Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayWhen a major utility contacted DPS, they were dealing with a costly problem: downtime during a storm caused by an empty generator fuel tank. They had no warning until the site went dark.

This particular project is an amalgam of similar generator and battery-monitoring crises I've helped solve over my 18 years at DPS. I'm sharing it here as an educational scenario to show you how we approach building (or selecting from our catalog) the right-fit RTU every time.

Here's how we worked together to solve this utility's fuel-tracking, battery, and site-security issues - without reinventing the wheel.

When Sarah, an engineer from the utility, reached out, the first thing she mentioned was the storm-related downtime:

"Our backup generator failed during a storm because the fuel tank was empty. We had no idea, and the site went down for hours."

Her top priority was generator monitoring. But as I've learned from similar projects, one problem often uncovers others.

That's why I asked a series of exploratory questions to understand the full scope of what they needed.

"Can you tell me more about the generator?" I asked. "Is it diesel or propane? And what kind of fuel tank are we dealing with - horizontal, vertical, or underground?"

"It's a diesel generator with a horizontal tank," Sarah explained.

"Does it have MODBUS output or just discrete contact closures?"

"It does have MODBUS, which should give us better data," she noted.

This was great news. MODBUS allows for detailed fuel-level tracking. That means the NetGuardian RTU can alert you before a tank ever gets dangerously low - and you don't have to install a third-party fuel sensor. You also get a bunch of other generator diagnostics.

Next, I asked about other problems. One issue rarely exists on its own:

"What about other systems at the site?" I asked. "Any batteries, HVAC units, or doors to monitor?"

"Batteries, definitely," Sarah said. "We've had surprise failures there. HVAC is less of a concern, but door security might be useful because we've had break-in attempts."

"Got it. For batteries, do you want to monitor each cell voltage or just the string voltage?"

"String voltage should be enough for now," she replied.

"And for door security, do you have door sensors or do you need them from us?"

"We'd need new door sensors," she confirmed.

We then covered the site environment to ensure the RTU could be powered and would fit in the available mounting location:

"What power is available to run the RTU? Is it -48V DC, +24V DC, or something else?"

"We've got -48V DC at all our sites," Sarah said.

"And what about connectivity - do you have LAN, or would we need cellular options?"

"We have LAN at every site," she replied.

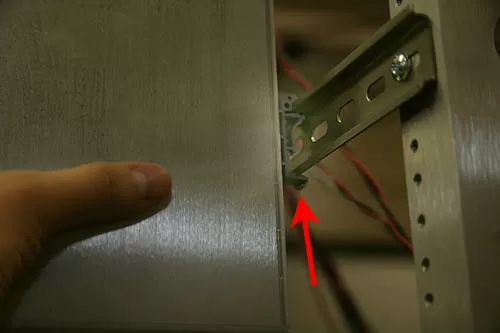

"Any mounting requirements? A 19-inch or 23-inch rack, DIN rail, or wall mount?"

"We prefer 19-inch," Sarah decided.

No monitoring system is worth anything unless it actually tells you there's a problem:

"How would you like to receive alerts - via email, SMS, or both? Do you have a central master station like T/Mon, or are you relying on standalone notifications?"

"We have an existing SNMP manager that should receive the alarm events," she said.

Finally, I focused on the big-picture outcome:

"Beyond solving the immediate generator crisis, what's your ultimate goal here? Reducing downtime, avoiding fines, streamlining maintenance?"

"All of the above," Sarah explained. "But downtime is definitely the biggest concern. That storm incident was incredibly expensive for us. We don't want that to happen again."

By this point, I knew that an off-the-shelf RTU from DPS would meet at least 80% - if not 100% - of their requirements. Rather than push a custom build when it really wasn't needed, I chose a proven design: the NetGuardian 832A G6. It offered all the functionality they needed right out of the box:

Off-the-shelf solutions like the NetGuardian 832A G6 are often the smart play when your site parameters (voltage, mounting, connectivity, etc.) match up well.

But remember that, at DPS, we keep a custom-engineering team in-house for the other 20% of projects that need special capacity, new form factors, or unique I/O signals.

If Sarah had asked for a more specialized form factor or a brand-new protocol, for example, we would have likely chosen to make a small run of custom units. This is also how the DPS product catalog continuously expands.

The lesson here is universal:

Whether you manage a power utility, telecom sites, or any other remote facilities, DPS has a monitoring solution that can meet your needs.

If you're facing generator run-outs, battery failures, or door-security breaches, let's find a monitoring system that fits your network perfectly.

Contact us today at 559-454-1600 or email sales@dpstele.com. We'll walk you through the same process that you saw here. We'll pinpoint your critical issues and select (or create!) the ideal RTU for your requirements.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...