination - you can end up with a short.

- Poor sensor design can internally short-circuit. Maybe your sensor wires are clean and separated all the way into your sensor box. Eventually, the sensor's circuit board brings the two sides together into the voltage-measurement circuit. If something goes wrong there, the sensor can inadvertently connect the battery's positive and negative terminals.

- Moisture can bridge wires that are otherwise separated. This one is pretty rare, and you likely have bigger problems than just battery damage, but water can be a trigger for short circuits. Imagine a small roof leak that drips in just the right place. It won't take much to bridge two pins on a small connector.

What are the dangers of short-circuited UPS batteries?

Once your battery is shorted, a variety of very bad things can happen - either quickly or much later:

- Temperature can rise rapidly, causing a fire. Your battery's internal temperature might skyrocket, creating a fire that can gobble up the rest of the string and your expensive site equipment.

- Explosive hydrogen can slowly leak and build up in your building. This is perhaps the scariest prospect. If hydrogen accumulates in your small building or enclosure, it's just waiting for a spark. That can be from a random piece of equipment at a random time, or it can be a person visiting the site in a horrific backdraft-style scenario. I recently received photos from a client whose site door was launched several hundred feet through the air after a hydrogen explosion. Fortunately, no crews or residents were harmed. The photos were unbelievable. Needless to say, hydrogen sensors made it into the next budget. We're also proposing our battery monitoring system that offers protection against short-circuiting.

- Your site can fail, creating a service outage. On top of direct damage, don't ignore the impact that a failed site has on your service and reputation. Whether you're a phone company, an ISP, a power utility, or a police/fire radio agency, outages have real-world consequences.

So, with the scary stuff out in the open, what can we do to avoid all of this trouble and danger?

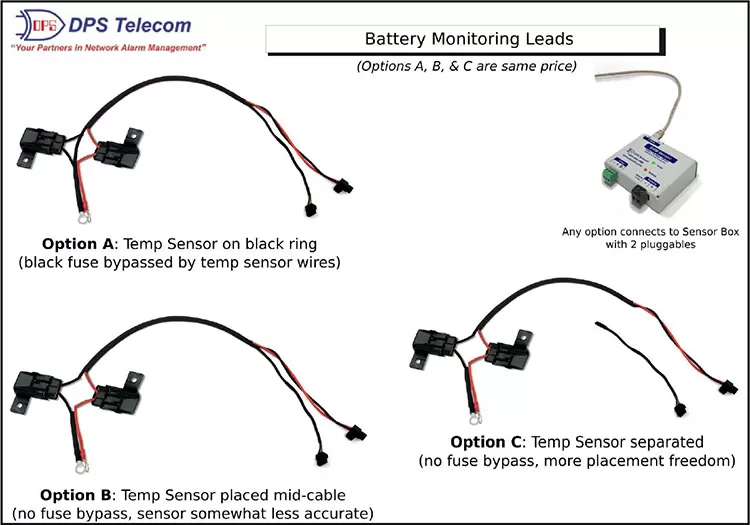

These 3 options from a recent DPS proposal demonstrate the risk-reward balance inherent in battery monitoring. I gave my client 3 options (among even more that are conceivable) that balance performance and the small risk of a battery failure, fire, or explosion.

Battery Sensor Designs that Prevent Short Circuits

Note: There's alway a give and take in risk reduction. Some of the design advice I'll give you here comes at a cost to functionality or purchase price. I'll explain those as we go. You'll have to decide which ones are worth the cost for you. - Internal protection within your sensor. This should be first on your list. An obvious and minimally expensive part is a resettable "PTC fuse". This simple component responds to a short condition - and the associated heat increase - by increasing its resistance. This quickly squelches a short circuit. When the component cools again, normal functionality is restored.

- Sensor protection via replaceable fuses. It shouldn't be necessary if your sensor contains a PTC fuse as noted above, but some people feel more comfortable with the no-nonsense functionality of replaceable fuses. In one of our battery sensors, we used standard automotive fuses (they cost less than a dollar each to replace when blown). There are two fuse slots: one for the positive battery lead, the other for the negative.

- Replaceable fuses near the battery post rings. Beyond internal protection, you can invest further in protection that will endure frayed wires or limited moisture bridging. If you have fuses near your battery post rings, the only way to short the two battery terminals is using the small portions of wire between the post rings and the fuses.

- Temperature and other sensors that follow these same safety rules. Of course, your battery leads aren't the only conductors that pose a risk. Although it's less likely, the metal wires involved in temperature sensing (commonly 3 of them for an analog sensor) can short a battery if somehow damaged. That's why we offer multiple wiring harnesses for battery sensors. If you want the ultimate in temperature accuracy, the small temperature probe and its 3 wires can run all the way down to the black terminal ring. If you're very sensitive to the risk of short-circuiting, we can keep the temperature sensor above the fuses so they don't even come close to your battery terminals. Sensor accuracy takes a moderate hit, but it still does alright. As I said, it's all about trade-offs.

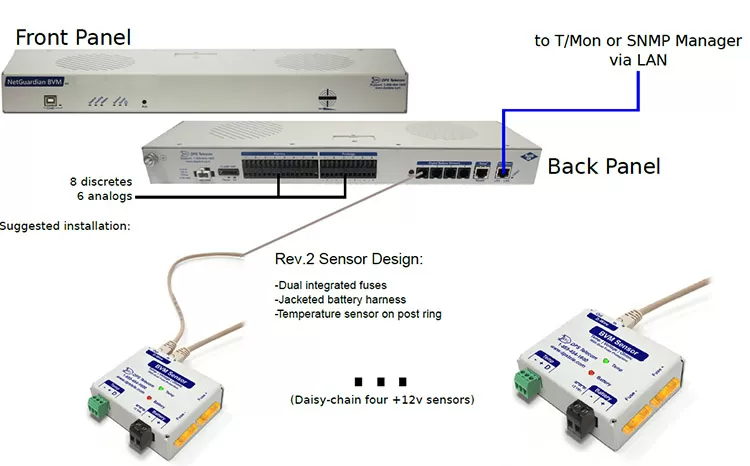

These BVM G3 sensors use a convenient, clean wiring harness that contains temperature sensing on one post ring. To reduce the risk of a short, two automotive fuses are installed into dedicated slots. There's also a PTC fuse component on the circuit board.

Talk to an expert about your remote site UPS battery monitoring

As you can see, there's a lot to think about when planning remote battery monitoring. We've been in the remote site monitoring space for 35 years, and we still learn new ways to edge toward perfection.

I consider it my primary function to facilitate communication between DPS clients big and small. Rare things don't happen at all to many people, but having a lot of contacts makes me aware of small things that have big consequences. You might not always agree with the risk-reward balancing of other clients, but I can at least help you make decisions with your eyes open.

If you value your remote-site batteries, the benefits your business delivers to society, and the health and safety of your workers, good battery monitoring is critically important. While you're at it, you can monitor many other things remotely to improve your service reliability. After all, if you have batteries, you likely have generator tanks to monitor. You certainly have

You don't need to know everything to get started:

Give me (or another DPS expert) a call at 559-454-1600 or email me at sales@dpstele.com

We'll walk you through the process of evaluating your sites, then custom-tailor a monitoring system that suits your requirements and fits within your budget.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...