Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayHere at DPS, all of our operations - including sales, engineering, and production - take place at our single campus here in Fresno. This gives us an exceptionally high bandwidth of interdepartmental communication and allows for a rapid response to our clients' unique needs for custom solutions.

Whether creating a custom build for a client or developing the next generation of flagship products, this tight engineering-to-manufacturing pipeline gives our metal shop the ability to respond fast to our engineers' needs. As the metal shop manager, I've seen it dozens of times. We can reliably turn a new metal design specification into a fully assembled, finished chassis in less than two full business days.

We can do this because we have the right tools and the right manufacturing philosophy. These include extensive cross-training and internal promotion, ongoing improvement of processes and reduction of waste, and the continual development of a suite of online, and in-house tools.

Metal shop employees are expected to acquire all the skills necessary to turn an order into a finished product. Our employees all understand the fundamentals of water-jet and press-brake operation, powder-coat and silkscreen application, and hardware insertion. This gives our team a high level of redundancy and the ability to withstand any occasional staff absence.

In addition, we promote exclusively from within. Many of our top-tier employees got their start here in the Metal Shop or on the PCB Production floor. Their extensive knowledge of company operations makes them an important component of our lean business model.

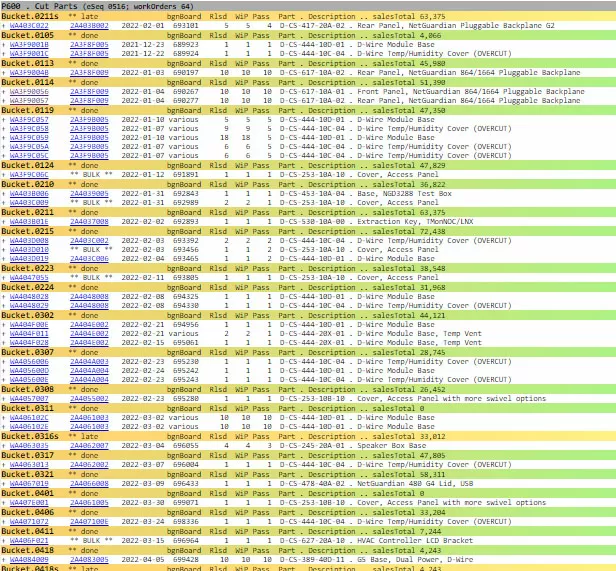

We use a massive suite of online tools, developed by our own software engineers, to help us keep track of all the processes and information we need to be an effective organization. Every sales order is electronically filed and broken down into unique parts. Each part receives its own identification number.

Using our online tools, we log every process performed on every part as it moves through the shop, from the water jet to the assembly table. In the case of process failure, the online event log gives us a place to capture information - which enhances our ability to identify errors and improve standard processes.

These standard processes are documented and hosted online, which gives us the ability to train new employees with exceptional speed. Clearly documented procedures help us avoid the kind of "tribal training" that makes an organization susceptible to the negative impact of changes in staff.

I've seen this firsthand a number of times. In the wake of an unexpected employee departure, DPS staff have the tools we need to hit the ground running with virtually zero down time. All of the knowledge required to maintain our process is available online at the click of a button.

Although large batch sizes are often thought to generate the best "bang for your buck", this approach actually causes a number of wasteful side effects. Overproduction creates a large and wasteful surplus of "just in case" inventory. This inventory accumulates dust, takes up space, and causes congestion on the shop floor.

Sometimes, this excess inventory becomes damaged while being transferred between storage spaces. Employees find themselves rummaging through piles of spare parts, often literally tripping over things they might need someday while on their way to find the things they do need today.

This overproduction introduces unnecessary bottlenecks by taking up time and resources that could be used more effectively elsewhere, substantially reducing the ROI on staffing and machine maintenance and causing missed shipping dates.

We have a much different manufacturing philosophy. Every part is made to order as our clients need them. Rather than taking shots in the dark, we take advantage of our tools to make informed decisions about what to make and when.

Our production teams use an online shipping schedule to stay in lock-step with each other. Here in the metal shop, we are very careful not to produce metal chassis unless their corresponding circuit boards are ready.

The online Shipping Schedule keeps our production team on the same page about expected shipping dates. We also keep batch sizes small. This gives us space to evaluate our process and calibrate our machines so that small errors are never allowed to cascade into big problems. Bottlenecks are avoided and rework is eliminated so that finished products move smoothly and quickly through stages of production on their way to you.

At DPS, we practice what we preach. Our campus is ground-zero for the development of better remote-monitoring solutions. We even use our own RTUs in the metal shop to monitor environmental data and a number of machine contact-closures. This helps us gather the data we need to identify unnecessary costs and improve our processes.

We embody the lean and responsive business model that we aim to help our clients achieve - that's why we're the best choice to help you achieve your goals for increased network visibility, cost reduction, and improved uptime.

Are you in need of a unique monitoring solution that we can help you with? We'd love to work with you. Give me a call at 559-454-1600.

Bob Berry II

Bob Berry manages the DPS Telecom Metal Shop. This facility, right across the street from DPS HQ, creates all of the aluminum chassis for NetGuardians & T/Mons.