Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayPharmaceutical companies and manufacturers must adhere to strict regulations to ensure product safety and quality. One such regulation is the 21 CFR Part 11, which sets the standards for electronic records and electronic signatures.

Let's explore a recent conversation between a DPS engineer, "JP," and a prospective client to illustrate how DPS Telecom can address complex remote monitoring needs.

Client: Hello, I need sales assistance.

JP: Hello, how can I help?

Client: Can you confirm if this software is used in 21 CFR compliance for pharmaceutical companies?

JP: Checking, one moment. If I understand correctly, the 21 CFR is for electronic document security of sensitive data.

Client: Yes, but we require it only for pharmaceutical production use. Can you customize for that?

JP: Yes, we can customize to the specifications you provide.

Client: This is our requirement.

JP: It appears that this is a QM process to ensure the stickers are affixed properly. Is my understanding correct?

Client: Yes, label for the bottle. Line no 31 or 32 is very important.

JP: The process of scanning labels to ensure they are affixed appropriately is not something we have experience with. We can customize a product that could meet this need, but it would involve a one-time non-recurring engineering fee. In some scenarios, we can offer a discount or possibly waive the fee.

Client: Ok. Also, we need PLC programming with hardware.

JP: We have RTU, not PLC. The RTU can accomplish this process. How many RTUs (PLCs) would be needed for this project?

Client: We need one PLC for online rejection.

JP: If a label is detected to be faulty or misaligned, do you want to send a notification online?

Client: Yes.

JP: Who does the rejection get sent to and what happens when a rejection is detected?

Client: Our cameras.

JP: Your camera is given the rejection notification?

Client: Yes.

JP: When the camera is notified, what does it do?

Client: After rejection detection, it goes to the rejection bin with a pneumatic cylinder. The camera works with control.

JP: Ok, the camera is scanning labels...150 images per minute. If the camera detects over print or detects the wrong dosage on a label, the RTU (PLC) will then latch the actuator to stop the printing process (or kick it to the rejection bin).

Client: Yes.

JP: Ahh, not shut down. It kicks the bottle down a different path to the bin.

Client: Yes, rejection bin.

JP: Do you have a camera already that can scan?

Client: Yes.

JP: I am curious... We can potentially build a customized solution for this. Are there any other vendors that already have the solution developed?

Client: Yes, lots of vendors.

JP: Have you considered them?

Client: In the pharma industry, used for the last 10 years. We need your help on software development for line no 31, 32, or 33.

