Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayDuring a recent web demo, a client brought up the challenges they face with generator runtime reporting across their 40 locations. Their primary concern centered around meeting strict government regulations, particularly those enforced by an air quality control board that requires detailed logs of generator operations.

For this client, the stakes are high - failure to comply with these regulations could result in significant fines. To avoid this, the client needed a monitoring system that could not only capture accurate data but also easily integrate with their existing logs. Synchronizing the monitoring system's starting values with current generator logs is essential for ensuring compliance and accuracy.

The conversation highlighted a few key issues that some of our clients have faced, such as:

These challenges are common in many industries, and addressing them requires a tailored approach. Let's dive deeper into their conversation to see how a tailored solution was created.

The client's current setup only provides the client with a generic "generator fault" alarm. While this alert indicates an issue, it lacks the detail necessary for effective troubleshooting. The client explained that they have contact closures available for several critical parameters, including pressure, oil pressure, and antifreeze levels, among others. However, these parameters are not monitored individually; instead, they're lumped together under one broad fault alarm.

This setup presents significant risks. Without the ability to monitor each parameter individually, small issues can go unnoticed until they escalate into major problems. For example, a low oil pressure situation might trigger the same alarm as an antifreeze level issue. This leaves the maintenance team guessing which problem needs attention, delaying response times and increasing the risk of generator failures during critical moments.

Another crucial aspect of the client's monitoring needs involves tracking different types of generator runs - such as maintenance, routine exercises, and emergency operations. Differentiating between these run types is not just a matter of record-keeping; it's essential for accurate maintenance tracking and compliance reporting. Each type of run has different implications for the generator's wear and tear, fuel consumption, and overall health, making precise tracking more than necessary.

Our client's operations span a wide geographic area, with remote locations relying on varying power sources, including -48 VDC and AC power. Maintaining continuous monitoring across these diverse environments requires equipment that can handle these different power inputs smoothly.

The right solution will support a wide range of power inputs, making it an ideal solution for environments where power sources might vary or be inconsistent. This flexibility makes sure that monitoring remains uninterrupted, regardless of the local power infrastructure. Whether a site is powered by traditional AC or more specialized DC sources, the ideal RTU is able to adapt to maintain reliable operations.

Given the dispersed nature of the client's sites and the critical need for timely alerts, the ability to receive text message notifications directly from the monitoring system is a game-changer. Quick alerts are particularly important in situations where on-site personnel need to be notified immediately to prevent potential downtime or equipment failure.

The client emphasized the value of this feature, noting that timely alerts could significantly reduce response times and ensure that issues are addressed before they escalate. This capability enhances operational efficiency by enabling quick decision-making and reducing the time it takes to resolve critical issues.

With over 40 locations to manage, scalability is a key concern for the client. As their monitoring needs evolve, they require a system that can grow with them, allowing for the addition of new sensors and monitoring points without the need for a complete system overhaul.

Growth and expansion present numerous advantages for organizations. By scaling their monitoring system, clients can adapt to changing regulatory requirements and technological advancements, ensuring compliance and optimal performance.

The integration of new sensors and monitoring points can lead to improved data accuracy and richer insights, empowering decision-makers with timely information. This proactive approach not only enhances maintenance practices but also maximizes the lifespan of equipment, ultimately contributing to your cost savings and the return on investment (ROI).

Finding the best-fit solution is important for any organization because it directly impacts efficiency, compliance, and overall effectiveness. A tailored system that aligns with specific needs not only addresses existing challenges but also positions the company for future growth.

