Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayChoosing a remote monitoring system is one of the most important, lasting choices you have to make for your organization.

Just like choosing a durable appliance (washing machine, refrigerator, etc.) for your home, this is something that you and your coworkers and going to have to depend on for 10 years or more.

If you make the best possible choice, you'll be happy for years. If you don't, you'll be cursing yourself as you make do with the lackluster monitoring system that consumed all of your budget dollars.

As always, a big choice like this one can have big career ramifications (positive or negative) for you.

You probably "wear a lot of hats" within your organization. Even if you don't, it's highly unlikely that you have much experience with RTUs, alarm masters, and sensors.

Evaluating remote monitoring systems just isn't something that any company has to do very often. They tend to last a long time. You've probably either never had to choose one or you did it a long time ago.

Fortunately, the process for choosing the right monitoring system is fairly simple. There are some finer points, but I'll give you a thorough introduction right now:

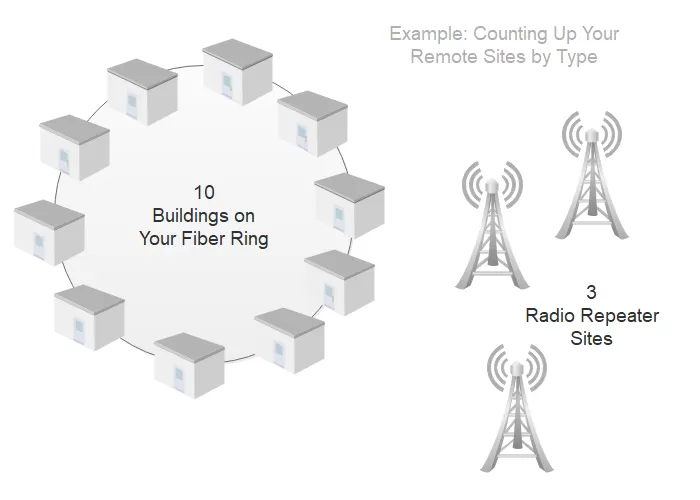

The first step in building a perfect-fit remote monitoring system for your network is to count up your remote sites.

Your remote sites are where all of the action is. You don't have anyone at these facilities most of the time.

Depending on your industry, you have radio towers on mountaintops, regional power substations, broadcast antennas, radio sites, and other mission-critical locations. These are the buildings, huts, and cabinets you need to monitor 7x24x365.

Get a simple count together.

It's helpful to sort your sites into groups (ex. "3 microwave repeaters, 10 fiber nodes...") because the next step is:

Now that you've counted up your remote sites, the next step is to size an RTU (which will be your central monitoring & control hub within the building) for each of them.

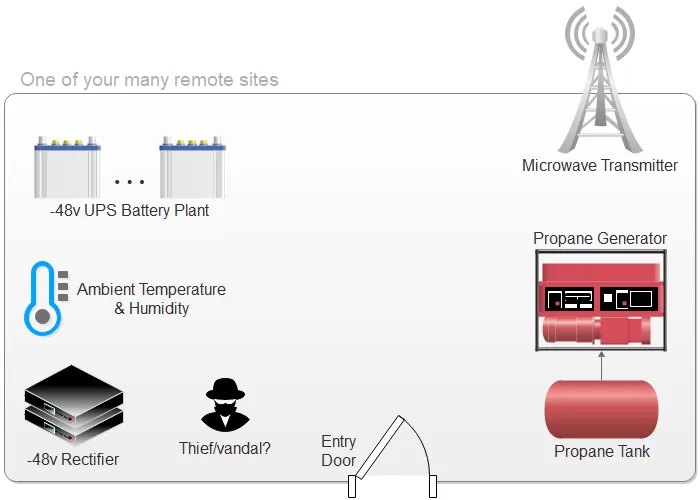

Start with one type of site (ex. "Microwave repeater sites"). What do you have there that you want to monitor?

Your list of things to monitor might look something like:

With your site-specific list of things to monitor, add up the number of discretes, analogs, & sensors that you'll need.

From the example list above, we'd have:

Finally, total up the I/O you tallied above. In our example, we need:

Your job now is to find an RTU that has the number of discretes & analogs you tallied (plus about 15% to allow for future growth), then the sensors you listed. You can duplicate the same RTU & sensors if you have other sites identical to this one.

Repeat this process for each different kind of remote site that you have.

Remember that it's a best practice to limit yourself to 2-3 different RTU models to facilitate sparing and training. It's good to custom-tailor things, but limited overkill is ultimately more efficient than absolute customization.

Your RTUs are your "boots on the ground" at each remote site. Now, you (possibly) need a master station to bring everything together.

First, let's establish whether you actually need a master station. At trade shows, I always tell my booth visitors that you can manage your RTUs directly if you have fewer than 10.

Most RTUs can send emails/SMS directly to you, and it's reasonable to manage them individually (via web interface) when you're still in single digits.

If that's you, congratulations! You don't have to worry about buying a master station right now. Any modern RTU you choose will have some kind of protocol output, so they'll work with a master station if you expand in the future.

If your network has 10 or more sites, you'll need some kind of master.

The standard in the industry is to price master stations by capacity. If you have 12 sites, for example, you might choose a master that supports up to 16 sites. If you have 50 sites, you might choose the next model up that can handle 64 sites.

Now that you have an idea of what monitoring system you need, give a few vendors a call to get price quotes.

Don't forget that vendors (at least the good ones) will offer some advice for adjusting your list. You should always make the final choice, but don't ignore advice that sounds right to you. Vendors specify monitoring systems all the time, even though you only have to do it once a decade.

Much like a car, total cost of ownership for your system goes way beyond the initial purchase price. Ask about the cost of recurring license fees, tech support, training, and maintenance.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...