Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayPolice radio sites around the country use underground propane tanks to power their emergency backup generators. When these tanks run low, it can take days or even weeks to get them refilled, leaving the site vulnerable in the event of a power outage.

The information is then transmitted to a central location, where it can be monitored in real-time. This will allow police radio site operators to know when their propane levels are running low and take steps to ensure that the tanks are refilled before they run out of fuel.

To help ensure that police radio sites have the resources they need to stay operational during an emergency, the Department of Homeland Security's Science and Technology Directorate (DHS S&T) is developing a new tool to monitor the levels in underground propane tanks. The system uses sensors to measure the pressure in the tank and identify when the level is low.

DHS S&T is currently working with law enforcement partners around the country to test and evaluate the new system. The goal is to have the system operational at police radio sites nationwide within the next few years.

Because so many of our remote site monitoring projects including propane tank monitoring, I'm very familiar with it. To help others doing research, I write articles and post videos about the technology fundamentals.

After performing a web search and skipping past consumer-grade options that are incorrect for government agencies, one telecom engineer found my article on propane tank monitoring and gave me a call.

That led to a site visit within a few weeks. I don't charge for most initial visits like this. That's feasible for DPS because I also visited the local power utility while I was in town to help defray costs. There is definitely an advantage to the very large install base we've developed since 1986.

There are a variety of problems that my client is aiming to solve with this project.

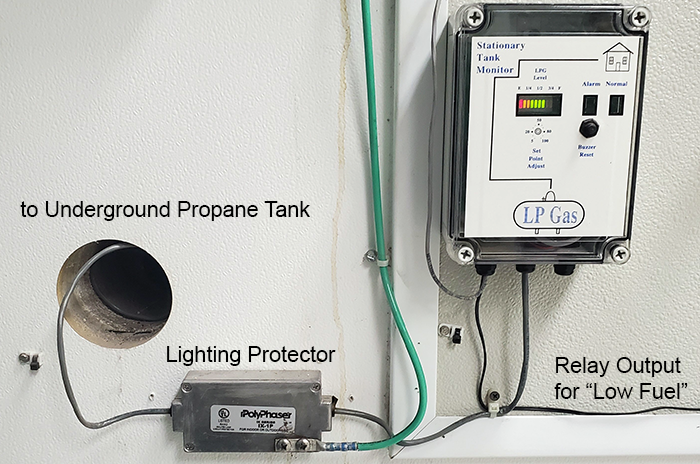

Although I didn't yet research its availability myself since my visit, my client reported that the Stationary Tank Monitor device model that he's currently using is discontinued.

He also noted that it reads the 0-5V analog from the LP sensor, but only renders a northbound contact closure. As a result, he can't know if a "Low Fuel" alert means 1% lower than the warning threshold or a totally empty tank.

As my client reported during my visit, "The LP sensor is very sensitive to lightning striking in the summer. That led to the installation of the PolyPhaser devices."

Unfortunately, those lightning protection devices weren't chosen to match the 0-5 VDC range of the propane sensors. "But they're 50-volt max instead of 5-volt, and tend to still allow the surge to reach beyond the PolyPhaser." That's not the fault of this particular PolyPhaser model or its engineering. It's just a functional tool that was not properly matched to the problem at hand.

It's also true that, regardless of PolyPhaser or any other protection device, LP sensors will still end up fried by lightning because they're on the "outside" of the protected circuit.

For my client here, this lightning damage is especially frustrating because their grounding practices at the sites are really good.

The problem goes beyond having to pay for new sensors, as even sourcing replacement LPG Hall Effect sensors has become difficult recently. I mentioned that DPS has stumbled into being a Rochester "distributor" of sorts, as many calls come in seeking the sensors we keep in stock.

My client also asked about our wireless propane option and wondered about viability with underground tanks. I'll be reviewing that with DPS Engineering back at our headquarters.

Due to chronic failures of sensors due to lightning, and the discrete-only output of the Stationary Tank Monitor collector device, my client and his team of technicians largely just end up driving to sites and reading the tank levels manually.

These truck rolls get an additional complication from about October each year until the spring thaw. In those months, there is no fuel truck access at many sites due to snow.

