Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayYou probably know that keeping your mission-critical equipment cool is one of the most critical aspects of the overall health and performance of your network. After all, high temperatures inside your facilities can result in a complete thermal shutdown.

If you depend on HVAC units to cool your remote sites, then you're most likely paying an expensive energy bill. But, there are other methods that will help you save energy - which ultimately means saving money.

As a remote monitoring solutions provider, we are experts in these kinds of scenarios. And, we want to make sure you can make informed decisions when it comes to your network, so we'll go over how you can accomplish cooling your remote sites while monitoring them and saving money.

Let's dive in.

Most telecommunications remote sites are affected by problems that need to be taken into consideration to ensure efficiency. Some of them are:

So, in order to have a reliable and "visible" site, you need to be aware of the status of your remote equipment. This way, in case a problem happens, you must be notified immediately about it to be able to respond in a timely manner.

Initially, remote sites were cooled by free-air systems that used outside air to cool the interior and the equipment within. This method, however, was deemed unacceptable due to the dirt, dust, and other debris that were brought into the structure.

The solution was to replace the free-air systems with two HVAC units. The two-unit protocol was put in place so that backup was available in the event of extreme temperatures in the area that the remote sites were located.

With such an intense focus on reliability, visibility, and energy savings, much attention has been turned to finding a solution to cooling issues within remote sites.

Although each point above is able to solve parts of the overall problem, they still leave issues unaccounted for. So, in order to solve the problem as a whole, you need a product that can cool efficiently while monitoring the environment and relaying the information back to network technicians for constant situational awareness.

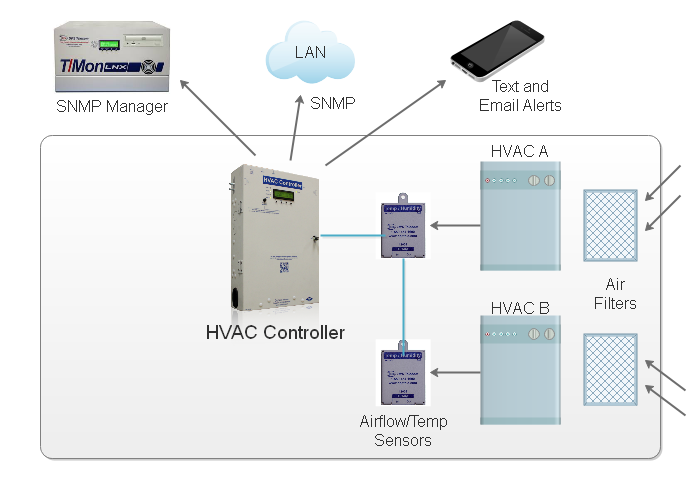

To solve the remote site cooling issue and to gain complete visibility over your HVAC system, the recommended solution is an intelligent high-efficiency, energy-saving fan with a remote monitoring lead-lag controller. This system makes it possible for techs to constantly monitor equipment performance remotely while also being able to make adjustments and take advantage of free outside air.

This results in decreased air conditioning usage by around 50% (averaged across the coolest 77% of US climates). There are a handful of obvious benefits of utilizing an economizer system like this:

As existing remote sites age, this system will allow for cooling operations to be streamlined, and new sites will deploy this new type of economizer HVAC system going forward.

The controller system will allow for lead lag control, as well as monitoring and remote control of the site's environment. It will use data collected by multiple sensors which will measure the following:

All of these points need to be monitored in order for the overall status of the remote site to be relayed. Also, the environmental aspects play a big role in the operation of the economizer system. If the temperature outside is too warm, the high-efficiency fan will not introduce it in to the structure. Instead, one of the AC units will run.

Humidity inside the remote site needs to be monitored as condensation can build up and cause equipment failure. Other aspects are monitored in order to give visibility over the condition of system components.

An intelligent free-air cooling device should be comprised of durable materials to guarantee long life, as well as reliable cooling. The third necessary component is remote monitoring capabilities.

Traditional remote site cooling systems, such as HVAC units, operate by cooling down recirculated air within your structure. There are typically a few disadvantages to using HVAC units to cool spaces, they are:

Your network equipment can go on a complete thermal shutdown when under high temperatures, so it's critical to keep your sites cool. But, how do we do this without using tons of energy and spending a great deal of money?

In order to better understand how an economizer can save you energy and be a worthwhile expenditure, you need to know how it works.

When deployed, the system will collect information from both HVAC units and the high-efficiency fan. It will relay the site's internal and external temperature, humidity, hydrogen levels, static pressure, and detect smoke if it's present.

As the internal temperature rises due to heat output from the gear in the site, cooling becomes necessary. When the outdoor temperature is sufficient (below 78 degrees F, for instance) the system will start the cooling process with the intelligent high-efficiency fan.

