Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat Today

Here at DPS we believe that our products should provide solutions and not headaches. Through the years our products have been installed in locations too punishing for most equipment. From the frigid cold of Antarctica to the blistering heat of the Middle East, our products have been expected to perform in almost every extreme condition imaginable. To ensure this we put our products through a string of brutal torture tests to ensure that they'll continue to perform in even the most punishing conditions.

Using a Variable Power Supply we are able to control the voltage going to the units we are testing, which ensures that our products are able to work in extreme conditions.

One of our quality assurance tests we call the power voltage test. If all the sites our products have been installed at were running at a steady and consistent -42 to -56 volts we would be living in a perfect world. We're not! In the real world things like equipment failures, commercial power failures, overcharging and draining batteries can turn a stable -48 volt source into something you can't take for granted.

We recognized this and, because changes in voltage are often reasons alarms should be sent, we want to ensure that our RTUs continue to function as you would expect so you can get the critical alarms you need. The reason why we go to a lower voltage - typically below the point where other equipment shuts off - is to give you visibility of your sites until the last possible minute. We want your unit to be the last thing to fail. At only ___ mA, we don't tax your power system heavily.

Our products are subjected to a rigorous power voltage test lasting for several days. From below the minimum parameter voltage to above the maximum we make certain that our product boards can handle a diverse power range. Redundant power supplies and voltage override protection on the IO circuits provide multiple layers of protection keeping our units functioning when they're needed the most.

In addition to our power voltage test we put our products through a grueling power cycle test. In an ideal situation once the power at your site is on it stays on forever. We know this doesn't happen. When was the last time you had a commercial power failure? Have you ever had a site go dark? Often, when power is restored it can be intermittent. It may go on briefly and then, just as quickly, go off again. This may happen several times as power oscillates. These fluctuations often happen as your equipment is trying to reboot. You can't have gear that blows up if your power fails and then comes back. We power cycle uints hundreds of times to protect you from this especially frustrating kind of failure.

Here at DPS we test for these events. We do this through our power cycle test. Our power cycle test emulates these conditions in a controlled environment. From rapid power cycles to drawn out ones, we test our products under every combination of conditions we can envision. By going through multiple power cycles at different voltages we are able to design products that won't leave you in the dark.

Another test our products endure is our Temperature Chamber Test. Using our temperature control chamber we are able to test the boards at both extremes of the temperature spectrum. With the ability to control the temperature from -100 Celsius to 100 Celsius, we punish our boards to the point of failure. While the boards are in the chamber they are put through a wide range of programmed sequences and cycles. By stressing both environmental factors and load conditions we are able to fine-tune our products operating parameters. In doing this we are able to design products that work reliably and consistently in the most geo-diverse parts of the planet and in situations where your climate control fails or becomes impaired.

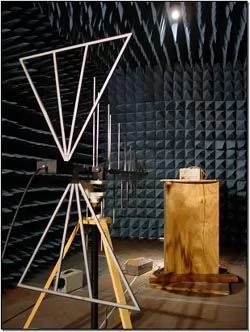

Electromagnetic Interference testing is one of the more advanced tests our product designs go through. We have invested over one million dollars to make sure our products go through the same EMI testing as it does during NEBS certification. Using our NEBS pre-compliance lab right on the premises, we are able to build NEBS compliance into the design of all of our new products. With a control room, anechoic chamber, and various antennas we are able to monitor the frequencies emitted by the various components on our products to make certain that they won't have a negative effect on other hardware. This enables us to build NEBS radiated emissions reliability into every product.

It's our commitment to quality that sets DPS apart from the rest.

From concept to hardware design to PCB layout to metal to firmware to software to the documentation to manufacturing to support - we do it all. This level of control allows us to ensure the highest standards of quality at every stage of production. Batch sample testing may work when you're producing a commodity but we produce custom-fit solutions and we treat them accordingly.

We guarantee that every unit that leaves our facility has been touched by at least two sets of hands. As only 100% testing of our products is acceptable we perform a burn-in test on every unit we produce. First, using built-in firmware diagnostics we are able to stress every component on the board independent of the final application. After this, we run the unit overnight and complete the diagnostic process again. This allows us to catch any product defect in the unit before it ships to our client.

DPS custom solutions are built on technology that has proved itself in thousands of successful deployments. We build custom products through modular hardware and software, structured development, and systematic testing, including NEBS compliance testing in our own pre-compliance lab. DPS serves a wide spectrum of industries from the major long-distance carriers, RBOCs, ILECs/CLECs, utilities, transportations companies, and Fortune 500 companies, all requiring dependable custom network reliability solutions. With the ability to provide custom-fit solutions for every monitoring need, clients are able to stay within their budgets without sacrificing the alarm monitoring functionality they require.

