Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayI just got back from an excellent trip to Dallas and the surrounding area. I spent 3 days manning the DPS trade show booth at Distributech/Powergen 2022, then visited two clients the following day.

Thank you very much to the 80+ of you who stopped by our booth to discuss remote monitoring projects, to our long-time clients who said "hi", and even you surly "booth bandits" who trick-or-treated some lovely DPS screwdrivers and USB drives. All are welcome at the DPS booth!

Staffing the show, and especially visiting our clients at their Texas offices, allowed me to see the DPS buying experience through new eyes. I rediscovered much of what's important to know about DPS before you buy.

Let me walk you through both of my client visits first, then I'll summarize the important things you need to know before choosing DPS for your remote monitoring system.

After the show ended, fellow DPS sales engineer JP and I drove about an hour to visit our first client of the day.

We met around a conference table with 3 employees of a major railroad. Two had been to visit our Fresno factory for our regularly scheduled free training classes a few years ago.

As such, they were already very familiar with the core DPS products (they have deployed several hundred) and philosophy. I did get to tell them about some new product developments they had not yet seen.

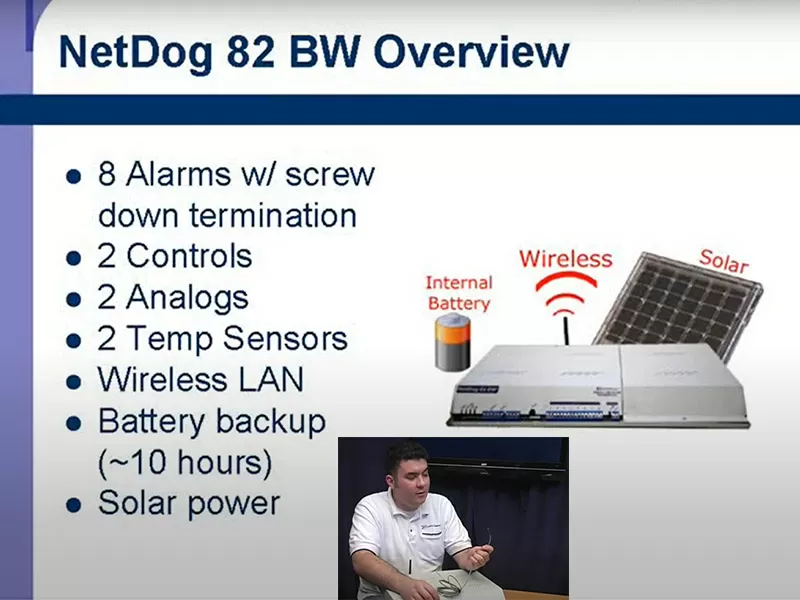

What was very interesting was telling their new manager about DPS. As I described the basics of NetGuardian RTUs and the T/Mon master station, and his employees added details from their internal perspectives, this manager asked a common question. He asked, "Do you guys ever end support for a generation of your gear?"

I pride myself in listening to all of my clients thoroughly, but I admit I nearly cut him off with an excited "No, we don't." Fortunately, I got the typical positive response to my answer:

"Wow. You guys are AWESOME."

In a world where obsolescence is commonly engineered into products to force upgrades, DPS is quite an outlier.

Since we had some time available, I also clicked through my YouTube DPS factory tour. When I present this in-person, I mute the on-screen Andrew and narrate over it live in the room.

It was fun to see the engineers who had visited DPS in California before recall the manufacturing and testing areas on the tour. They specifically recalled the EMI test chamber, so I jumped back a bit and showed that segment of the video.

Showing the DPS Metal Shop cutting aluminum from 8-foot sheets led to my second favorite client response of the afternoon. The manager said, "Wow... You guys really do it ALL, don't you?!"

I'm always thrilled when I have enough time during a client meeting to show snippets of my video tour. Because our in-house manufacturing philosophy is so unusual, it really changes your perspective when you see it for the first time. It tends to dissolve your (healthy) skepticism about whether I'm truthful when I say we can build you almost any device you need.

