Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayWhether you are running a public utility, emergency response department, telecom company, transportation business, or public service organization, the people on your network are depending on you in their time of crisis.

The number one thing you need to do to protect your critical equipment during any natural disaster is to monitor it with reliable, high quality equipment. There is no way to respond to potential damages in a timely manner if your team is unaware of conditions at your sites.

There are two major components to monitoring critical gear amid catastrophic weather events: detection and prevention. A high quality, reliable remote monitoring system will allow you to anticipate problems before they cause an outage. And when something does happen to your equipment, you will know exactly when and where the incident occurs, so that you can respond and restore your network immediately.

All sorts of extreme weather can cause a threat to the mission-critical gear at your remote locations. An effective remote site management system can help you proactively maintain your network infrastructure during events like hurricanes, lightning, flooding, wildfire, extreme temperatures, and other harsh conditions.

There are a few things you should do regardless of the nature (pun intended) of your weather challenges:

Make sure you have reliable telco-grade monitoring equipment for ALL of your vital gear. You need to be aware of how your equipment is running at all times, especially when expecting severe weather events.

Full visibility helps you to proactively care for your equipment, and promptly restore your network when something does happen. Everything you can do to prevent unnecessary downtime is an investment that will quickly pay for itself.

A power outage is likely to occur as a result of any natural disaster. Your network is only as reliable as its weakest link. When the power goes out, will your backup batteries, generator, or LPG tank prolong the operation of your gear until electricity is restored? You need to ensure that you have a backup power source that will reliably sustain your gear when you lose electricity from your main power source.

This will: 1) help you keep your network up and running when it's most needed, and 2) protect your critical gear from irreparable damage caused by an abrupt loss of power.

If you don't already have an uninterruptible power supply (UPS), you should implement one so that you don't lose power between a loss of commercial power and the time when your generator kicks on. You should test your UPS battery source on a regular basis - the more often, the better.

And in order to be sure your backup batteries and generator are constantly prepared to provide power when you need it, remote monitoring is necessary.

You can monitor your UPS batteries with a battery voltage monitor like the BVM G3 from DPS. The BVM G3 monitors the voltage, temperature, and internal resistance of up to 24 batteries.

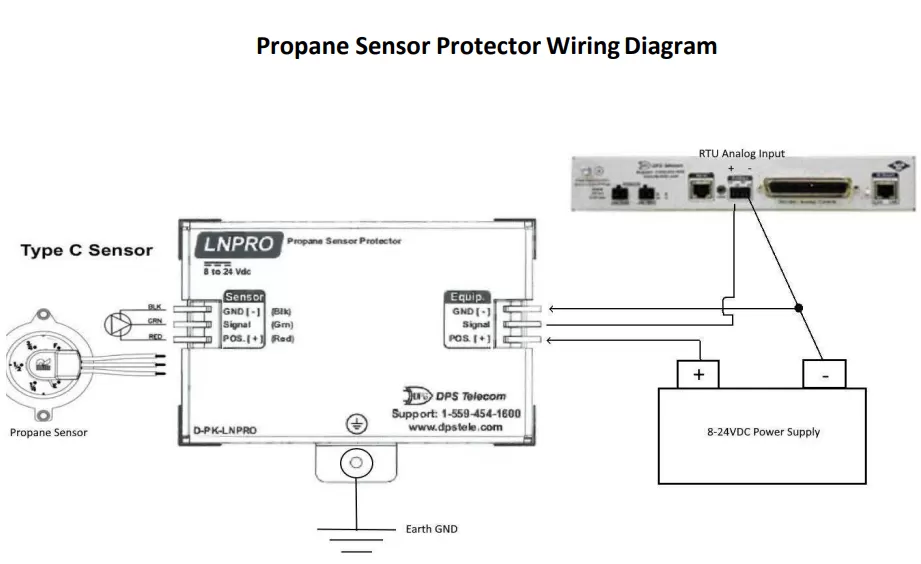

Monitoring the LPG tank that fuels your generator is as simple as switching out the gauge you already have with a potting cap sensor, which will relay the current fuel level to an RTU at your site. You can remotely monitor your fuel level in real time, and configure a threshold alarm to get notified when the propane gets below a certain level.

You can also monitor your generator with a simple sensor hooked up to an RTU so that you get a fail alarm if your generator fails a self-test.

Now that we've gone over what you should do to prepare for any weather event, let's get more specific. Preparation for hurricanes vs. wildfire will look a little different.

Depending on the hurricane and the location of your sites, you may or may not be able to completely avoid damage to your huts and equipment. But, with a combination of preventative measures and effective remote monitoring, you can minimize the impact of a hurricane on your network infrastructure.

