Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayYou may not worry about your monitoring equipment on a day-to-day basis - under normal circumstances, you expect it to work as it is intended to. But what about during a storm, or extreme temperatures? That's when you need your monitoring equipment the most. How confident are you in the durability of your monitoring equipment during unusual conditions?

Simply assuming your equipment will withstand an extremely hot Summer or a series of power outages will end up costing you a lot in the long run. Not only can extreme conditions force you to replace vital equipment, but they can also cost you windshield time. You need to be sure that your equipment will be ready for any condition. You can't afford to replace equipment every time your remote site encounters a bit of stress (temperature, EMI, etc.).

While many manufacturers test their monitoring equipment, the extent of the testing may be questionable. How do you really know that they test what they claim they test? Or, that the equipment you purchased actually passed the testing? Your monitoring equipment gives you visibility of your other vital equipment. You can't just blindly trust that the manufacturer has put in the testing necessary to keep your network online.

When purchasing monitoring equipment, be sure that you are getting the best. Only purchase equipment from a manufacturer that tests their product above and beyond what is necessary. It must not only function properly day-to-day, but also under the most extreme conditions. Look for a manufacturer that tests:

DPS Telecom knows how vital your monitoring equipment is to the well-being of your entire network. That's why they subject all of their equipment to rigorous testing. This ensures that your network is in the best hands possible. By testing all of the components in each unit under extreme conditions, DPS can be sure that their RTUs will stand up to even the most extreme conditions. DPS conducts several rigorous tests on every model manufactured as well as some on every single unit.

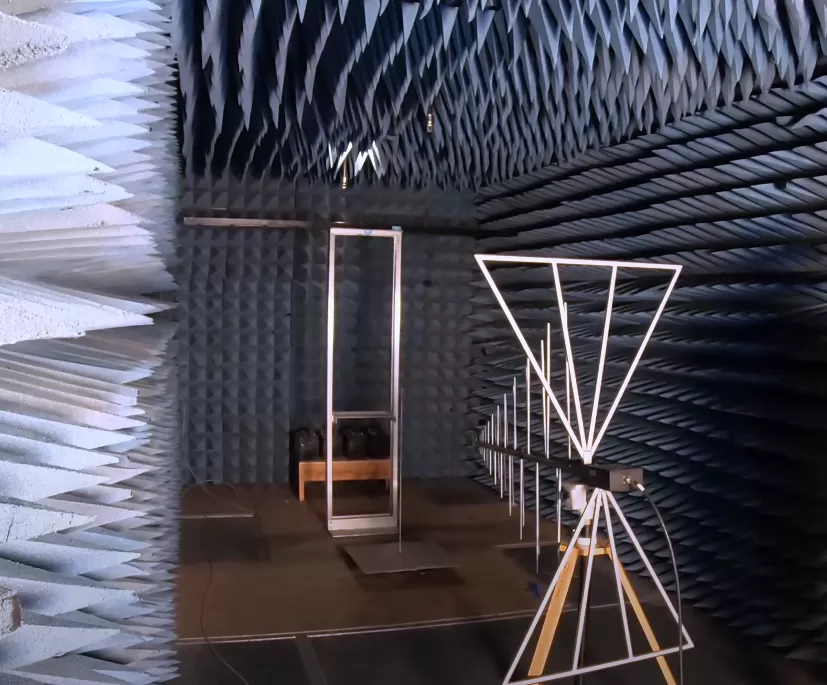

Currently, DPS conducts several product tests, including:

Tests are extremely good indicators of equipment quality, but they cannot 100% match the conditions and stress your equipment will face. Proven design is the ultimate test and the greatest proof of quality. While DPS Telecom offers custom units, the main components have been time-tested and proven to last. DPS Telecom equipment has been field tested and widely distributed. With DPS Telecom gear, you can be assured that your equipment is built with a proven design that will stand the test of time.

Your monitoring equipment is your window to your network. You can't afford to buy monitoring equipment that is untested and unreliable. Make sure that you have visibility of your system, even in the most extreme conditions.

To receive a price quote or ROI analysis, call 1-800-693-0351.