Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayDPS is a remote monitoring manufacturer, so we deal with the remote monitoring issues on a daily basis. I'm going to give you insights from the different industries that we serve. I've even included actual quotations from real DPS clients.

This information comes from a lot of different sources, and it doesn't really matter what industry you're in. If you're reading this, you're probably in the business of managing a telecom network in some capacity.

You might work for a telco (phone, wireless, TV, and/or ISP), a power utility (electricity, oil, gas), a railroad (national, regional, or subway/municipal), or a police/fire/911 agency. You could be employed by a state or federal government agency. We also get a fair amount of business from agriculture and hospitals.

Even if I didn't mention your industry, all of the remote monitoring information I'll be sharing with you here is pretty universal. All of the concepts here revolve around a common goal: 100% uptime in your network.

Let's get started!

As you read this, preventable waste is silently (and sometimes loudly) devouring your profits, increasing your budget consumption, or even putting lives at risk.

You may have the smartest, most well-intentioned team on the planet, but they can't effectively manage your large service territory if you don't give them the right tools.

Poor situational awareness happens when your remote monitoring system isn't correctly designed, installed, and provisioned. Your people don't receive clear, up-to-the-minute intelligence about every remote site, so they're stuck trying their best to "do a good job".

They drive out to sites for routine maintenance on a fixed schedule, not knowing if it's too soon or too late. They're woken from their beds by sudden network emergencies and even service-affecting outages - incidents that could have been anticipated and prevented as part of routine operations.

Think of the wasted budget dollars. You pay people overtime for work that could have been done during normal hours. You put unnecessary wear and tear on your fleet of trucks, burning money on fuel the whole way.

Equipment is damaged by overheating, under-voltage conditions, over-voltage conditions, and other detectable problems. The stress of feeling out of control shreds your employee morale, and that accelerates expensive turnover.

But all this spending is only half of your profit equation. You're also putting your revenue in jeopardy (whether you measure it in dollars earned or lives saved). In competitive industries, your customers can leave you for a competitor. If you're a natural monopoly like a power utility, poor service can mean big fines from regulators.

If you work in public safety, people in life-and-death situations need your radio systems and 911 dispatch to work every minute of every day.

When you don't have a good remote monitoring and control system for your network - no matter your industry - you're leaving money on the table. You're not doing your job.

I'm always amazed when I watch executives spend $100,000, $200,000, or more on infrastructure equipment - and then bristle at spending even $800 on protecting that valuable gear.

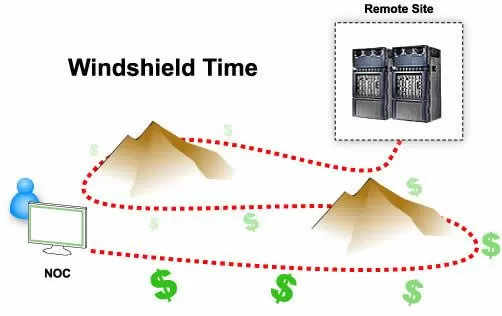

It's not just possible for a remote monitoring device to pay for itself after a prevented incident. It's common! This is perhaps most obvious on mountaintop sites that require a helicopter trip. When helicopters are involved, that $800 device will pay for itself at least 3 times over after eliminating a single site visit.

And that ROI math only counts the occasional, expensive problems. You also save a little bit each day by eliminating unnecessary truck rolls, reducing staffing and training requirements, and minimizing confusion.

This all makes remote monitoring some of the best and cheapest "insurance" you can buy, but it still goes chronically underfunded.

Among our clients who've learned the true value of remote monitoring, we hear phrases like "rounding error" and "spit in the ocean" to describe the cost of our equipment during a network expansion.

Your network, by design, covers a large geographic area. Your sites are unmanned. Some must survive for months without a visit.

Your resources will always be limited. No organization on the planet could justify 7x24 staffing of every building, hut, and cabinet. You need force multipliers to manage your widespread infrastructure with the staff you do have.