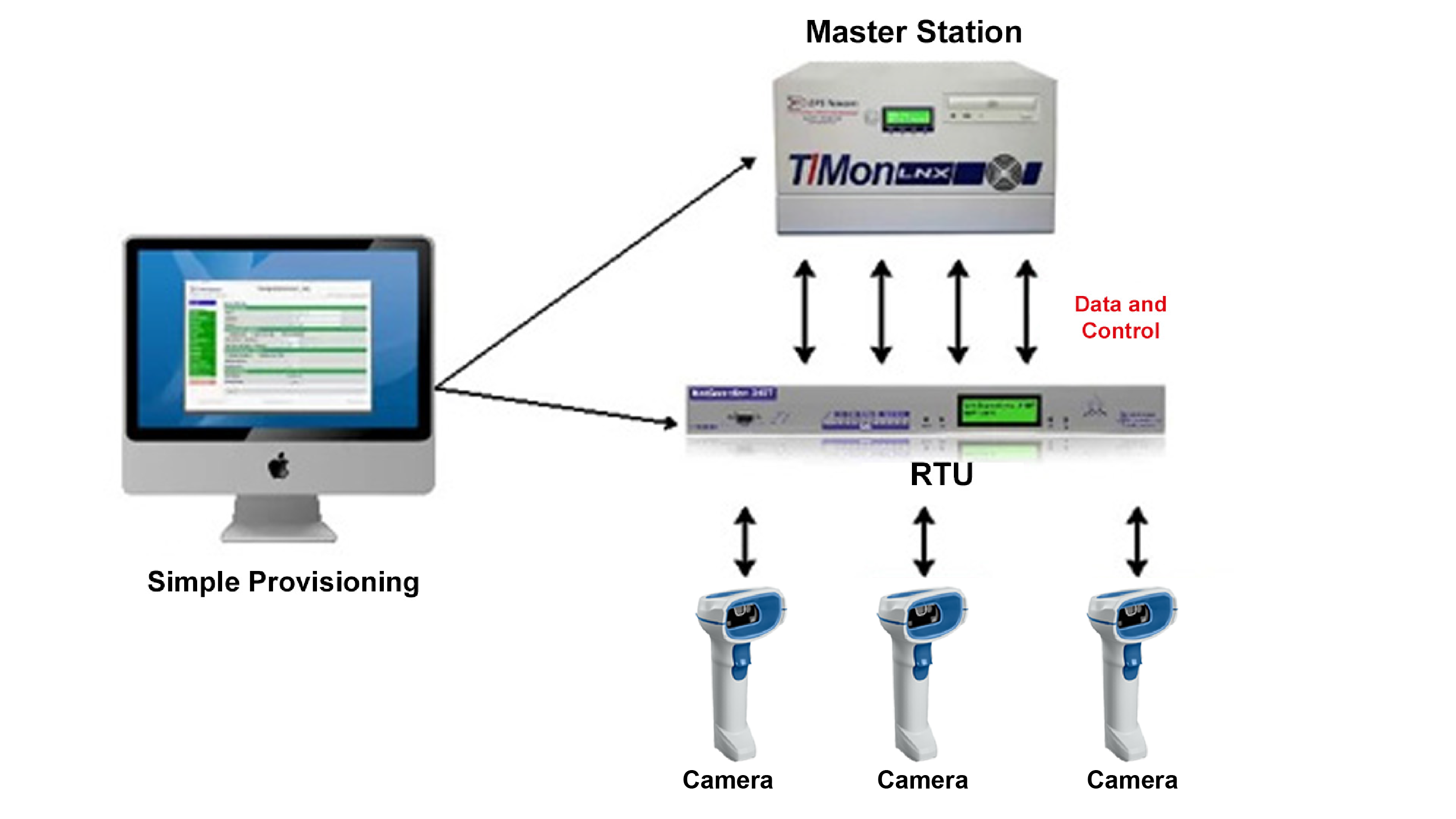

JP: Based on what I see, it could cost a lot to develop. If you have that amount in your budget, I would like to look more deeply and provide you with an actual cost. We would use our T/Mon and customize the software to meet your specs.

Client: 25,000 dollars.

JP: I am thinking it will be more than your $25,000 budget. It could be lower, but I wouldn't know until we get into technical details of the camera software and interface. I could be understanding wrong... You have a camera, and you have a device. You need to accept the output from the camera and store it?

Client: Yes. In India, this type of software costs approximately $260 to $290 USD. With all camera and hardware, a complete set is $2500 USD. 25000 USD. Software cost is $2500 USD. Are you online?

JP: Yes. The hardware server without customized software will start at much higher than those prices.

Client: I am offered all setup for $25000 USD.

JP: That is the amount you are being paid? Or, is that the amount you are offering us to develop?

Client: $2500 USD for development charges in current market prices. As per my requirement, think again on requirement sheets, then quote.

JP: I don't think we will be able to assist you. Any customized software we design would be specifically loaded on our hardware. The hardware with customized development will be more than what you are being offered. The vendors that already have done this will be able to offer you a more competitive price.

Client: Yes. We need only software. We have all hardware.

JP: Yes, the software is specific to our hardware. We would not be able to provide you software to load on your hardware.

Client: Ok, then you will provide complete solutions. Send the proposal to my email.

JP: Do you have any technical information on the camera and what it is connected to? What protocol will be used to send the information to be stored?

Client: Camera from this Illinois supplier, you can check the camera series.

JP: Ok.

The conversation began with the client's inquiry about compliance with 21 CFR Part 11 for their pharmaceutical production line. They needed assurance that the software used in their processes adhered to this regulation. JP quickly confirmed their understanding and moved forward with the discussion:

Client: Can you confirm if this software is used in 21 CFR compliance for pharmaceutical companies?

JP: If I understand correctly, 21 CFR is for electronic document security of sensitive data.

Client: Yes, but we require it only for pharmaceutical production use. Can you customize it for that?

JP: Yes, we can customize to the specifications you provide.

This exchange highlights the flexibility of DPS solutions in adapting to specific needs and requirements. This enhances the reliability of the remote monitoring system and production process.

