Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayIf you have a Generac generator, you have to monitor it. Because it's a combustion engine, it has many subsystems that affect performance.

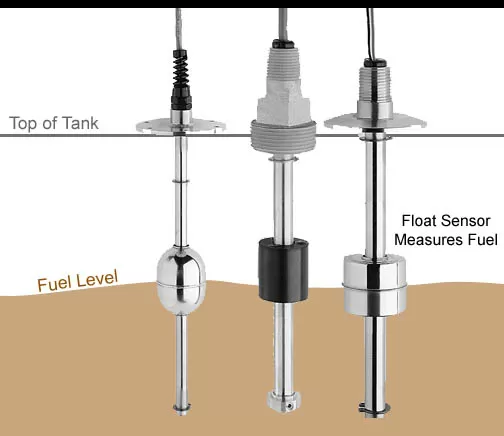

There's obviously a fuel tank that must be monitored, but also other items like pressures and oil temperature.

You can't afford to ignore any generator, because it's mission-critical backup power for your building.

So, how do you go about monitoring your generator, particularly a Generac model?

Generac's remote monitoring system is a great way to keep track of your generator's performance without being on-site. According to Generac:

Mobile Link Industrial is a remote generator service that adds an extra layer of protection through remote monitoring. It relays pertinent generator information directly to your service distributor 24/7. This enables improved generator operations, increases generator uptime, and improves service response time.

As you can see from that description, the system is an excellent way to avoid downtime when you have generators at an otherwise manned location.

MODBUS protocol is a common link between generators and your overall remote monitoring system

If you manage remote sites, such as those used for telecom purposes, your generator is just one of many things you need to monitor.

In this case, dedicated generator monitoring won't cover 100% of what you need.

In all likelihood, you'll have generalized remote monitoring devices like RTUs to cover monitoring of site temperature, humidity, door openings, equipment failures, and other important events.

For this reason, you'll want to use a remote monitoring system that can connect to your Generac generator via the MODBUS protocol. This assumes, of course, that you choose a Generac generator that supports MODBUS. Fortunately, many do. Just be sure to select this option when ordering, if that applies to your selected generator model.

If you're not already familiar with MODBUS protocol, be sure to read through the guides I've published here previously.

Older generators may have contact closures instead of MODBUS

If you're dealing with an older generator, it's likely that it uses contact closures for remote monitoring instead of (or in addition to) a protocol like MODBUS.

Because contact closures are hardware, you won't find nearly as many specific alarms. Instead, it's very common to see "summary contacts" that tell you simply whether you have an active Minor, Major, or Critical alarm.

Other than the obvious difference in RTU compatibility, the overall monitoring architecture is identical if you have an older generator. Your RTU will still collect data from your generator, then forward that data to your central alarm monitoring system.

In many ways, cloud technology has been a revolution. There's a tremendous convenience associated with simply routing data from your remote devices, including generators, to a server in the cloud.

Before you dive right into that option, however, you should consult your organization's security policies. Some companies have strict requirements about where data can be stored. They may not allow for cloud storage, particularly if the data includes personally identifiable information (PII). This isn't common in telecom, but general security rules can create the same sorts of problems for you.

In that case, you'll need to investigate on-premises remote monitoring solutions. These systems store data on a central server within your organization's network. That obviously requires more infrastructure on your part, but it may be the only option depending on your company's security posture.

With an on-premises remote monitoring set-up, you'll be responsible for maintaining the central server (or servers) and network infrastructure. That obviously requires in-house IT resources or the use of a third-party vendor. Again, this might simply be the cost of your compliance with your own (or the government's) security regulations.

You have a lot of choices when choosing RTUs and central alarm masters. One thing you should absolutely ask when building your "short list" of purchase candidates is how much experience your vendor has with your exact specifications.

There are several types of acceptable evidence here. First, I have to acknowledge that a generator manufacturer frequently will do a fine job monitoring their own systems. For that reason, a Generac monitoring system can probably work quite well for its intended use.

As I noted above, you must recognize when you're monitoring equipment that goes beyond just your generators. There is clear value in having a single integrated monitoring system vs. several disintegrated systems.

If you do seek a general-purpose third-party monitoring system, ask for specific case studies of customers who have used that monitoring system to monitor Generac generators before.

Oddly enough, at DPS, we act as our own case study for generator monitoring. That's because we have a medium-sized Generac generator behind our HQ building to provide backup power.

Years ago, as we worked on our first major MODBUS-parsing project within a NetGuardian RTU, we used our Generac as a way to confirm we were handling MODBUS registers properly. For reference, our model looks something similar to the Protector 150kW (Model #RG15090).

This pre-release testing was a critical part of development we were doing for a national government, and it made our MODBX product very robust.

Of course, since that time, we've sold NetGuardians to monitor hundreds and hundreds of client generators at remote telecom huts and enclosures.

When you shop for Generac monitoring options, be sure your vendor has a proven solution.

If you're considering remote monitoring for your Generac generators, I encourage you to give me a call. DPS has been in the monitoring business for almost four decades, and I've helped clients with remote monitoring set-ups of all sizes and complexity. We can discuss your needs and find the remote monitoring solution that's right for you.

Remote monitoring for your Generac generator isn't exceedingly difficult. I promise you'll feel much better once we get this problem knocked out together.

Give me a call at 1-800-693-0351 or email me at sales@dpstele.com

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...