Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayAn important aspect of a remote monitoring system for your network is collecting and reporting information from your sites. Your monitoring system needs a way to collect this data and report it to you in a purposeful way.

Without a data collection, your monitoring system would be completely ineffective.

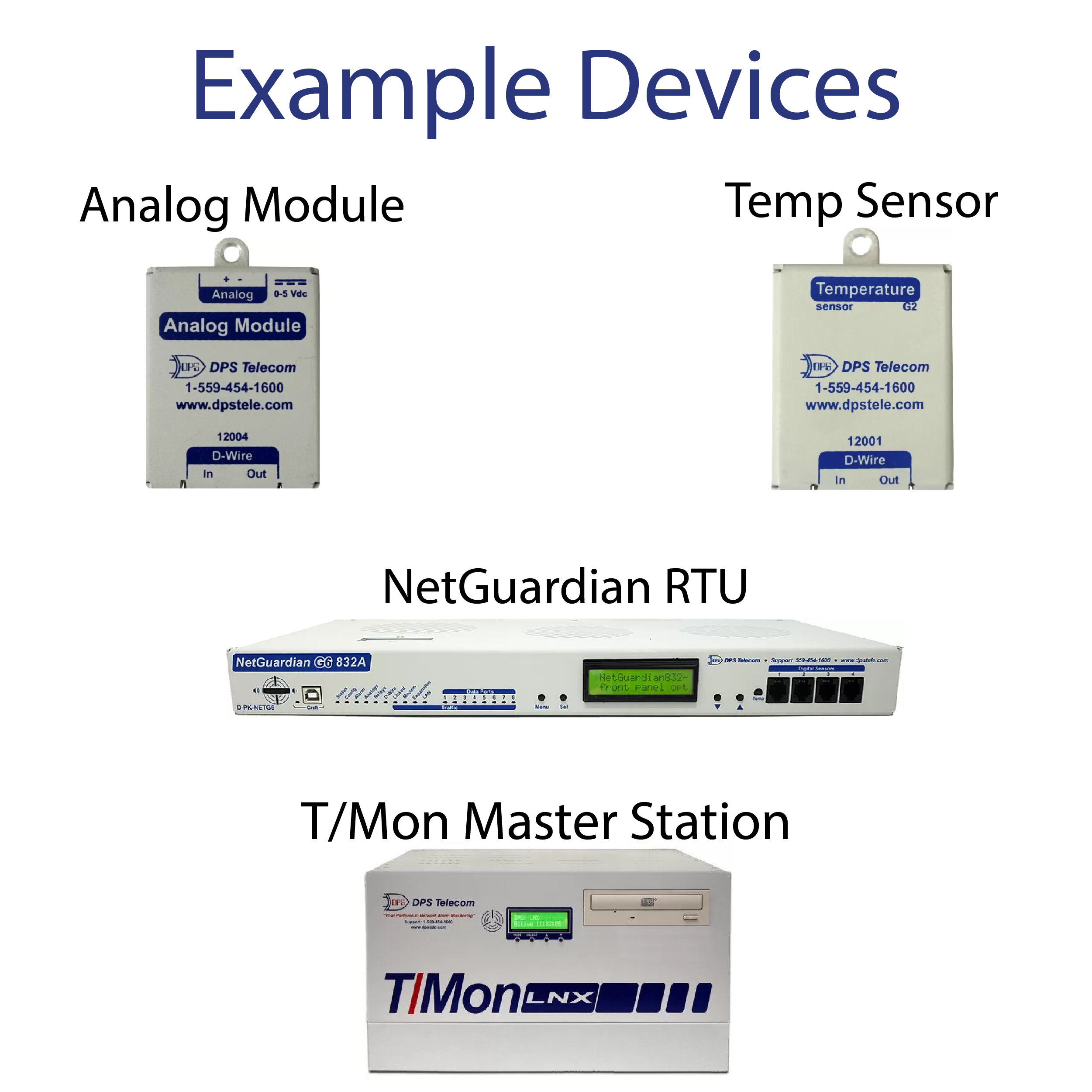

Using multiple kinds of sensors allow important data to be gathered, then forwarded to you by a remote telemetry unit (RTU). This creates an effective monitoring system that gets information about your equipment, transport gear, and environmental conditions.

Since manufacturing and providing monitoring solutions is what we've been doing for more than 30 years, we know that having the right sensors for your scenario is the first step for an efficient monitoring system. However, if you are new to the monitoring world in any way, you might not know yet all the things your monitoring system can do for you, therefore you might miss the chance to invest in a sensor you actually need.

To avoid lack of visibility over important aspects of your network, it's critical to know which sensors there are in the market today and which ones you need. So, let's take a look at the top 5 most important sensors for remote sites.

Before anything else, it's important to keep in mind that the best sensors for your network will ultimately depend on exactly what you want to do and monitor. However, there are some commonly used sensors that help monitor critical conditions to deliver a more reliable level of uptime. They are:

A temperature sensor is one of the most simple, yet valuable pieces of equipment available to monitor your server room, server closet, data center, or other telecom environments.

Server and other electronic equipment, by their very nature, generate large amounts of heat. If this heat is not monitored with temperature sensors, thermal shutdown are bound to happen. This can lead to network downtime and gear damage. It's possible that thermal shutdowns won't happen in time. That can cause equipment damage and data loss.

Temperature sensors are simple, compact, and cheap devices. They usually give you an analog temperature reading within one degree Fahrenheit of the actual temperature.

Temperature sensors come in two basic varieties.