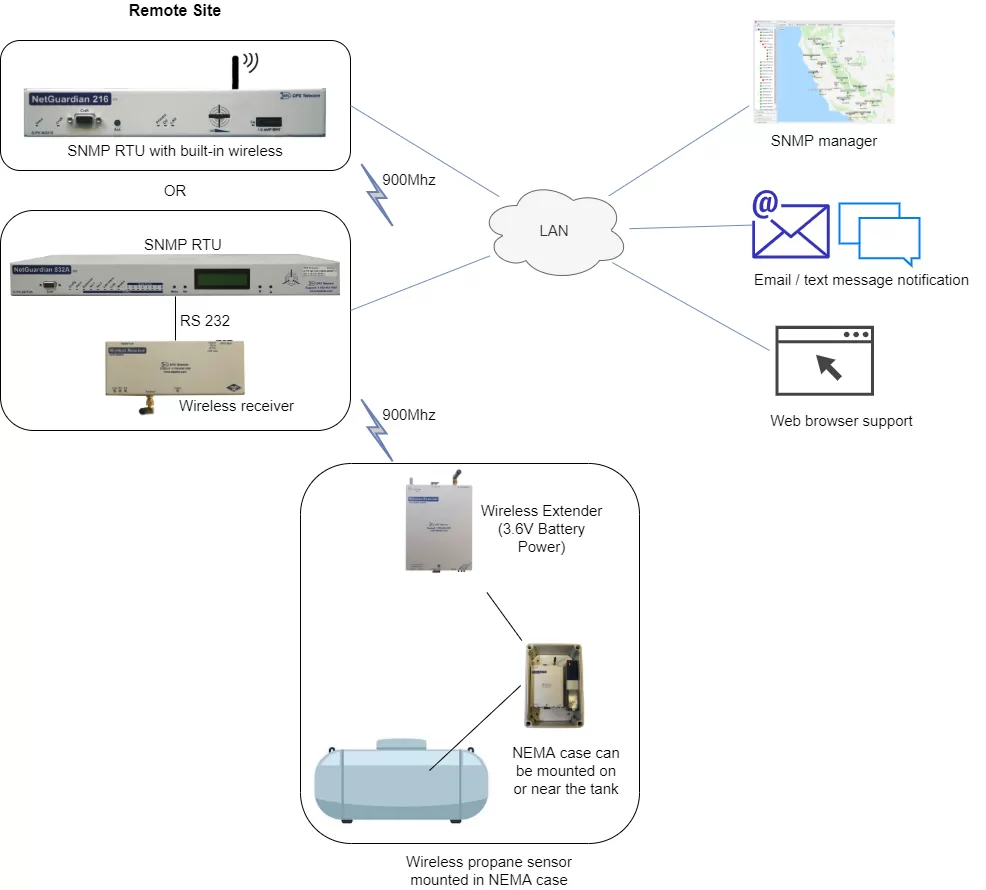

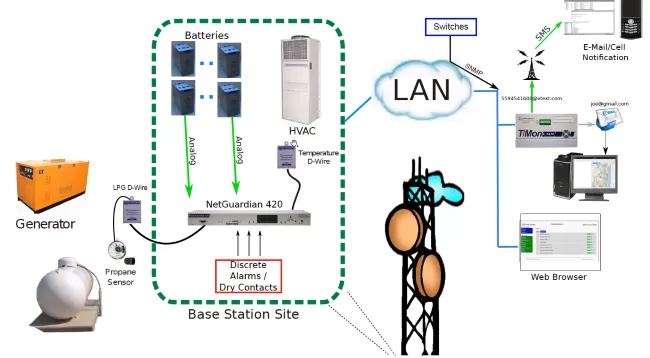

A good remote monitoring system will collect data from all of your remote locations, process it, and alert your staff in the correct way. Serious alarms will be clear and obvious. Unimportant "nuisance alarms" will be suppressed to reduce distractions. Alerts will appear on a console screen, as an email, or as an SMS text message.

If you do this right, your monitoring system will do what any good technology does: fade into the background. When the system is intuitive, your team won't waste time worrying about it. They'll get a clear mental picture of your network status and be able to respond appropriately.

"Do a good job" won't be your hopeful prayer anymore. You'll have equipped your team with the tools to reliably succeed.

"If people in the office don't acknowledge an alarm within a certain length of time, it will notify everybody out in the field - management, supervisors, technicians - to know what's happening in their areas."

-Tom Cantwell, NJ Transit

"We are looking to take the alarm master's email functionality and tie it into the company's email system. This would provide notification to all our techs as needed."

