Download our free Monitoring Fundamentals Tutorial.

An introduction to Monitoring Fundamentals strictly from the perspective of telecom network alarm management.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayA temperature sensor device is one of the most simple - yet valuable - pieces of equipment available to monitor your server room, server closet, data center, or other telecom environments.

Frequently, devices that monitor temperature (and humidity), such as sensors, are ignored or overlooked by network operators. Unfortunately, it is incredibly important (and also quite inexpensive) to monitor the temperature range in telecom and IT environments.

Both extreme cold and high temperatures present a danger to your valuable telecom investment. It's important to have a remote monitoring system that allows you to keep an eye on both of these potential threats.

Servers and other electronic equipment, by their very nature, generate large amounts of heat. If this heat is not monitored with temperature sensors, thermal shutdowns are inevitable.

This can lead to service downtime and equipment damage. There's even a chance that thermal shutdowns won't happen in time. That can cause equipment damage and data loss.

Temperature sensors are not at all complex, quite compact, and relatively cheap. They typically give you an analog temperature reading within one degree Fahrenheit of the actual temperature.

Even those temperature sensors that operate like a thermostat have value. They alert you only when the site temperature is above or below the pre-determined threshold. While some monitoring is better than no monitoring, this method is limited and can have some major drawbacks.

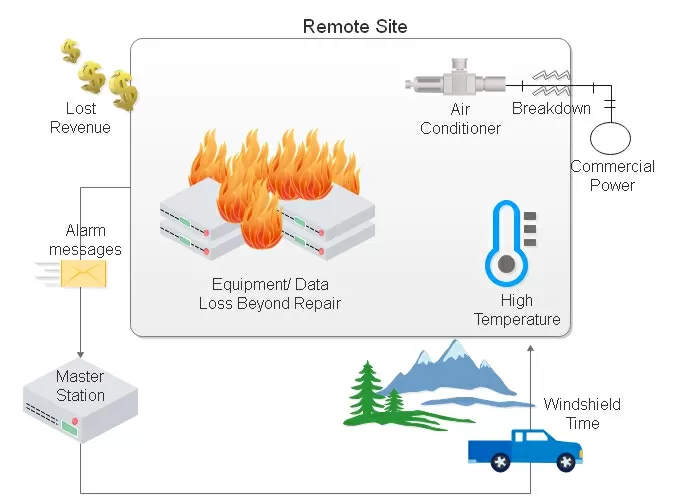

What if your HVAC system stopped functioning and you had no temperature sensors in place at your remote site? you would have no idea of the rising temperature until it was much too late. You'd have equipment damage or emergency shutdowns. That upsets both your customers and your bosses.

It's vitally important to monitor the temperature levels at your remote sites with temperature sensors. To get the most detailed visibility of site temperature, you need a remote that monitors four separate analog thresholds.

With four thresholds you can set separate major and minor alarms for both high and low temperatures. This gives you both an advanced warning if temperatures are starting to leave the optimum range (e.g., the air conditioner is not working right and the temperature has risen to 85 degrees F) and a final notification when temperatures have reached the danger point (e.g., the air conditioner is not working at all, and the temperature is 100 degrees F).

Temperature sensors come in two basic varieties. The simplest is a discrete threshold alarm. As I've explained, this type of temperature sensor operates much like your home thermostat. Just like you do at home to stay comfortable, you would specify a lower bound and an upper bound of acceptable temperature in your server room, telecom site, etc. any temperature above or below this ideal range would trigger an alarm notice so that you could take corrective action.

Unfortunately, the simplicity of this first type of temperature sensor can also cause trouble. If your alarm threshold was set to 85 degrees F, analog might indicate that the temperature was 86 degrees F or 186 degrees F.

You would have no idea of the intensity of the high temperature. Imagine that you have many sites with high temperatures during a power failure or heatwave. This level of detail would not allow you to prioritize your technician dispatches to the hottest sites first.

An analog temperature sensor allows you to monitor the actual temperature at your site in near real-time with readings every minute or less. Instead of knowing that your temperature was mere "too high" or "too low", you would know that the temperature was, for example, 96 degrees F.

You can use your analog values to send alarms based on user-configurable thresholds. You can have different thresholds for low critical, low, high, and high critical temperature alarms. You would also be able to inspect the live temperature values in detail at the remote site.

You may have access to very detailed temperature sensor data at any time. That doesn't necessarily mean that you can set automatic alerts when the temperature crosses a certain level.