As the conversation progressed, the client shared detailed requirements. These requirements included the necessity for a process to ensure labels are affixed properly on bottles. They emphasized the importance of specific lines in their production:

Client: This is our requirement.

JP: It appears that this is a QM process to ensure the stickers are affixed properly. Is my understanding correct?

Client: Yes, label for the bottle. Line no 31 or 32 is very important.

JP's response underscores the importance of customization in meeting unique client needs. DPS Telecom is able to tailor solutions to specific production lines and processes. Tailored solutions from DPS ensure that all regulatory and operational requirements are met.

One significant challenge mentioned was the need for a strong scanning and rejection system for labels. The client required integration with their existing camera system. This would allow them to detect faulty or misaligned labels and redirect them to a rejection bin:

JP: Ok, the camera is scanning labels...150 images per minute. If the camera detects over print or detects the wrong dosage on a label, the RTU (PLC) will then latch the actuator to stop the printing process (or kick it to the rejection bin).

Client: Yes.

Real-time monitoring and response are crucial in pharmaceutical production. Delays or errors can lead to significant product quality issues. DPS Telecom's solutions, like the T/Mon monitoring system, are designed to provide immediate alerts and actions. This ensures that production continues smoothly and efficiently.

The client also highlighted the necessity for integrating specific software into their production line. They needed a system that could seamlessly work with their existing equipment:

Client: We need PLC programming with hardware.

JP: We have RTU, not PLC. The RTU can accomplish this process. How many RTU (PLCs) would be needed on this project?

Client: We need one PLC for online rejection.

DPS Telecom's Remote Telemetry Units (RTUs) provide the flexibility needed to replace traditional PLCs. This offers a well-rounded and reliable performance. RTUs can be customized to integrate with various hardware components. This ensures that the entire system functions cohesively.

Seamless integration with existing systems is not a foreign task for the DPS Telecom team. DPS ensures that their solutions transition smoothly and that all their components work together effectively. They do so by customizing solutions to fit the specific requirements of the client's infrastructure.

The client wanted to confirm that the DPS solution could work with their current camera system and other equipment:

JP: Do you have a camera already that can scan?

Client: Yes.

JP: Do you have any technical information on the camera and what it is connected to? What protocol will be used to send the information to be stored?

Client: Camera from this Illinois supplier, you can check the camera series.

DPS Telecom makes sure to thoroughly understand clients' technical environment and requirements. This confirms that we can meet the client's needs and provide the solution for which they are looking. This also makes sure clients' solutions are incredibly specific and integrate seamlessly with their existing infrastructure.

This specific client was seeking our software integrated with their existing hardware, specifically their cameras. JP made it clear to the client that our software is specific to our hardware and could not be applied to their existing technologies. No matter how much we can provide, we are fully prepared to set you up for success in any way that we can.

JP further explored the client's existing infrastructure and potential budget constraints, providing transparent communication about the costs and capabilities of DPS solutions:

JP: If you have that amount in your budget, I would like to look more deeply and provide you with an actual cost. We would use our T/Mon and customize the software to meet your specs.

JP's honesty about costs and potential challenges exemplifies DPS Telecom's commitment to providing realistic and effective solutions. Despite a difference in budget expectations, JP ensured the client understood the value and capabilities of the proposed customized solutions.

Even though our solutions were slightly different than desired, we still make it our goal to provide tailored solutions in any way that we can. In this case, the client was limited by their budget. However, they still asked to be quoted for their proposed solution. Regardless of the whether require our products or not, DPS is ready to answer your questions and help you optimize your operations.

As the conversation drew to a close, JP aimed to finalize the details and prepare a formal proposal. This included understanding the client's full requirements and making sure that all technical aspects were covered in the quote.

DPS makes it their goal to thoroughly understand all of the technical specifications and requirements of our clients. The team can craft a proposal that addresses all aspects of your project, just as we have done here. This will guarantee that your solution is both comprehensive and tailored to your needs.

This conversation illustrates DPS Telecom's commitment to providing tailored solutions for clients, including those in pharmaceutical production. DPS carefully takes client needs into consideration to create a solution that supports strict regulatory requirements.

Our staff is focused on customization, transparency, and technical expertise. This means they are well-equipped to help your company enhance your operations.

For tailored solutions that integrate seamlessly with your existing systems, or to ask a question, reach out today!

Call 1-800-693-0351 or email sales@dpstele.com.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...