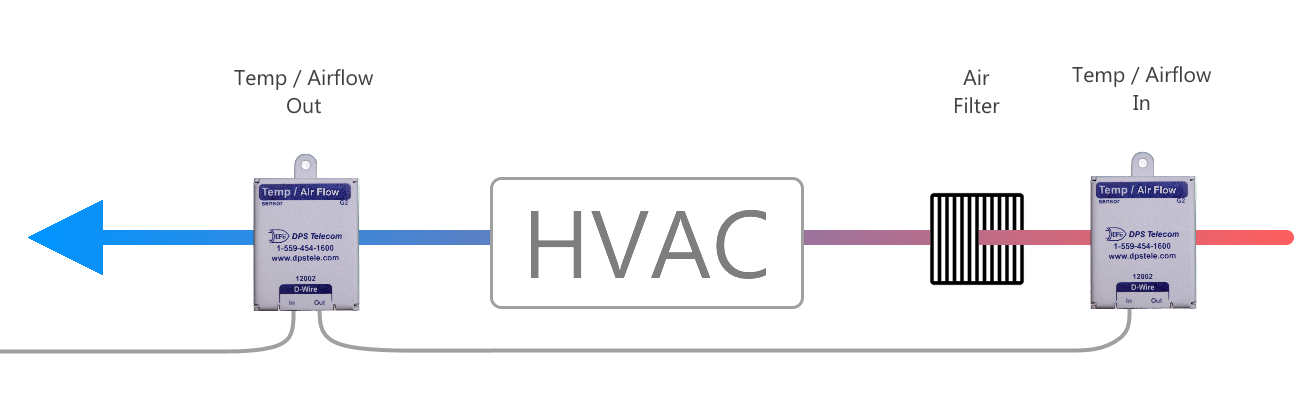

When these elements are conveyed, the system controller will communicate to the fire dampers, telling them to open. Once open the fan will be told to run. It starts at a slow speed, drawing in cool air through a sophisticated filtration system while only using a few watts of energy.

The fan simultaneously blows the warm exhaust outside of the site and away from the equipment. When the fan is in operation, the site's internal and external static pressures are monitored using a pressure differential gauge. This information conveys the status of the filters (if they need to be replaced, or if they are obstructed, etc.).

As the internal temperature of the site is monitored, the controller will automatically adjust the fan speed in order to maintain a precise site temperature of under 78 degrees F. At its maximum speed, the intelligent fan will move 2,000 CFM or air through the site using 150 watts. This makes it four times more efficient than any other free-air fan, and up to twenty times more efficient than a conventional AC unit.

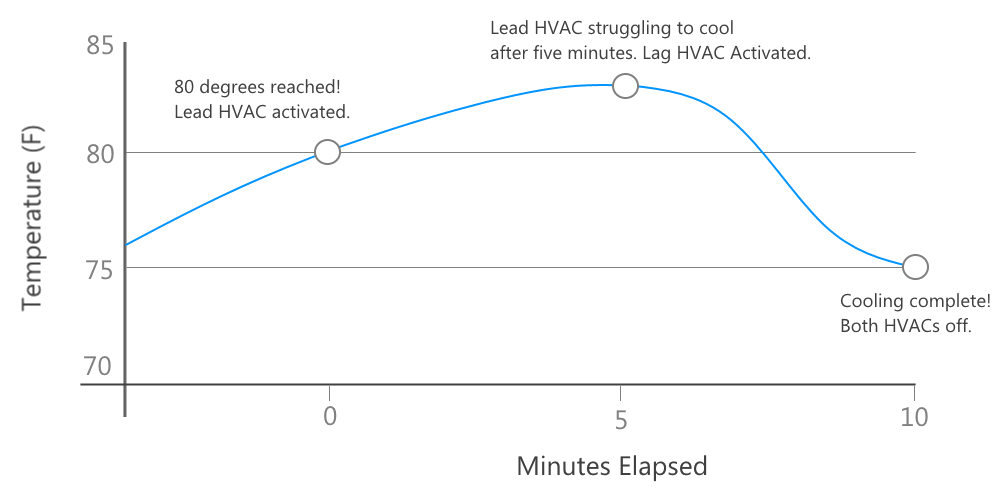

When the external temperature rises and is no longer sufficient for effective cooling with the fan, the controller starts the fan shutdown sequence. The dampers automatically shut after the fan comes to a complete stop, and this alerts AC unit #1 to start running. This process takes about four seconds.

The temperature in the remote site is logged over time by the system controller. If the air conditioning is giving the desired cooling effect for the power consumed, it continues to run. If not, it is stopped and AC unit #2 starts up. In the occasion of neither unit is producing the necessary cooling effect (temperature less than 78 degrees F), the fan will start running again using the sequence described previously.

There are many preferences that you need to pay attention to when looking for your HVAC controller. Some of the most important are:

The obvious benefits of deploying an economizer system are reduction of energy use, increased cooling reliability, the prolonged lifespan of equipment, and of course the ability for network techs to have visibility and remote control of remote sites.

In a nutshell, investing in a temperature monitoring system will give you important ROI results.

But, there are some aspects and details that you need to keep in mind in order to be successful. So, nothing better than getting a tech brief prepared by our engineers about temperature monitoring. In this document, our experts aim to give specific solutions for your temperature monitoring needs. Get your free PDF copy.

Morgana Siggins

Morgana Siggins is a marketing writer, content creator, and documentation specialist at DPS Telecom. She has created over 200 blog articles and videos sharing her years of experience in the remote monitoring industry.