Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayYour UPS backup batteries require special care.

If you're treating your batteries like "install-and-ignore" equipment, you're not alone - but you're definitely exposing yourself to risk.

VRLA battery strings are marketed for long life, but many will fail in half the promised time. They die early, they fail silently, and they can cost you hundreds of thousands when they go down. They may only cost a few thousand dollars, but they support your revenue-generating uptime and protect you from SLA penalties.

Maybe you still rely on a schedule that made sense 30 years ago: quarterly visual inspections, maybe a yearly load test, and the hope that redundancy will save the day.

But let's be honest: Hope isn't a strategy.

This approach doesn't align with the reality of how batteries degrade - or how high-energy sites operate. Between site growth, hotter environments, and leaner teams, those old programs are practically designed to miss early warning signs. While customers and users were a bit more forgiving a few decades ago, they now expect perfection.

Let's walk through your six biggest gaps.

Technicians "pop the cabinet" every few months, jot down float voltage, and look for obvious signs of swelling or leaking. But here's what they don't see: plate sulfation, electrolyte dry-out, and internal resistance increases that signal deeper issues.

One maintenance study revealed that visual inspections miss up to 70% of early-stage cell defects. And it shows in the field. Batteries that should last 12-20 years often fail in 5-8 - especially in harsh outdoor environments.

You may think you're maintaining your batteries, when you're just watching them fail slowly.

IEEE 1188 recommends monthly readings and semi-annual performance tests for VRLA batteries. But most operators only perform full capacity tests once a year - or skip them entirely. This happens because those tests require load banks, downtime, and coordination that feels disruptive.

Even basic internal resistance trending - one of the earliest predictors of cell failure - goes unlogged under manual inspection programs.

If your float voltage drifts even 0.1 volts per cell too low, your battery capacity can drop by double-digit percentages. Unfortunately, this can happen without you even knowing.

Ignoring guidelines means you're walking into risk with your eyes closed.