Several DPS clients in tropical climates have monitored their infrastructure with DPS gear.

Cameron Communications, a telecom and entertainment provider in Louisiana and Southwest Texas, monitored their telecom sites with DPS equipment during Hurricane Rita in 2005. "We could see what happened through our entire network," added Keith. "It allowed us to make sure our Central Office generators were running," said Keith Liles, IP Data Supervisor.

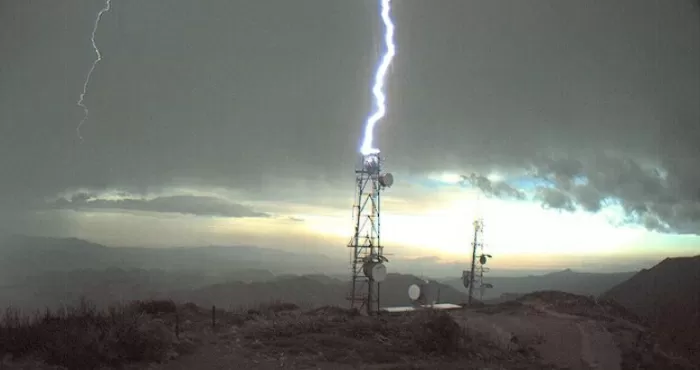

If you have equipment in locations where lightning is a concern, you should be attentive to how your equipment is wired and set up. If lightning hits your equipment or anything connected to it, you will likely lose much of your critical gear to a surge if you don't do anything to protect it.

There are a couple approaches to safeguarding your vital equipment from lightning.

You can use a lightning rod or other conductive material to create a path for electricity to get to ground. This will redirect the electricity so your equipment doesn't take the lightning strike directly.

A surge suppressor (such as the LNPRO from DPS) is designed to divert electricity through its grounding wire in the case that incoming voltage exceeds a safe level for your gear.

The other thing you can do to protect your equipment is to insulate it. Use non-conductive materials to insulate between vulnerable devices and any conductive materials (particularly anything made of metal.

Choose opto-isolated discrete inputs when you can. This means electricity is converted to light to protect your equipment from a surge. (DPS RTUs inputs are opto-isolated.)

One DPS client's homemade solution consisted of a two-millimeter-thick piece of plastic cut to the size and shape of a sensor and attached to it. This simple solution provided a buffer so the sensor didn't have direct contact with the wall.

In locations that get heavy snowfall, the snow can cause flooding when the weather starts to warm up again. If this is the case, or heavy rainfall or a nearby river is a concern, the first thing to consider is where your equipment is located. If possible, build your sites on high ground so that water doesn't pool near your vital equipment.

Your next line of defense is good monitoring. You can get environmental water sensors feeding into an RTU, which will set an alarm if water is detected on the floor or in any other location you may have a sensor. Another environmental sensor that can be helpful for detecting water at your site is an industrial temperature and humidity sensor. A robust monitoring system will also relay ping fail alarms, switch alarms, etc. so you will know right away if any of your equipment is not functioning or responding as expected.

If you know that moisture may be a concern at any of your remote locations, keep that in mind when investing in the equipment at your sites; that includes mission-critical gear AND monitoring products. If you don't have high quality, reliable equipment monitoring your vital gear, you might as well not monitor at all. You need to be able to rely on your monitoring system so that you can protect your equipment and maintain your network.

For smaller sites where you have cabinets in place, make sure you have high quality enclosures that keep moisture out. DPS sealed cabinets, for example, are tightly sealed with a rubber gasket to keep water from entering and causing damage to your vital gear.

One DPS product specially designed at the request of a client, the NetGuardian G5 RTU, has a conformal coating - this coating makes the unit resistant to humidity.

Predictive sensors such as smoke detectors and temperature sensors will provide data to let you know if a fire may cause imminent damage at your site. Even if it's not possible to go to the location due to the fire, you should, at least, have time to safely power down your gear (with a Remote Power Switch) and avoid an abrupt power outage.

If you have sites with propane tanks, a necessary preventative measure is to keep the area (at least ten feet) surrounding the tank clear of any debris or vegetation that could act as fuel for fire. The goal is to keep the LPG tank free of contact with flames.

Siskiyou Telephone, a DPS client providing telephone and internet service in Northern California, used T/Mon Alarm Master to monitor their network during the McKinney wildfire in 2021. They lost some of their fiber runs and had to lay temporary ground cables to restore their network. But thanks to their DPS monitoring equipment, they were instantaneously notified of a loss and its source, allowing them to recover as quickly as possible.

