Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayIn a power outage, your generators are what keep your systems online and your equipment up and running.

But, how do you know that your generators will work exactly as you need them to when you need them the most?

As an experienced network monitoring solutions provider, we know that good monitoring the answer for that. However, it's important that you make sure your monitoring system can get the job done.

Quite often, we have organizations reaching out to us for a new system, after their basic monitoring system sent them cryptic alarm messages - failing to provide essential information needed to avoid problems or quickly diagnose them.

In order to avoid being spending budget dollars with a generator monitoring system that doesn't give you the promised visibility, it's important to know what to look for and the monitoring best practices.

So, let's get started.

When you experience problems with your generator, did you ever catch yourself wondering "Is it a leak?", "Is it a gauge problem?"

When you monitor a generator you need to have the best visibility possible. After all, how do you know how to fix a problem if you don't know what the problem is?

The following three events need to be monitored to ensure proper operation at your generator units.

You need an alarm that will report whenever the generator is running.

Why is this alarm important? If you see your generator kick on, you'll know you have a commercial power failure (or your battery plant is running empty and the generator has reacted). Most companies and network managers have experienced a network outage because nobody knew the generator was running, until it ran out of fuel, causing the power failure. The end result was the site still went down, the only difference is that it went down later and consumed lots of fuel.

Under normal circumstances, this alarm would be used to make sure your self-tests (manual/automatic) are working correctly. It can also be used as a rough indicator of how long the generator had been running so you can estimate fuel levels and better plan fuel runs.

Pro Tip: Basic RTUs only tell you the generator is on. A superior RTU, like the DPS NetGuardian, allows you to use "derived alarms" (logic formulas). You can program the NetGuardian to ignore the first 15 minutes of running (routine self-test) and only page you if the generator runs longer than 20 minutes (indicating a likely commercial power failure).

Lastly, whenever an unplanned generator running alarm occurs, it gives you plenty of time to initiate the corrective action notifications to the commercial power company.

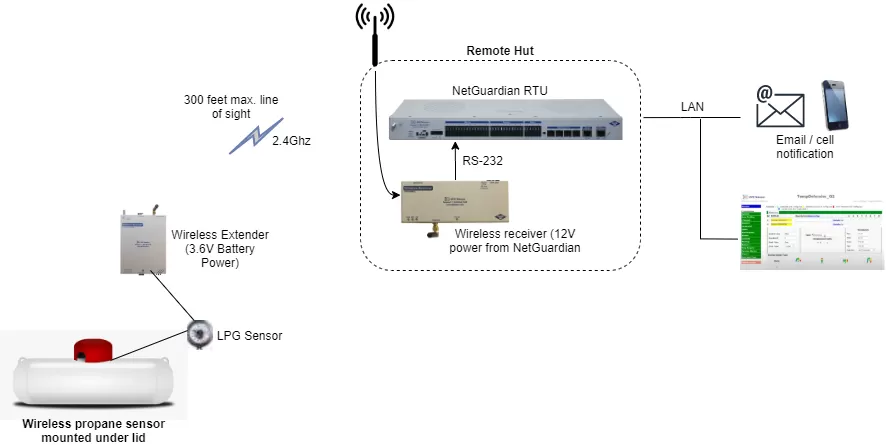

Most modern generators give you the ability to observe how much fuel (usually diesel or propane/LPG) you have in the tank.

However, the low fuel alarm is the lowest common denominator with respect to fuel levels. When the generator sensor detects that it has low fuel, it will report this alarm. Generally, when you see these alarms, you want to act real fast. Depending on your windshield time to your site, and your low threshold warning level, it might already be too late to avoid downtime.

In cases where you have seasonal site access or have to fly in fuel, you have to have a very high level of fuel level awareness.

Another good practice is to have an alarm that will alert when the oil pressure is low. Remember: oil protects moving parts. Without oil you will have a generator that will need some very expensive repairs or your generator will simply shut off (taking down your site with it).

Finally, you want to know that your generator is outputting the right voltage.

Just like any power source, you need to know that you're within the voltage ranges accepted by all connected devices. If the voltage starts to move outside this window, you need to react quickly by performing fast generator maintenance.

The previous generator monitoring best practices can't efficiently be put into practice if you don't have competent monitoring system equipment.

Generators are a critical part of any reliable telecom network design. They are typically the third rung in a power systems ladder. Commercial power, of course, is the primary source for normal operation, followed by your battery and standby generators.

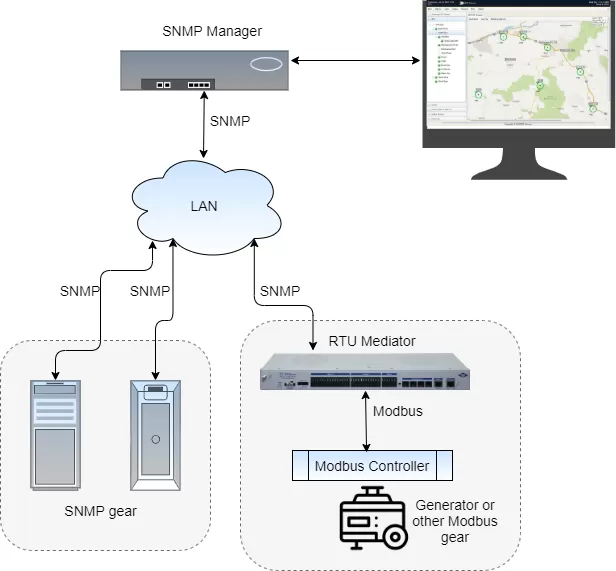

As you may know, generators vary largely not only in size, shape, and power output but also in the technology they use to report alarms. Older generation equipment and basic models use relays to report alarms. These generators require a remote telemetry unit (RTU), such as the NetGuardian 832A, to bridge the gap. The NetGuardian captures these legacy contact closures and converts them into modern SNMP traps that your central master station can understand, extending the life of your existing infrastructure.