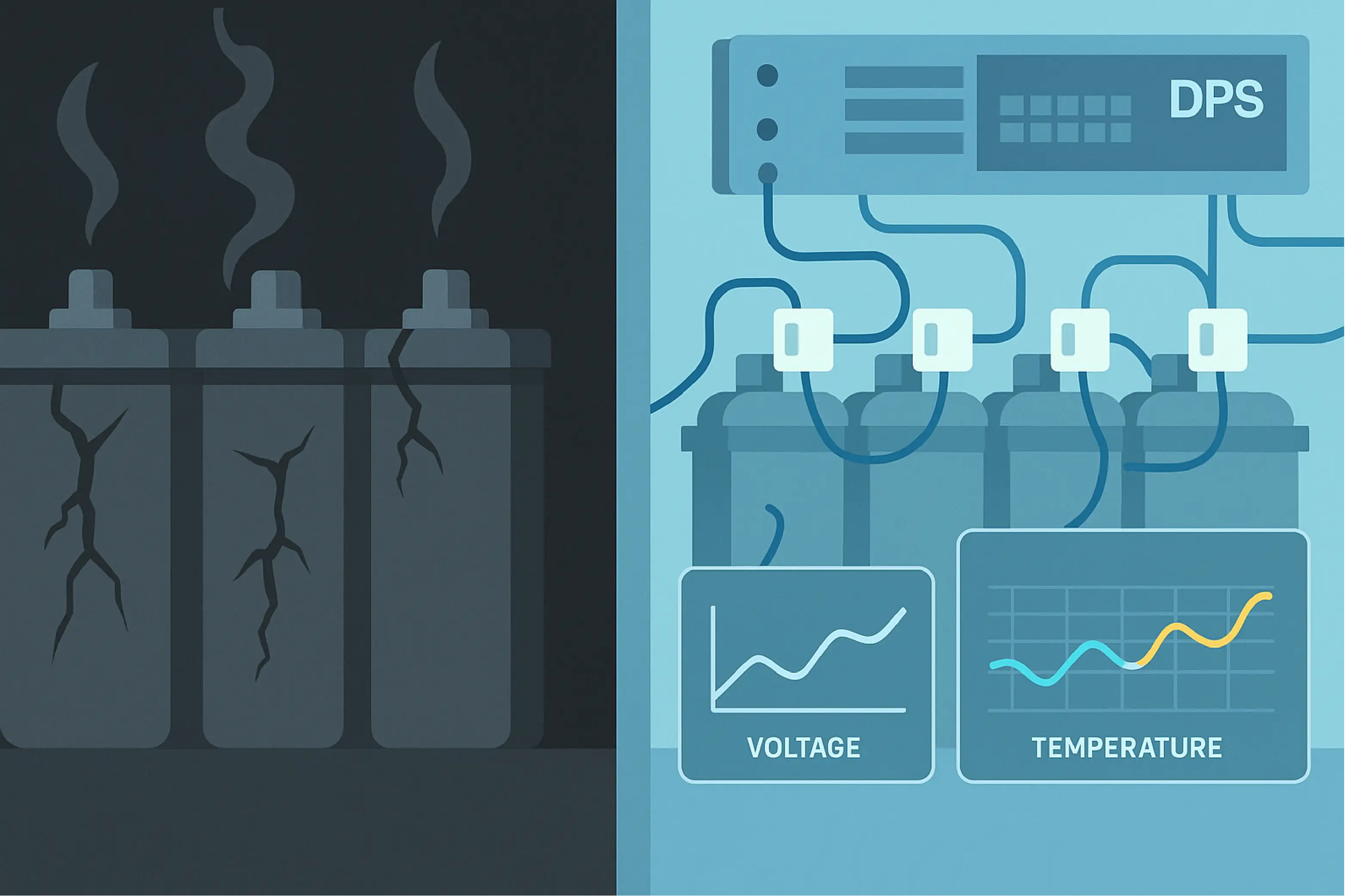

Thermal runaway doesn't start as a disaster. It starts small - maybe with a heat spike or unusual off-gassing. In fact, 85% of recorded thermal events in 2023 showed clear warnings before full failure.

But at unmanned sites, how would you know?

Without real-time sensors on each cell, you never see the warning. And once things escalate to visible smoke, it's already too late. The fire has begun. The cabinet is compromised.

You're not just replacing batteries. You're dealing with safety hazards, site outages, and possible regulatory fallout.

This is happening right now, across many industries with remote telecom sites and UPS batteries.

Every time you send a tech to a site, it costs about $600-$1,000. That's not just fuel and labor. It's the opportunity cost of that person not working on higher-priority projects.

Now multiply that by hundreds or thousands of sites. Truck-roll OPEX can easily exceed your battery equipment CAPEX. Some industry reports call truck rolls the single most significant cost in telecom tower maintenance.

And worst of all, you're spending all that money for data that might already be too late to act on.

Unplanned downtime costs large telecoms roughly $400,000 per hour, according to recent industry reports. Even with backup power and site redundancy, the weakest link is often the battery - because it's the only subsystem not monitored in real time.

Uptime Institute's latest report shows that battery and UPS systems are the #1 cause of major outages. And it's not just theory. NASA, NIH, and other critical facility operators flag batteries as the most expensive single point of failure in their infrastructure.

If your battery fails quietly, you'll learn about it loudly when everything else finally goes offline as well.

You can't build predictive analytics with four data points per year. Yet that's exactly what legacy programs try to do.

Without daily (or even hourly) data on voltage, temperature, and internal resistance, the algorithms that extend battery life or forecast failures simply don't work.

Predictive maintenance has been proven to extend battery life by 30-50% and cut surprise outages nearly in half. But you need a data stream to get there.

Now imagine a better alternative:

You know the status of every jar, every minute. Resistance trends tell you which cells are weakening - long before voltage drops. If temperatures spike or off-gassing starts, you get an alert in real time.

And instead of sending a tech just to gather data, you send them only when something needs fixing. Even better, you replace the specific jar that's failing - instead of an entire bank.

As a result, you have:

That may be the dream, but it's not a fantasy. DPS has already built the system that makes it real.

At DPS, we're not new to monitoring. We've been solving these problems in telecom, utilities, and transit for decades. Our solution to battery blind spots is a purpose-built system that delivers real-time, per-cell monitoring - without requiring new infrastructure or complex installs.