Discrete alarm temperature sensors

This type of temperature sensor operates much like your home thermostat. Just like you do at home to stay comfortable, you would specify a lower bound and an upper bound of acceptable temperature in your server room, telecom site, etc. any temperature above or below this ideal range would trigger an alarm notice so that you could take corrective actions.

Analog alarm temperature sensors

An analog temperature sensor allows you to monitor the actual temperature at your site in near real-time. Instead of knowing that your temperature was just "too high" or "too low", you would know that the temperature was, for example, 90 degrees F.

You can use your analog values to send alarms based on user-configurable thresholds. You can have different thresholds for low critical, low, high, high critical temperature alarms. You would also be able to inspect the live temperature values in detail at the remote site.

Are you adequately protecting the physical security of your sites? Or do you leave your expensive and mission-critical equipment vulnerable to thieves, vandals, and other unwanted visitors?

The good news is protecting your equipment doesn't require a complicated solution. A well placed motion alert sensor could make all the difference.

Motion sensors provide you with the instant notification you need to react to intruders. Discrete motion sensors can even do things such as turn on a light or send an intrusion notification when movement is detected within its field of vision. Potential points of entry should be protected by motion sensors.

The primary damage caused by an outage is obvious: if commercial power fails and you don't have a backup power supply, the site is eventually going to go dark - which means you'll have downtime.

A power failure sensor will send alarms whenever power is disrupted for a specified amount of time.

If you rely on batteries anywhere in your network, then you probably want to know if they're outputting power. The last thing you want is for commercial power to fail then find out there's something wrong with your backup batteries.

You can avoid this entire issue by simply monitoring battery voltage or current. Specialized tools like the DPS Battery Voltage Monitor (BVM) are designed specifically for this, allowing you to track individual cell health rather than just the string total.

Remote sites usually run off commercial electricity, with some wind turbine and/or solar source to supplement. Some gear, however, requires liquid fuel that requires regular refueling for operation. But, how do you keep track of fuel levels for remote sites, especially at multiple locations?

When it comes to monitoring how much fuel is in your tanks, many options exist. Some are basic sight-only solutions. Either open the cap and look or maybe you get lucky and have a view port or a gauge to look at. This requires techs to be in the field constantly to track levels manually. Which not only increases costs through commuting and labor expense, but also has room for error. If a mistake results in a fuel delivery delay, you could have downtime at a site.

Some solutions may work well for DIY projects. However, when it comes to industrial applications, there are more efficient solutions. That's where fuel level sensors come in.

Using a variable resistance component and a float, fuel level sensors provide a signal that varies between two stop values. These sensors typically provide a 4-20mAmp or 0-6Vdc output. The signal can be monitored by an RTU using an analog input. This data can be processed locally against thresholds (ideally user-configured) for out-of-range conditions and local alert. The remote monitoring system can also forward this information to its Network Operations Center (NOC) for a higher level of monitoring and control.

Note that this information is analog, which means it provides basically a real-time indication of the liquid level. Alarm events are generated by the RTU after comparing the monitored level against one or more thresholds.

Apart from the previous five sensors, there are some other sensors that are usually deployed in many remote sites.

High humidity can lead to short-circuit expensive electronic components or at least create spurious unexpected connections. On the other hand, low humidity can dry-out seals and other protective elements. It can also increase the chances of static electricity discharge with possibly catastrophic effect on sensitive electronic circuits.

Weather fluctuations can make humidity levels highly unpredictable, so monitoring the humidity of your facilities with sensors is necessary for maintaining network stability and preventing failures.

A humidity sensor is a device used for providing ongoing measurements of the air's relative humidity. This works by running an electrical current between two nodes and then monitoring the amount of voltage created by the air's moisture.

In telecommunications, humidity sensors are important for remote monitoring and control for humidity levels and ensuring the safety of your electronic infrastructure.

Whether or not you've ever had to deal with theft or vandalism before, your unmanned sites conveniently located in the middle of nowhere are vulnerable.

Door sensors keep your important network equipment protected, as you receive notifications the instant someone tries to gain unauthorized access to one of your sites, or if someone enters when they're not supposed to.

Smoke sensors are critical safety devices used in every single home - your sites shouldn't be an exception.

There are a number of ways a fire could break out at a site: overheated equipment, electrical short, wildfire, etc. You can't really control when a fire could start, but you can take some extra steps to give yourself time to respond with a smoke detection sensor.

Monitoring your propane tanks can save you the hassle of running out of fuel. Depending on how much propane you use, you'll have multiple options for how thorough you need to monitor your propane levels. A floating sensor that gauges low levels may be all you need, or an advanced that reports live values may be more fitting - it all depends on what your specific scenario is.

Now that you know the most common sensors for monitoring systems, you might have an idea of what sensors you need to have at your remotes sites.

However, there are a huge variety of sensors from many different manufacturers, which makes it difficult to know which types and models are effective, and which should be avoided. It can also be confusing to incorporate new sensors into your existing monitoring system.

As an experienced network monitoring provider, we've helped many clients solve issues like those, and that's why we've prepared the SCADA Sensor Tutorial White Paper.

This white paper will teach you how to determine which sensors you need at your sites - and which core monitoring equipment you need for successful SCADA implementation. It will also will help you eliminate days of wasted time spent ordering, waiting for, and testing sensors.

Download your free PDF copy of the SCADA Sensor Tutorial and discover the tools you need that will slash your windshield time, improve your operations, and use sensors to squeeze more power from your monitoring system.

Morgana Siggins

Morgana Siggins is a marketing writer, content creator, and documentation specialist at DPS Telecom. She has created over 200 blog articles and videos sharing her years of experience in the remote monitoring industry.