It is important to top-up the propane prior to the first big snow so there is a high chance of lasting through the winter.

Remote monitoring will also be helpful during those harsh winters, as propane levels can at least be monitored without the impossibility of sending a technician in a truck.

The site I visited (and most others at this police agency) has two underground tanks in parallel. Because of this, they only have one machine-readable gauge that summarizes the percent remaining in the pair of tanks.

The telecom engineer I worked with is very interested in being able to proactively view analog levels. T/Mon Analog Groups will likely play an important role here.

In this law enforcement radio network, there are over 100 total sites, with several more on the way. Each technician is responsible for about 16 sites within a region (7 regions total). The sites are all powered by -48 VDC.

Some sites do not have radio equipment. They're just microwave hops. There are a handful of sites with diesel generators instead of propane. I explained that the specific sensor is a different model, but it's the same electrically when it hits our NetGuardian RTU.

The Motorola head-end and 48-point MOSCAD RTUs already installed are fairly new, so it makes sense that this agency wants to continue using them. As they described, if they run out of the 48 points on the MOSCAD, they can use other inputs on the microwave system to add more capacity. Fiber carries data from microwave system to the NOC (where MOSCAD head-end is).

That prioritization means that DPS will likely supply a small RTU with at least one analog voltage input or D-Wire port for the propane sensor.

This agency's Fiscal Year runs July 1 - June 30 (this is very common). Fortunately, the telecom engineer I'm working with already has some money in current budget (at least $20,000 or so) to devote to this project. A large-scale roll-out would likely need to get approved by June 30, 2023 to be purchased after July 1, 2023.

As is common in government operations, he's "gotta spend budget money" or he will lose it. He does have an IT "counterpart" who will ask him tech questions at their next meeting. That drove a lot of his questions for me during my RTU and T/Mon explanations and demos.

They're changing their Eltek units out for Guardian units. They'll be able to add inverters so they can get rid of their large (about half a rack) Liebert 110 VAC UPS (end-of-life). At this point, that UPS is used only for interior lighting and other small things.

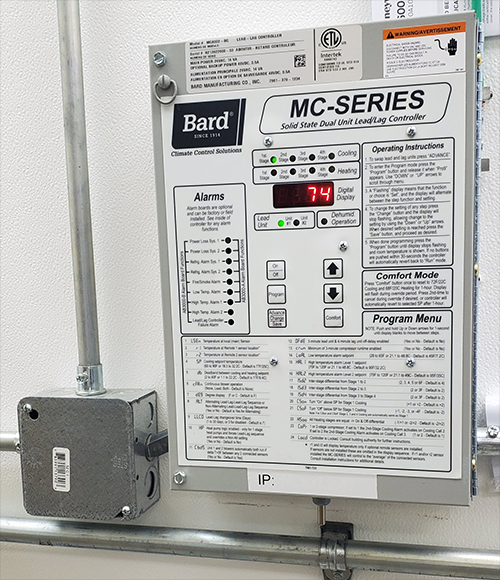

They're also replacing HVACs at their earliest sites. They are Bard 4000 series that have been installed since 2005. They have an in-house tower-light team, plus two generator technicians. I also mentioned our HVAC Controller as a possible all-in-one solution for sites. My client is potentially interested in that.

For this project, my client agreed to receive a pair of quotes that are each below $10,000 to make purchasing faster.

This will likely include a T/Mon MINI and a small handful of NetGuardian DIN RTUs or perhaps TempDefender G2 RTUs (Rack space is available, so DIN-mounting is not required). That creates an excellent small-scale system to evaluate the experience of using DPS equipment.

At DPS, we know that we need to provide a great experience with the first project. That directly affects our chances of earning your trust and expanding our relationship over the long term.

In this case, it's possible that we'll standardize on a larger RTU. A T/Mon LNX will eventually be required to handle 100+ remote sites.

If you're reading this, it's very likely that you've arrived on my website just like the client you've been reading about here. You're sifting through a lot of information, and it can be tough to know where to start.

Give me a quick call at 1-800-693-0351 or email me at sales@dpstele.com. We might even get to meet each other during an in-person site visit within a few weeks. That's truly the fastest way to get a project moving forward.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...