Think about one more reason to select high-quality alarm remotes to deploy at your remote sites. You'll be able to specify several temperature thresholds that will trigger an alert message to you when they are crossed.

The best remotes will give you minor and major, over and under thresholds (4 total). In this way, and an intelligent alarm remote will provide dual functions. You'll get the continuous reporting of an analog temperature sensor. You'll also get the alert thresholds of a discrete temperature sensor.

Most analog temperature sensors need +12V power. In a telecom environment, equipment is typically powered with -48V. You could run your temperature sensor off of commercial power, but during power outages, you will lose your temperature sensor.

An industry best practice is to use an alarm remote ("RTU" or "Remote Terminal Unit") that will provide power to your temperature sensor from a -48V power source. There aren't many that do, but the NetGuardian 832A has a built-in +12V power supply option for powering your temperature sensors. This ensures your temperature monitoring is online when you need it.

Another advantage of analog value alarm monitoring is the ability to monitor the escalation rate of the analog values. This would provide you insight as to how fast the temperature is rising or dropping, allowing you to better dispatch personnel.

Monitoring several locations within your remote site for temperature is a good idea. It is recommended that you monitor the temperature around your critical equipment, as well as the outside temperature. Excessive heat cooks electronic equipment, even carrier-grade telecom gear.

It's best to constantly monitor temperature at your remote sites with four-threshold and live value analog alarms.

Heat also damages other equipment. High temperatures will dramatically shorten the useful life of your batteries. A lead-acid battery might last 10 years under ordinary conditions. That same battery will last only a year if it's consistently operated at temperatures over 122 degrees Fahrenheit.

In a recent telecom case study, a telecommunications company lost a remote site. Hundreds of thousands of dollars' worth of equipment were damaged due to the lack of temperature monitoring. With the added heat radiation of servers and equipment, the site quickly turned into an oven - cooking the equipment beyond repair.

It's important to monitor the HVAC systems that maintain your remote site environment. If you can catch an air conditioning failure early, you can intervene. You'll start repairs and fix the temperature problem before equipment goes into thermal shutdown. The site won't go dark and your customers will still be happy.

Don't forget to also provide a secondary power supply for HVAC systems. There is an often-overlooked aspect of power outages. Your telecom equipment will continue to run on backup power.

Air conditioning, connected only to commercial power, will still be offline. Imagine having the perfect array of temperature sensors in place. You're ready to go.

Then you can't respond quickly enough because you have no technicians near the failed-HVAC site. The equipment keeps running, the heat keeps rising, until the temperature forces a thermal shutdown.

If you do not deploy temperature sensors at your remote sites, you will, sooner or later, suffer equipment damage. One excellent example of the type of damage that can result comes from the world of UPS batteries.

Ambient temperature around your backup battery cells must remain near the ideal level of 77 degrees F. a higher temperature degrades the cells, and a lower temperature decreases the capacity of the overall battery string.

Server rooms and data centers also need temperature sensors. At DPS, we've spoken with several clients who have suffered multiple server shutdowns due to air-conditioning failures. We typically receive a phone call that describes an all-too-common situation. It is:

"I need information about a sensor to monitor the temperature in my server room. We have a dedicated server closet but we've been having issues with the air-conditioning. Sometimes the AC will stop working for no apparent reason.

It just happened again today, and I want some type of device that will monitor this in the future if the temperature starts to rise. I need to receive an e-mail that will alert me that the temperature is getting too hot."

In each of these cases, they successfully deployed small temperature sensors and a controlling RTU device. Both operate on the AC power typically available in IT environments. The sensors continuously monitor the server room temperature and send alerts as text messages or emails when there's an issue.

You can refer to this alarm features definitions page for definitions of unknown terms in this article.

Related Topics:

Related Products:

Vaisala - Temperature/Humidity Sensor

NetGuardian 832A (Large RTU to support multiple temperature sensors and other equipment alarms).

TempDefender IT. (Compact alarm remote designed for server rooms and data centers.)

All DPS Telecom products include comprehensive technical support. If you've purchased one of our products and are encountering any kind of issue, contact DPS Tech Support today at 559-454-1600.

At DPS Telecom, the representative who answers your call isn't an intern reading from a script. DPS Tech Support representatives are engineers who contribute to product development. And, if your problem requires additional expertise, the DPS Engineering Department that designed your product is right down the hall.

Help us connect you to the right engineer by filling out this quick questionnaire. Simply leave your contact information to get started, and we'll call you back. Most preliminary discussions are about 15 minutes, and afterward, we'll send you a custom application diagram of a recommended solution that'll make it easier to justify your project to management.