After finishing our rail meeting, JP and I packed back into our (very exciting...) Ford Fusion rental car to drive about two hours to our next client. Once we arrived, we gathered around another conference table with 4 engineers/technicians from the telephone co-op.

These guys found us on our website recently (just like you did today) with a web search for "PDU", "power controller", or something similar.

They have a straightforward project, but one that might require some customization. We're going to ensure that their microwave transmitters, plus some other gear, can stay online during lightning storms.

The idea is that, if one fuse blows, there must be some way to switch to a backup fuse remotely. Currently, it takes at least an hour to restore service when this happens. Rural Texas is a big place with long drive times between sites. That's an hour or more that customers might be cut off from being able to call 911, and it's always in poor weather that could endanger the safety of the company's responding staff.

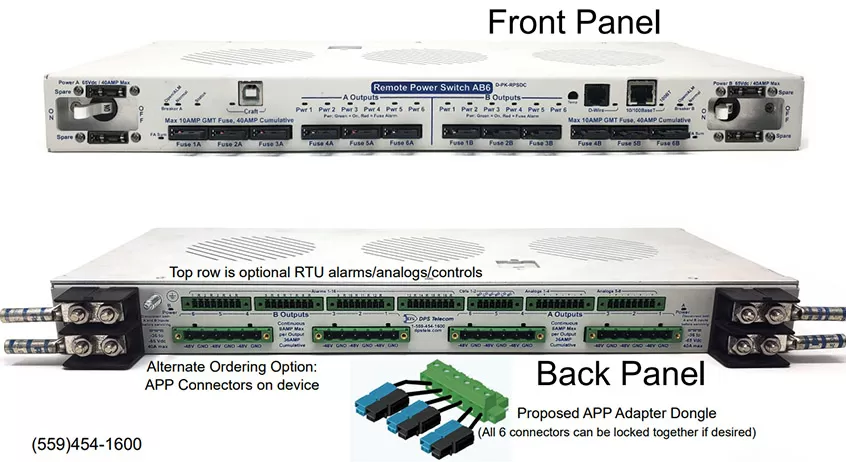

We had brought along our Remote Power Switch AB6 as an example of what we might do. Unfortunately, the conversation quickly got outside of my electrical expertise. I know quite a bit, but not everything.

Fortunately, I called Bennie, our hardware engineer who spent 14 years in the US Navy. He picked up, and we were able to have a good discussion with him on speakerphone.

JP had provisionally worked out a solution that would involve a simple new custom Y-dongle to provide redundant power (with redundant fuses) to the single power input of their microwave transmitters.

While a diode would prevent undesired electrical flow if there was voltage potential from one input to the other (and instant fail-over in the event of a power loss on one feed), it wouldn't likely do much in the event of a big lightning surge.

The group suggested that we instead focus on a manual changeover. Instead of having both inputs connected at all times through the Y-dongle, we'd instead have one of the inputs disconnected via relay. In the event of a lighting strike that blew the fuse on the first input, we could switch the relay to supply power from the other relay.

This could be done manually or, to protect against a likely communication loss due to microwave failure, via a Derived Control. On a similar DPS RTU, I demonstrated how an alarm on a NetGuardian can, with a customizable delay, trigger an automatic response via control relay. This would require a slight firmware modification, but all the building blocks were there.

Yes, this would take maybe a minute or two, but that compares very favorably to suffering through over an hour of service downtime, getting angry calls from customers, and perhaps creating liability in the event of a 911 call.

With this concept in mind, we suddenly had a good idea of the product we'd need.

I asked about capacity, and the general consensus was that 12 ports (supplied by 24 internal power feeds) would be the maximum amount needed. For some sites, even 1 or 2 ports would be useful.

