Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayI recently finished wrapping up another remote site monitoring proposal. This proposal was for a long-time DPS client.

They're a governmental agency with telecom shelters in very remote locations. Let me give you some insight on how DPS works with clients like you to accomplish your project goals.

Our client was looking to upgrade their HVAC monitoring and control system. Their telecom shelter configurations consisted of:

Each shelter was programmed with some pretty basic logic. The cross-flow system is comprised of exhaust fans and a damper system. When the outdoor temperature was optimal, Economizer Mode would be activated: Dampers would open, cool air would be brought inside (free cooling!).

When indoor sensors detected a rise in temperature: Deactivate Economizer Mode and activate HVAC mechanical cooling. If temperature rises to critical levels, Emergency Mode is activated. It's "all systems on" at this point to cool a site that is severely overheated.

This cooling system worked. It only lacked a few points. There was no method to get notified if the HVAC units were powered on. They could only check the temperature levels in a manual fashion.

Indoor temp fluctuations over a period of time indicated the system was powered on and (hopefully) healthy, but this is a "secondhand" way of monitoring. It doesn't paint the clearest possible picture.

Limited monitoring also created another problem. HVAC systems sometimes lock up and need to be power-cycled (which took extra time to notice because only temperature was being monitored). The only one way to remedy this was to dispatch crews to the site.

As previously stated, the system worked at some level. They could have kept the status quo. But what happens when someone isn't able to notice the temperature fluctuations? Risking damage to critical equipment and (even worse) service interruption is unacceptable.

Our client had very remote locations. High altitude settings and vast distances existed between shelters. Trucks are not always an option. In fact, a helicopter is the only mode of transportation that can reach some of these snowy shelters. Continuing to incur high costs flying crews in to "investigate" and solve simple problems didn't make sense - especially in our age of advanced technology.

Having the ability to truly monitor remotely is fundamental for long-term cost savings. Knowing is the key.

Our client needed true remote monitoring. They couldn't continue relying on best guesses. In order to improve their situation, they need the ability to:

Our client was well aware that solutions existed to improve their situation. Their agency was finally at a point where they could no longer assume the risk of "if it ain't broke, don't fix it". The knew the had to act, so they contacted me in late September 2021.

As with any project, I spoke with this client about what he wanted to accomplish in this project. We had several phone calls, and then I prepared an initial proposal.

Here's a glimpse of what I recommended:

Our proposals contain detailed schematic drawings and product descriptions. After review of the initial proposal, our client has a bigger vision for the project. Capability, compatibility, and scalability were all up for consideration.

Ultimately, a video conference seemed most appropriate for the next meeting with a larger group. We would get together and hash out all the intricate details. Technical folks like to ask technical questions (oddly enough). Benny, one of our engineers here at DPS, provided the responses. At DPS, we frequently involve engineers in pre-sales discussions to make sure everything perfect. After nearly two hours into the video conference, we were all assured that we had the right solution.

After our meetings, the scope of the project was increasing to monitor more things than ever before. As an existing holder of DPS products, our government-agency client had witnessed firsthand the reliability of our devices. This earned us their interest in an additional opportunity.

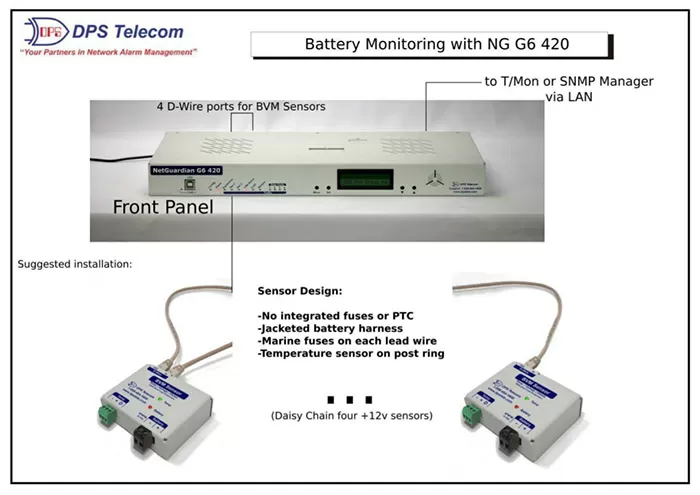

The new business that was up for grabs was the monitoring of their emergency power backup system: A battery array and diesel generator.

DPS doesn't just push our most expensive products on you. We only provide what's necessary. In this case, we worked with our client to identify some new needs, so the equipment allow was justified.

Here are the new additions to the proposal:

We are pleased to be given the opportunity to assist. Our client reciprocated. They have decided to move forward with a three-site pilot by the end of 2021. We look forward to continue to offer our support (and soon, expansion to all 200 of their sites).

At DPS, we have clients - not customers. All of our products are covered by a 30-day money-back guarantee. You can be assured our products will work for you. Assistance is provided at every step.

We take every opportunity to EARN you as a client - today and into the future. See how DPS can help you and your company out. Call us now at 800-693-0351 or email me at sales@dpstele.com

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...