Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayFailure to start is one of the most serious avoidable causes of diesel generator malfunction. Usually, over 80% of failures to start are caused by battery problems.

Genset owners invest a lot of money to acquire and maintain their generators. But, the Achilles heel of these large, expensive equipment is that their technology hardly evolved since its invention in the late 1800s. This means that most of today's Gensets don't include the capability of detecting that the starting battery has deteriorated and may not be fit to start the engine.

Short for "Generator Set", Genset is a portable power source that utilizes a motor to generator electricity. Gasoline and diesel generator are two of the most common types of Gensets.

If your company's mission-critical network depends on a Genset to be up and running at all times, a failure can mean large economic losses - and, in some cases, even loss of life.

There's a practical, cost-effective solution for this problem: a battery failure detection system. If deployed, this system can help you reduce the number of Genset start failures and associated business risks.

Even though there has been advances in nearly every aspect of standby and emergency diesel generator performance, failure to start continues to be biggest avoidable cause of genset failures. This is an issue because the generator set is an "insurance" that protects your network against power outages.

Like most insurances policies, users expect it to deliver, without excuses and as promised, when needed. Because of that, investments in gensets are very important and even critical.

Weak or undercharged starting batteries are the most common cause of standby power system failures. Even when kept fully charged and maintained, lead-acid batteries are subject to deterioration over time.

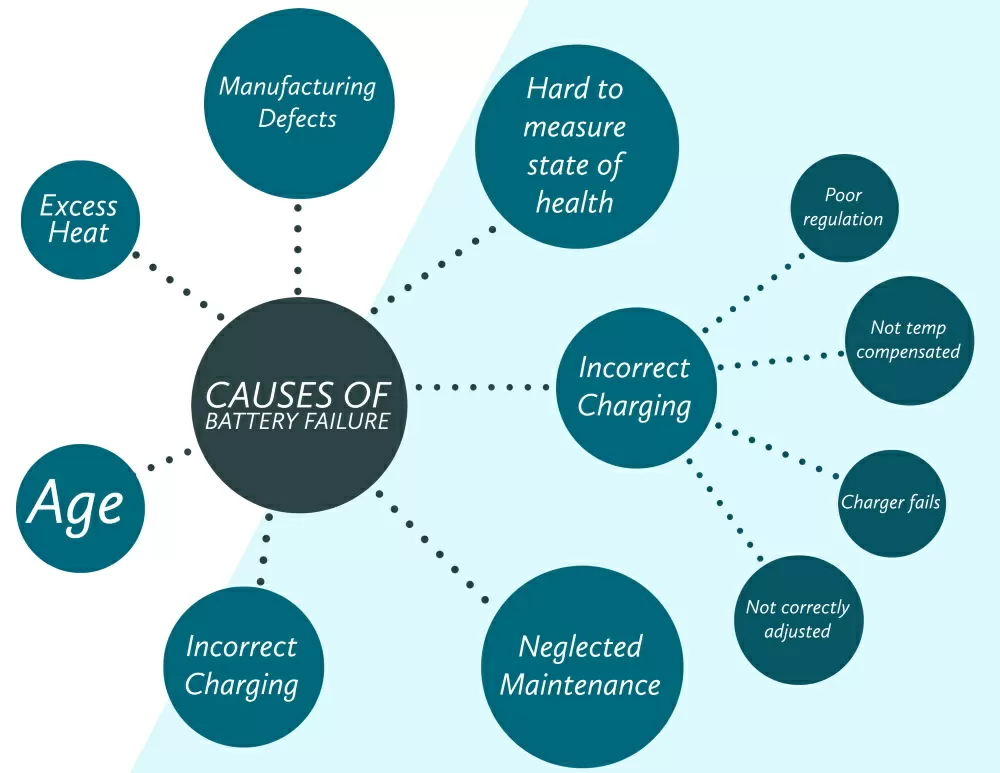

There are many reasons why a battery fails, and here are some of them:

Companies continue to use lead-acid batteries mostly because of its purchase is low compared to other alternatives.

Regardless of what causes battery failure, companies that own generators do benefit from an automated system that is able to assess the health of starting batteries. These systems alert you and your team that batteries have weakened and should be replaced well before they fail to start the Genset.

Most organizations that require network uptime at all times depend on automated remote monitoring systems to reduce battery failures. Multiple data centers, for example, spend tens of thousands of dollars for battery monitoring equipment designed to predict whether their UPS batteries will work. Data centers with downtime costs of six figures per minute often make large investments in battery monitoring devices that can provide early warning of weak battery cells.

If your network also depends on batteries to prevent outages, then you need battery monitoring technology. The best ones will be cost-effective, simple, functional, and easy for existing personnel to use. The following chart summarizes some main points that you need to keep in mind when shopping for your battery monitoring device:

Your battery monitoring device should also contain accurate voltage measurement capability, an alarm reporting system, and means to record information for later analysis.

At DPS, we've designed a cost-effective solution that can adapt to your network and thoroughly monitor your batteries. The BVM G3 is a small RTU built to monitor your battery health. With it, you can monitor battery jar voltages, temperatures, and internal resistance so you can have complete monitoring visibility over your backup batteries.

The BVM G3 has all the necessary capabilities to deliver efficient battery visibility, such as:

Failure to start continues to be the number one avoidable cause of diesel generator failures. The best way to prevent this issue is to deploy an automated battery monitoring system that can detect battery problems before they evolve into bigger issues.

Having a warning time is critical to proactively replace batteries based on real data, rather than solely using the rule of thumb. As a trusted remote monitoring systems provider, we've designed and built the BVM G3 - a competent battery monitoring device that will allow you to avoid all the causes of battery failures that can affect your Genset.

To know about the BVM G3, just send us a quick message.

Morgana Siggins

Morgana Siggins is a marketing writer, content creator, and documentation specialist at DPS Telecom. She has created over 200 blog articles and videos sharing her years of experience in the remote monitoring industry.