Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayBridges are an important invention that has helped to transport goods and people across water or gaps in the land. It has helped us overcome obstacles (literally). However, bridges are subject to many situations such as traffic loads and environmentals.

As a result, monitoring bridges is an indispensable precaution. Monitoring your bridge will allow you to constantly maintain it and tend to issues before they turn into something bigger.

To monitor your bridge effectively, you will have sensors in place that are outlined later in this article. These sensors need to feed their information to a device called a Remote Telemetry Unit (RTU). RTUs can take discrete and analog inputs which most sensors use.

Here is a list of a key function in an RTU:

When shopping for an RTU, look for one that supports a 4-20 mA output range from your sensors. Most sensors in this field of monitoring output 0.1-5 mA. However, you want something that leaves room for unexpected events. Otherwise, you will not be getting accurate measurements or your RTU will be incompatible.

The first thing that you will need to monitor is the integrity of your bridge's structure. This can also be referred to as SHM (Structural Health Monitoring). This would involve using sensors to monitor different factors such as:

SHM will show you if your bridge has accumulated any damage. Over time, wear and tear can make your bridge a liability which contains multiple structural weak points. This could compromise your bridge and the lives of the people who cross it.

You can measure the outlined factors with different types of sensors such as:

Once these sensors are inputted into an RTU analog or discrete channel, it is then processed and transmitted using protocols such as Modbus and DNP3.

Environmentals such as wind and temperature affect your bridge. This is because of factors such as:

Your bridge will be prone to outside weather year-round. This means that environmental monitoring should be implemented no matter what type of bridge you are monitoring. Not only is it crucial for fixed bridges (bridges with no moving parts), but it is just as important with drawbridges.

Remote monitoring and control of your drawbridge is a requirement. A bridge has many moving parts in it. This is because there are more moving parts, and therefore, there is more of a chance for something to break such as:

If you are unable to monitor and communicate with your bridge, you will not have control over it. Finding a good SCADA system manufacturer will help you install the correct configuration to remotely monitor and control your drawbridge.

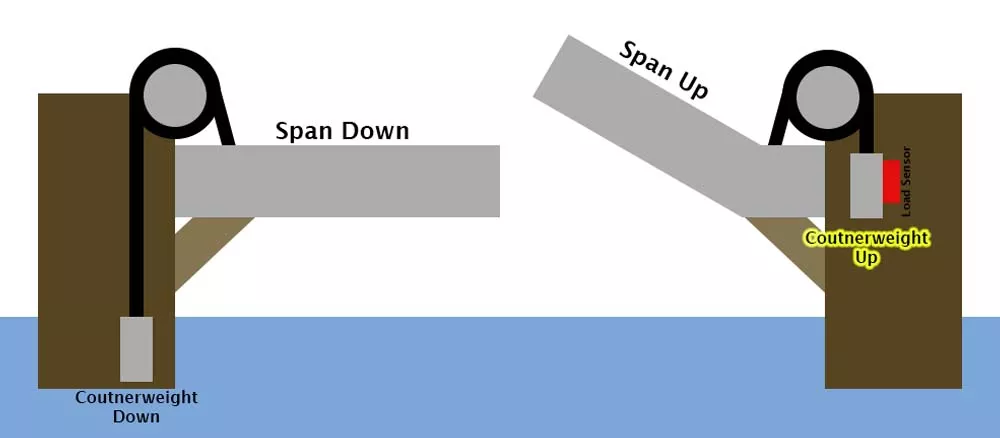

This can include position sensors to know whether a movable span is open or closed. This can be combined with load sensors for your counterweights and other pulling methods to monitor the load. Proximity sensors can also help you to know if a ship is approaching your bridge.

To reliably monitor your bridge, you would need a reliable SCADA manufacturer that can supply you with industry-tested equipment. To spot a good manufacturer, look for ones that provide:

Chances are, your bridge is either being monitored by a municipality or a military organization. This means that your scalability will help you future-proof your existing systems and tie them all together through Master Stations that allow you to have a centralized location to receive and annunciate all of the information you need.

DPS Telecom has been servicing major municipalities, transportation departments, and military bases since its inception. We offer you 40 years of expert technical support, as well as in-depth documentation and offered training.

We also pride ourselves on our ability to customize form factors to fit your specific needs. When a client does business with us, we want them to treat us like their own personal engineer.

If this sounds like something that you may be interested in further discussing, or if you perhaps have further questions that were not answered in this article, please feel free to reach out to me with any questions.

Even if we do not end up being the right fit for each other, I will still try my best to point you in the right direction.

Call today at 1-800-693-0351 or E-mail me at sales@dpstele.com

Ziad Alezabi

Ziad Alezabi is a Application Documentarian at DPS Telecom. He reviews successful DPS client projects and reports on the best practices that you can use to successfully reach your own project goals.