It was even more critical for them to have reliable monitoring with active fires burning and vulnerable temporary cables on the ground. The T/Mon lets them know when a certain site goes down. They get C15 switch alarms, low battery alarms, ping fail alarms, and more. The T/Mon has allowed Siskiyou Telephone to maintain reliable monitoring of their whole network during wildfire season.

In order to protect your mission-critical equipment from extreme heat or cold, you will need a remotely managed HVAC system and reliable monitoring equipment. In order for your vital gear to withstand harsh temperatures, you need to have remotely monitored and controlled heating or cooling.

Remotely controlling the ambient temperature in your telecom shelters is absolutely essential if your remote locations are exposed to extreme low or high temperatures.

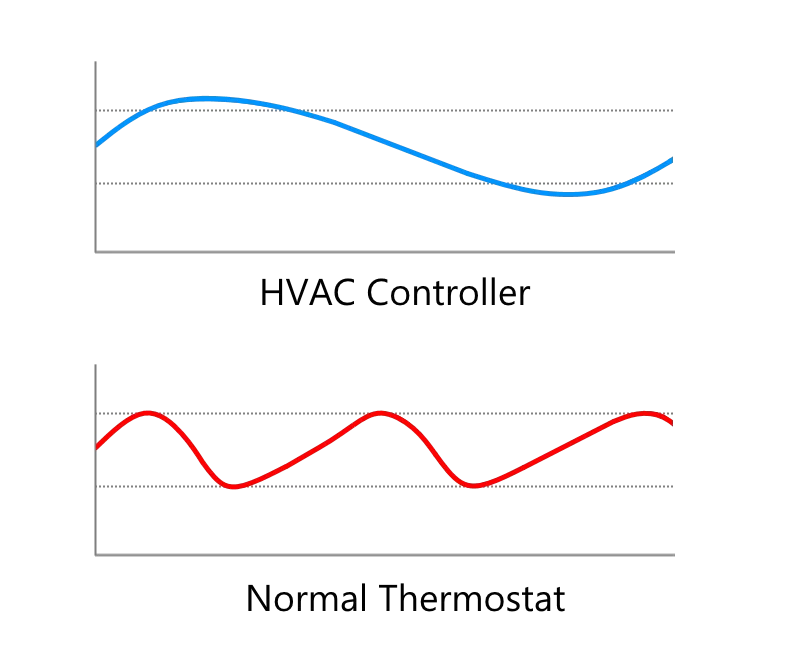

The most obvious way to manage extreme temperatures at your remote site is with an HVAC Controller. With a remotely managed HVAC controller, you can control the ambient temperature in your telecom huts from the Central Office or even a mobile phone.

The HVAC G6 from DPS is a lead-lag HVAC Controller. In extreme temperatures, your HVAC unit can get overwhelmed, which is why having a lead-lag HVAC system is a good idea. The HVAC G6 allows your HVAC units to be remotely programmed and controlled to switch periodically. This both extends the lifespan of your HVAC units, and helps prevent your units from overheating and shutting down.

Choose devices with industrial-rated operating temperatures. This means they were made to keep functioning properly, even at very high and low temperatures (-30C - 70C). Consumer-grade monitoring equipment is probably not going to withstand hot desert summers or Alaska winters. You can't afford to lose visibility of your remote sites at the times when your infrastructure is most at risk.

A Temp/Air Flow sensor mounted in front of a vent will let you know at what capacity your HVAC system is functioning. It will measure the rate and temperature of the air flow, so you don't have to waste windshield time heading out to a site to stick your hand in front of the vent and feel for yourself how well it is working.

In addition, something as simple as a door sensor can also help you to avoid a careless error like leaving a door propped open and allowing the outside air to enter the hut.

Your infrastructure stands the best chance against natural disasters and severe weather when you have a durable and reliable telco-grade monitoring system in place.

With over 37 years in the remote monitoring industry, DPS's products are tried-and-tested. Our team is knowledgeable and creative in helping you create a custom remote monitoring solution for your network infrastructure. If you can't find an ideal monitoring solution to prepare your remote sites for natural disasters and extreme weather, schedule a free-of-cost consultation and we will work with you to ensure you have excellent network reliability.

Get in contact with DPS to get your mission-critical equipment prepared for anything Mother Nature sends its way.

Haley Zeigler

Haley is a Technical Marketing Writer at DPS Telecom. She works closely alongside the Sales and Marketing teams, as well as DPS engineers, resulting in a broad understanding of DPS products, clients, and the network monitoring industry.