"We have a lot of unmanned locations. We need to have visibility of all our field equipment."

-Tom Cantwell, NJ Transit

"It takes 3 or 4 hours to get there, and it gets snowed in sometimes."

-Kurt Klein, U.S. Cellular

Your remote facilities are unmanned. You don't have somebody out there the vast majority of the time, so you need to have some electronic "eyes and ears".

In some service territories, it might take 4 hours to get to a site. In the winter (especially on mountaintops), sites can get snowed in. It might take using a snowcat or helicopter to get up there.

Helicopters in particular get very expensive very quickly (generally $2000-$8000 per trip), so having remote monitoring and control capability becomes even more important in those cases.

These are scenarios that demand proactive thinking. To do otherwise will harm your reliability and your profits. It can even risk lives.

If you're simply reacting to problems in your network as they occur, you're doing it wrong.

Ask yourself, do you get phone calls from people complaining that your service is offline? That should be your worst nightmare.

Your clients - whether they're coworkers or your actual customers - must be able to count on your service availability. You want to know about any problems immediately and be able to turn things around before anyone else ever knows.

Maybe you have a monitoring system right now, but it's just not very elegant. That's better than nothing, but you need to recognize the ROI you can achieve when you install remote monitoring that actually works.

When you can't tell the difference between a routine issue and a major threat to your uptime, you're forced to respond to the worst-case scenario. You rush out to the site because you don't know what's going on.

It might not be a big deal. Maybe it could wait until morning or the next maintenance visit. When you don't know because you're not collecting good remote intelligence, you have to race around and hope. That's just not a very good way to be.

Everyone knows the helpless feeling you get when you learn about something too late. "If only I knew, I could have easily done something," you tell yourself.

Slow, invisible failures in your network trigger that same feeling of dread. Here's one example I heard from a public-safety-radio client at a trade show:

Sadly, even this wasn't the end of the story. Even though they had the momentary inspiration to get some quotes and deploy a solution, they got busy with other work and soon forgot about the problem.

Eventually, it happened again in the same way. As this client learned, you don't get different results unless you actually fix the root of the problem...

Most workers with some amount of autonomy find themselves "firefighting" whatever new problem has cropped up today. That's a good thing to do, but your organization - at some level - has to also have a process to eliminate the root causes you've discovered.

If you don't focus on long-term improvements, you'll quickly get distracted by the next fire that breaks out. When that happens, all the learning you just gained will evaporate. You'll reset the ticking time bomb, just waiting for history to repeat itself. It always does.

Oddly enough, that's a frequent source of inbound calls to my office. When something bites you a second time, you won't remember specifics about the first incident, but you will remember that you've been here before. That creates a surge of "let's get this done" rage, especially if the boss assumed you already did.

A healthy chunk of my inbound quote requests are from companies like you who were burned by "the second incident" and forced into action.

It's one thing to experience something once before rolling out a solution (fool me once...).

Of course, I'd love for you to use the best practices I've collected for you here and be totally proactive. You'd set up a remote monitoring system and protect yourself from the beginning.

Still, I know this isn't always possible. There's a big jump between reading about profit-sucking waste and experiencing it firsthand.

Even if you don't stop your first incident, please don't wait around for your second helping of frustration. Make some calls, assess your options, and get something deployed before you get burned again.

This is especially true considering the number of different incidents that solid remote monitoring can prevent. You might be diffusing a dozen "ticking time bombs" with a single project. Once you have the right tools in place, you'll know exactly what's going on at all of your sites, all of the time.

When you're reacting to problems that you didn't see coming, think of all the effort you're wasting. You're running around trying to fix things that have already broken down.

When you make an investment in better situational awareness, you perform maintenance at just the right minute. You travel just when you need to - and no sooner. You take care of multiple things in one visit.

This all comes from the complete intelligence you gain with a modern remote monitoring system. You'll know when equipment is failing. You'll know what your temperatures and humidities are doing. You'll know your security status.

When you know all these things at all of your sites, there's very little left a chance. You'll have taken total control of your network.

As you can see, there's a lot to consider as you plan improvements to your remote monitoring and control systems. I can help you sort through it.

Just tell me what you're trying to accomplish. We'll create goals together and write up a plan to make them happen.

Give me a call at 559-454-1600 or email me at sales@dpstele.com

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...