Newer models use higher-level protocols, usually Simple Network Management Protocol (SNMP) to provide more detailed status and alarm information. These alarms can be directly monitored by an existing alarm master or Network Operations Center (NOC).

Newer generators may also come with their own generator monitoring system software. This software should not replace a central alarm master, though.

The first step when monitoring your generator is to make sure you have a competent RTU. The RTU will gather your sensors' data and report back to you. So, it's vital that you have an efficient device that does follow the industry's best practices.

Many propane/diesel generators use Modbus controllers. If you don't have a master station that supports Modbus, you need a way to interface with both devices.

When you invest in an RTU that has multiprotocol support, it can be the bridge between your generator and master station. Also, you'd be able to monitor any other Modbus device and other protocols with one single RTU box.

Text messages and email alerts let your network technicians respond to alarms while they're still in the remote site, speeding repairs and reducing windshield time. Look for an RTU that can send detailed alarm notifications to any type of device you prefer.

Also, these notifications should include detailed diagnostic information in each alarm. This way, system operators - without extra training - will precisely what to do and who to call if an alarm happens.

What happens when your alarm management system constantly bombards your staff with status events and non-alarms about your generator that require no action other than an acknowledgment?

Your staff becomes desensitized to alarm reports, and they start to believe that all alarms are nonessential alarms. Your personnel might stop responding to any alarm - even critical ones - defeating the function of the monitoring system.

These self-defeating, nonproductive alarms are called nuisance alarms, and they can have devastating effects. An advanced RTU will have features that filter out nuisance alarms, so your staff can stay focused on preventing serious threats to your network.

It's important that your RTU supports analog trending and graphing.

Trending is a massive help for multiple reasons, it ultimately makes the invisible become painfully obvious.

Some monitoring devices have analog trending capabilities built into their web interface. If your RTU has this feature, then you're ahead of the game. The next step is utilizing them to understand your analogs and overall network health.

Looking at raw analog trend data is a good first step, but it is still easy to miss something. Using graphs to visually represent analog data can make trends and potential problems stand out like a sore thumb.

Once you have a graph, some devices also allow you to export history as CSV. You can use Excel to create a report, or import the data into an SQL server for further analysis or raw queries with the tool of your choice.

RTUs are a great option when handling a handful of devices. However, once you start trying to monitor 10 or more devices, you might want to consider a centralized master that is better equipped to handle the load.

If that your scenario, then there are some best practices you need to pay attention to in order to choose the best master station for your needs.

Just like an RTU, your master station should be able to support any protocol you have in your network.

Once your network alarms are imported to your master, they all should be equal. This means that any alarm should appear on your master interface, and you can set up automatic alerts for your legacy alarms just as easily as for your non-legacy alarms.

This way you won't need to have specialized consoles and you can monitor everything in your network from one screen.

Most likely all your network technicians know how to use a web browser. A web interface makes sure all your techs can access your alarm master, from any computer from any location.

Your web interface needs to be user-friendly and intuitive though. Make sure you can see alarms visually on layered geographic maps, so you can drill down from regions to cities, to sites, to photographs of individual equipment racks. This provides a "war room" view of your alarms right down to the network devices themselves, rapidly accelerating repair operations.

It's also important to be able to get real-time alarms without having to sync databases, nor having compatible software versions, or changing maps.

An excellent master station best practice is to make sure it has good security standards.

Your master station interface should protect your alarms from unauthorized viewing or modification at the user level. A user profile should be required to login to the web browser interface.

Ensure that each user can have different rights to access or change alarms and databases. These profiles should be stored directly within your master station and send to each workstation, making it easy to change user privileges in just one location. If you are not able to set permissions at the user level, a brand new operator might make a huge mistake accidentally.

Your alarm master is a long-term investment that should last for as long as 10 to 15 years.

You need an alarm master system that will support your future growth for up to 15 years. In that time your network is most likely to grow in size, you're going to add new kinds of equipment, and you're going to need new alarm monitoring capabilities. It's important to make sure your future alarm master can grow with your network.

The most advanced alarms masters support around 9,999 devices and 999,999 alarm points.

When you follow the industry best practices you end up with a more efficient generator monitoring system. During power outages, you can have a more controlled response, due to continuous monitoring. You also can get rid of site visits to check level or to fill tanks that are still well above refill level.

In a nutshell, you'll save time, reduce costs and prevent network downtime. A win/win for you and the customers that depend on your service.

Now that you know the best practices involved with monitoring your generator, take the next step and learn how to avoid other causes of wasted site visits.

As a remote monitoring provider, one of our main goals is to help you avoid hidden expenses that will eat away your profits. One of the major expenses of operating a network of remote equipment is windshield time - the time techs spend traveling to and from remote sites.

So, we've created the 12 Leading Causes of Windshield Time and How You Can Avoid Them white paper. Download your free copy and learn how you can avoid wasting money and time.

Morgana Siggins

Morgana Siggins is a marketing writer, content creator, and documentation specialist at DPS Telecom. She has created over 200 blog articles and videos sharing her years of experience in the remote monitoring industry.