As for site count, this is where I was really proud of what we'd achieved during the meeting. At the start, there was general agreement that perhaps 8-10 devices would be needed. This is right around our typical minimum order for free custom engineering.

After our meeting and the growing excitement around this new product, my clients thought that this new box might be useful at as many as 60 locations.

With all these notes, and clients who understand the DPS philosophy (I showed them the video factory tour), we now simply need to price out the new PDU (Power Distribution Unit) and send a PDF price quote. I tend to flex my Photoshop skills on projects like this, engineering the physical look of a box by moving ports around digitally.

DPS Engineering guides me to ensure the ports are pretty accurately located. Then, after we get the PO, Engineering has an excellent reference when creating the actual product design.

No matter what you buy from DPS, it will be reliable gear. When you call Sales, we'll help you to select an appropriate model from our sales catalog of off-the-shelf designs.

Still, what you don't know about DPS can actually hurt you. You might get good equipment, but you can also miss opportunities to really maximize efficiency and bring more gear under your monitoring umbrella.

To make sure that doesn't happen to you, let's review the 3 most important things you need to know about DPS before you make a purchase...

As you can see, I share my factory tour video at every reasonable opportunity.

Most clients seem fairly excited to have a look. If nothing else, it's a break from the usual workload.

Some clients aren't overly enthusiastic, but I press on anyway. In the majority of cases, my tour video ends up being an eye-opener that they did not expect.

(In short, you'd better put up a strong defense in a meeting with me if you don't want to see my factory tour.)

What is so important about the factory tour is that it's proof-positive that we really do make all of our gear in the USA at a Fresno, California corporate headquarters.

I think most people nowadays assume that "Made in America" is some kind of marketing gimmick. Maybe the major assembly is done overseas, and then a few screws are put in place once the nearly finished product arrives in a shipping container.

Seeing our factory in operation changes that perspective. You'll know without a doubt that DPS gear is made in America, with all the quality and purchasing flexibility (especially for government/security projects) that gives you.

Being an agile company, DPS can make adjustments to our designs. We have our own programmers, our own PCB factory, and even our own metal shop to quickly customize our metal enclosures.

As a result, we're willing and able to create entirely new custom designs for you. Maybe you need a new protocol. Maybe you need a few more ports. Maybe you need a very specific form factor.

Whatever unusual thing you need, DPS can do it for you. For most custom builds, all we ask for to lock in free development is a small minimum order, typically around Qty 11.

We'll always produce a single first article for you to test before building the rest, since everything remains subject to our 100% money-back guarantee. Because we'll change the design or tear up your PO if you're not happy, we don't want to build more than a single unit prior to the first field test.

Whenever possible, we'll also plan to visit you for the first field trial. There are always issues that crop up during a field trial, so it's best if someone like me and a DPS development engineer are on site when that happens.

I can recall a few DPS products from my early days at the company around 2008 that weren't exactly sales hits. In fact, we may not have sold any.

These are monitoring devices that seemed like they'd be a sure thing. The problem was, we didn't build them based on client input. Instead, we built what we thought was cool or important.

We do much better now, but my job at this point is to teach clients like you that we absolutely need your input to be at our best.

With an understanding of the two points above, you should now realize why sharing your thoughts with DPS is so important. Unlike anyone else on the planet, you (and your team) are uniquely qualified to provide design notes. Only you know the specific problems you face - and what gear might actually solve those problems.

This is a win-win scenario. You get a perfect-fit product to improve your network reliability. DPS gets a design that, by definition, network operators will want to use. You may not represent absolutely everyone doing similar work, but any device you help DPS design will likely find several other uses as part of our off-the-shelf catalog.

Now that you understand these 3 important facts about buying from DPS, what is it that you need us to make for you?

I'd love to come visit you in person during one of my upcoming field visits. Whether we meet face-to-face or not, the first step is always the same:

Give me a call at 559-454-1600 or email me at sales@dpstele.com and tell me what you're trying to accomplish.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...