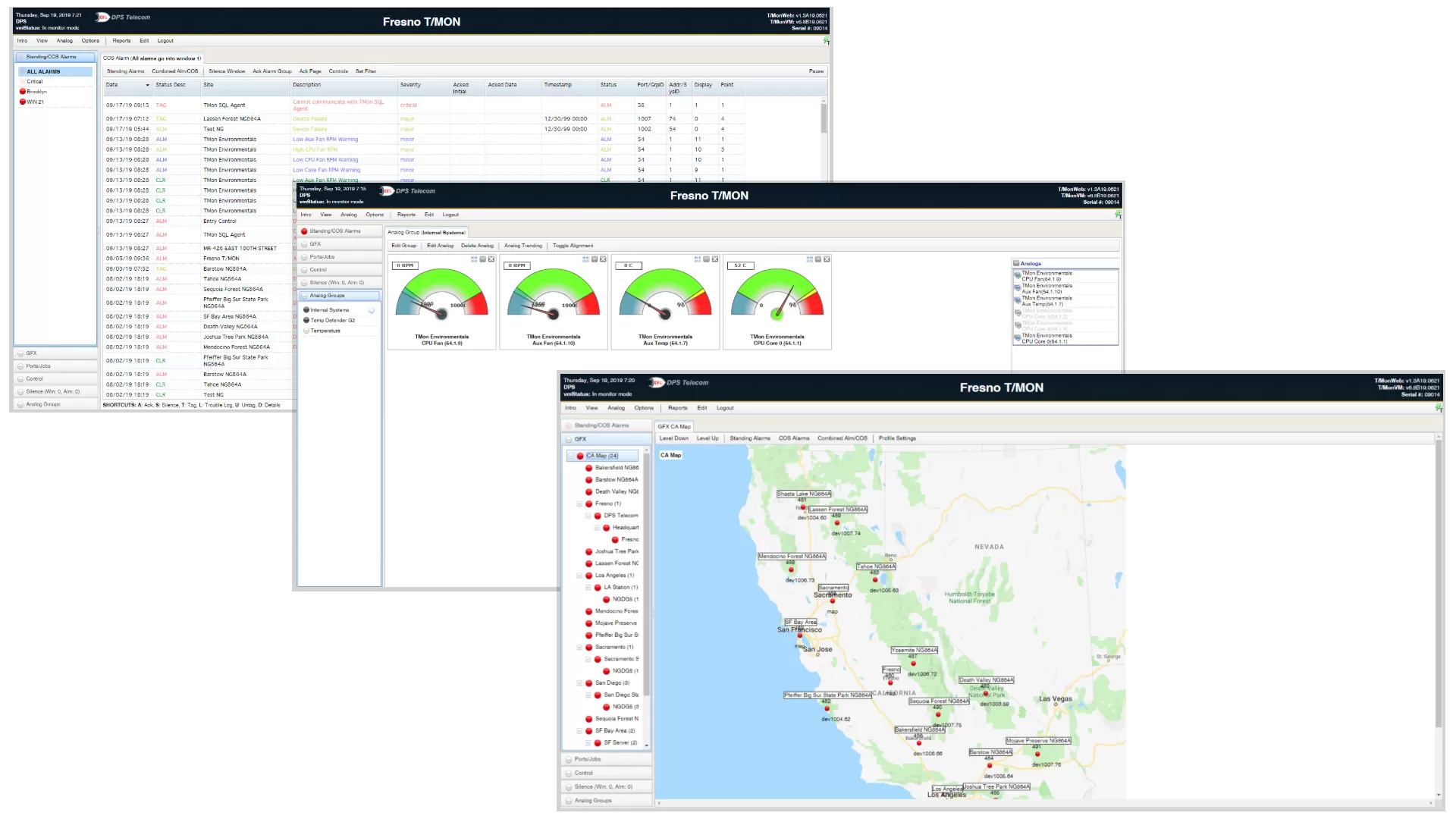

No matter what kind of equipment you need to monitor, DPS Telecom has a perfect fit solution for you. Whether you need small, versatile RTUs like the NetGuardian 216 or large, full-function RTUs like the NetGuardian 832A, or maybe the complete T/Mon LNX Remote Alarm Monitoring System master station, our solutions are 100% guaranteed to work for you - or your money back.