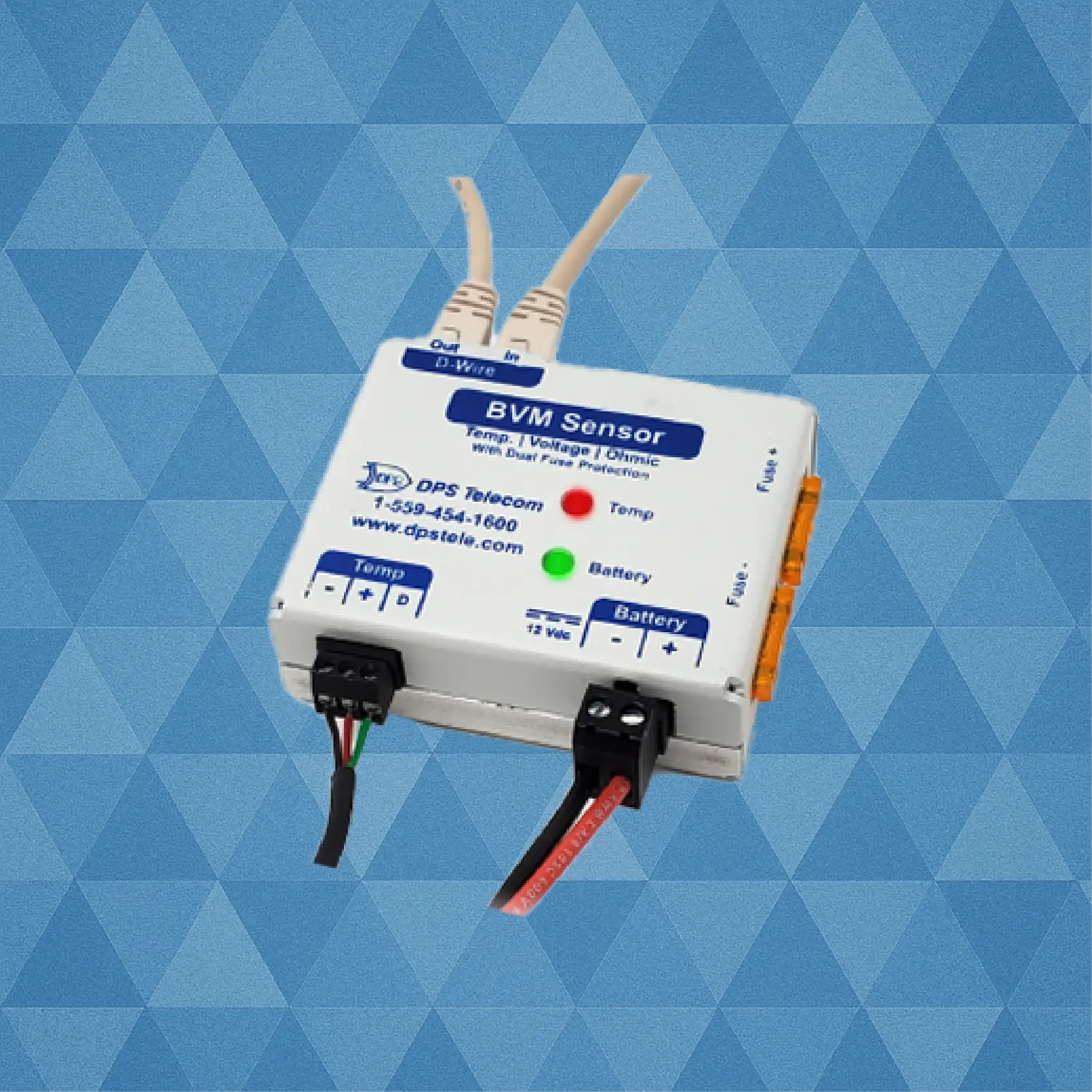

Each BVM sensor tracks voltage, internal resistance, and temperature for a single battery jar. And it does all of this over a single RJ11 cable that shares both power and data. There are no external power bricks or extra wires.

Sensors daisy-chain to cover up to 48 cells, running up to 600 feet back to the RTU.

A G6 832A NetGuardian is more than just an aggregator. It's a complete remote monitoring platform with:

It applies intelligent thresholds, stores 32-day resistance and voltage trends, and sends alerts through SNMP or HTTPS. Plus, these RTUs can integrate with T/Mon, Progress Rail, or any modern NMS.

And since the logic runs locally, alarms still get logged even if your network backhaul fails. Any automatic responses will also continue during a backhaul failure.

The best part of the solution is it's a plug-and-play upgrade to your existing DPS environment. This means no additional IPs to manage and no firewall nightmares. Finally, the same RTU that monitors your doors, HVAC, and generators now brings your batteries into view.

Adding value, the system can visualize data in real time, right on the device or remotely through your central dashboard. Predictive alarms warn you when resistance starts to rise - before voltage fails. And for distributed teams, notifications can be sent directly to techs' inboxes or phones, even without a centralized NOC.

This means your team can act faster - and smarter.

Most battery monitoring systems are either overly complicated, IP-intensive, or tied to a specific battery vendor. DPS isn't any of those things.

This is a field-proven platform for telcos, railways, utilities, and government agencies that can't afford surprises.

It's time to stop pretending that quarterly checks and a clipboard are enough.

Your network deserves better - and so does your team. The DPS BVM sensors and NetGuardian G6 platform gives you everything you need to turn your backup batteries from a hidden risk into a visible, manageable asset.

Let's build a better plan together.

Call me at 559-454-1600

Or email sales@dpstele.com

On a video call, I'll walk you through a real example, show you how the tech works, and help you avoid the next big outage before it ever begins.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...