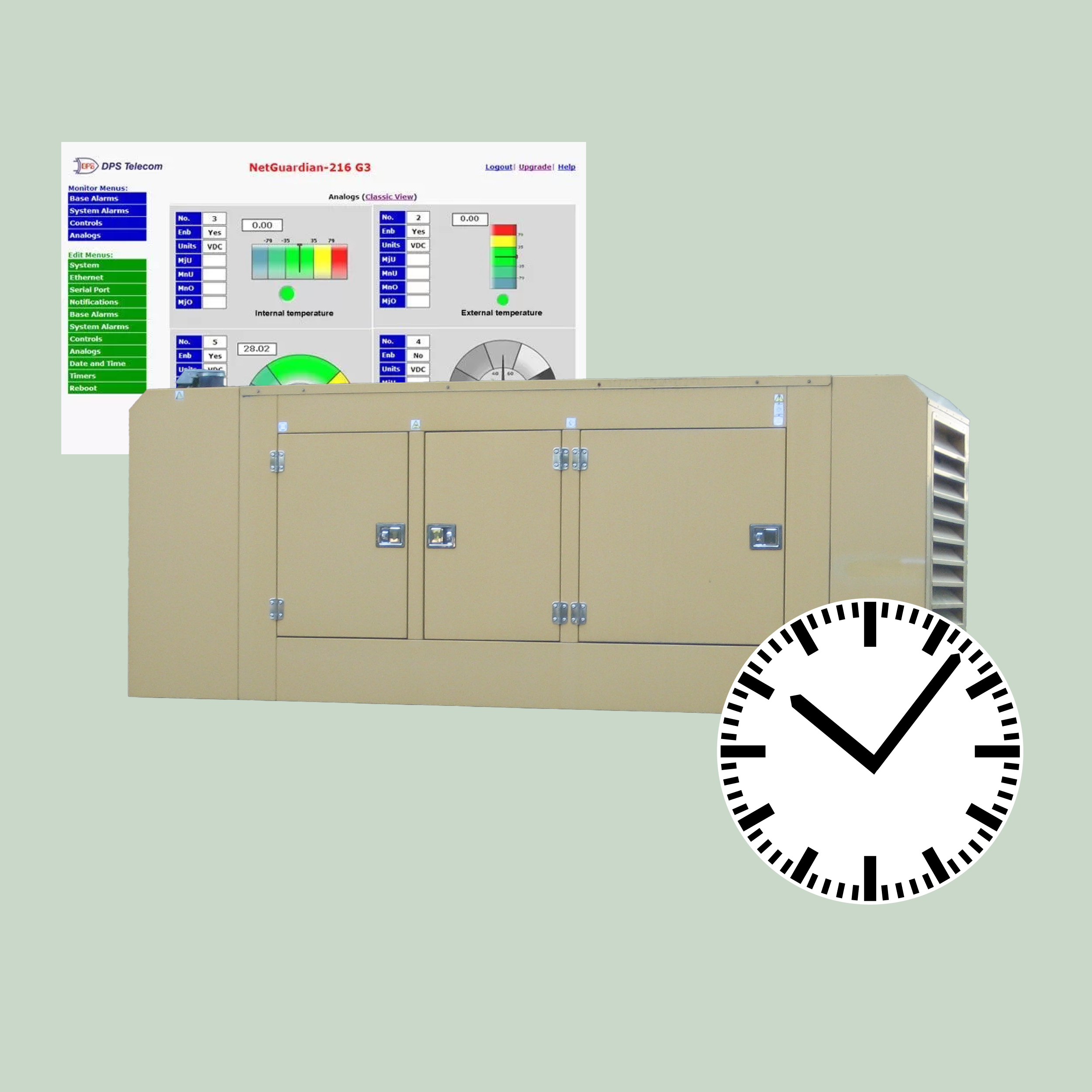

The NetGuardian G6 216 RTU offers a more granular approach to monitoring. Supporting up to 16 discrete alarms and six analog inputs, it allows for detailed monitoring of each critical parameter at these sites. By monitoring each aspect of the generator's performance separately, the client can uphold that maintenance schedules are strictly adhered to, significantly reducing the likelihood of generator failures when it matters most.

The NetGuardian 216 offers precisely the kind of scalability needed by this client. The device is designed to be modular, allowing for easy expansion as the client's needs change. Whether they need to add more monitoring points for new equipment or expand their environmental monitoring capabilities, the NetGuardian RTU can accommodate these changes without disrupting existing operations. This modularity future-proofs the client's investment, making sure it's capable of supporting their network's growth over time.

In addition to its scalability, the NetGuardian RTU features a secure web interface that allows for remote management and configuration. This capability is particularly valuable for a network as dispersed as the client's. It enables them to make adjustments from any location, enhancing both convenience and control.

This NetGuardian excels in generator tracking. It supports a wide range of power inputs, including both -48 VDC and AC adapters. This makes it an advantageous solution for environments where power sources might not be consistent.

The flexibility offered maintains uninterrupted monitoring, regardless of the local power infrastructure. This makes sure that critical data is never lost due to power inconsistencies.

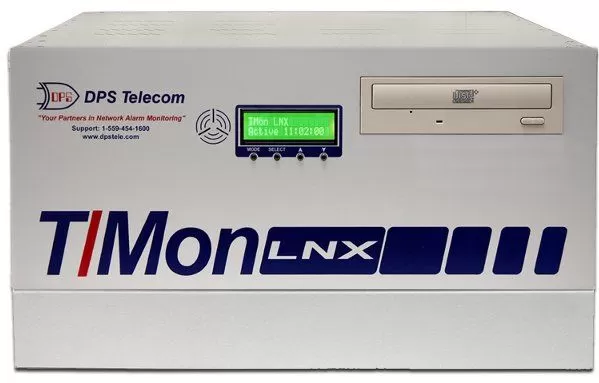

DPS Telecom's T/Mon master station also offers a strong solution to this challenge. By using derived alarms and timers, T/Mon can be customized to log each type of generator run accurately. This verifies that the client has a clear and detailed record of generator operations, which is vital for both maintenance planning and regulatory compliance.

With this system in place, the client can confidently report their generator usage to the air quality control board. The system provides peace of mind, allowing the client to know that all data is captured accurately and in the required format for audits and inspections.

The T/Mon system can also be configured to send customized alerts via SMS. These alerts guarantee that the right personnel are informed as soon as an alarm is triggered. The ability to respond to issues immediately adds to the peace of mind you'll have with this head-end device.

The client's need for a generator monitoring solution is driven by strict regulatory requirements and the critical nature of their operations. By implementing a customized monitoring system using DPS Telecom's NetGuardian RTUs and T/Mon platform, the client can achieve the detailed, reliable monitoring they require.

From capturing granular data on generator performance to ensuring compliance with government regulations, these systems provide the comprehensive monitoring needed to avoid costly fines and ensure smooth operations across all sites. The combination of flexibility, scalability, and real-time alerts positions the client to meet their current challenges while also preparing for future growth and regulatory demands.

If you're facing similar challenges in monitoring generator runtime and critical site parameters, DPS Telecom offers a range of solutions tailored to meet your specific needs. Our products provide the detailed, scalable, and reliable monitoring you need to stay compliant and keep your operations running smoothly.

Reach out to DPS Telecom today. Call 1-800-693-0351 or email us at sales@dpstele.com to discuss how we can support your monitoring requirements and help you avoid costly fines with accurate and tailored reporting solutions.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...