Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayBuying a remote monitoring device (an RTU or master station) is an expensive investment. Not only does it have an out-of-pocket cost, but device is also something you'll depend on. If you don't have visibility of vital gear at your remote sites, the cost of inefficiency, damages, and outages will quickly exceed any initial purchase price.

It's understandable and expected that you have questions and concerns. So would I.

Nobody wants to pay for a costly product that is missing critical details, lacks key features, has a complicated interface, or has questionable dependability.

You'll be off to a great start if you choose a monitoring manufacturer who listens to you and helps you choose the right gear.

With a client-first philosophy, your vendor will help you build a reliable monitoring system. Your long-term success (and deserved loyalty) will be the goal - not simple short-term sales.

You shouldn't be forced to buy anything more than what you need. You should have excellent options that fit your budget and don't consume any more dollars than necessary.

The initial step of your purchase experience should be a conversation between you and an applications engineer.

This expert has technical knowledge and is prepared to understand your monitoring needs. That's the first step in creating the right solution for you.

After listening what you have to say, your assigned applications engineer will conduct a "Needs Analysis". This is a detailed examination of all your network's sites and alarms.

Your current network monitoring system - if you have one already - is also an important factor. A good vendor will try to preserve your existing investment - even as it adds modern monitoring technology to improve your system.

After a detailed conversation with you (or probably several), your vendor should come up with a tailored monitoring plan based on your needs. If they have an existing solution that meets your requirements, then they'll send you a proposal describing the specific equipment and configuration that will get the job done.

If you want a more specific solution, your vendor's engineers should be more than happy to create a system suited to your network's individual needs.

Your network is complex and valuable. Don't accept anything less than the top-notch service described here. Even off-the-shelf components should be clearly shown in a custom diagram.

This helps you understand what's being proposed, proves your vendor is paying attention, and helps both of you notice and correct any foreseeable problems.

Good vendors also offer on-site turn-up assistance and training. It probably won't be free, but it should be reasonably priced and optional.

Full-service vendors recognize that excellent service helps everyone in the long run. A smoother installer and turn-up for you means less support required down the line and - in all likelihood - more purchasing and upgrades from you in the future.

Training and turn-up assistance services familiarize your personnel with all aspects of your new monitoring system.

Your vendor should aim to make the smallest possible impact on your activities and expenses, while still protecting your network with the highest level of remote-monitoring visibility.

Your monitoring equipment is your window to your network status. You can't afford to buy equipment that is untested and unreliable.

What good is quality customer service if a company doesn't provide you with a reliable device in the first place?

Your remote sites (at least some of them) are likely located in places that experience extreme weather conditions. Not only can extreme conditions force you to replace indispensable gear, they can also cost you windshield time.

For this reason, you need to be sure that your RTUs (deployed at remote sites that often involve harsh conditions) will be ready for any weather.

Your RTU vendor should subject all of their equipment to rigorous in-house compliance testing before shipping anything to you.

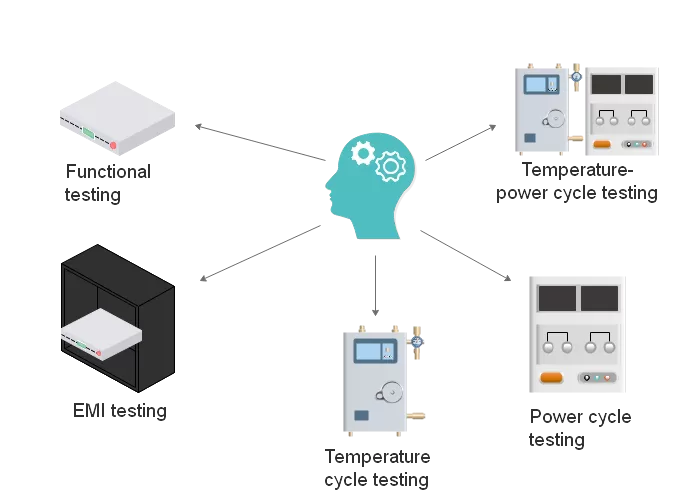

Good RTU testing should include:

Functional testing

Good monitoring equipment need to function properly. This test ensures that your device is doing exactly what it should do in the way that it should be done. These tests include making sure that analogs, alarms, controls, user menus, and firmware functions are running perfectly.

EMI testing

Electromagnetic Interference testing, also known as EMI testing, is one of the more advanced tests that RTUs can go through. If your equipment is vulnerable to EMI or emits excessive amounts, it may malfunction and even cause your other equipment to fail. EMI "surface area" is also a major contributor to power-surge damage.

Using an EMI test in a simple (but very expensive) anechoic chamber, you vendor can really dial in their RTU designs to dramatically reduce noise levels. EMI testing also allows self-certification with applicable NEBS standards (true NEBS certification involves a independent laboratory).

Temperature testing (hot & cold)

Your RTU must be subjected to the most extreme low and high temperatures to verify it will survive.

Every model that's tested should be put under the low end of its suggested functioning temperature range (ex. -40 F), reach that temperature, and be held there for several minutes.

The same thing is done for the high temperature range. The equipment, then, is cycled several times from hot to cold. The key is to make sure that your RTU not only can operate in those temperatures, but also can frequent changes (real-world seasons and day-night cycles are comparatively easy to withstand).

By performing this test, you vendor is able to design consistently reliable products that will not break down - even when your climate control fails or gets damaged. Your RTU should always be the last piece of gear at a site to fail.

Power-cycle testing

This is a simple test. Each unit is switched on and off for several hours to guarantee that it will remain working. This test will ensure that your unit won't stop functioning after only a few boot ups. It also emulates outages, which can happen during bad storms..

Power-cycling tests both hardware and software/firmware systems. The power supply must survive multiple hours of on/off torture testing. The firmware must boot up successfully after each and every power cycle.

Temperature-Power Cycle test

This is basically the previous two tests combined in one. The purpose is to put extreme stress on your gear to ensure maximum durability. To conduct this test, your vendor will subject the unit to either extreme heat or extreme cold and hold it there for many hours. The device is continuously power-cycled during this period.

It may seem like something "As Seen on TV", but a money-back guarantee is also very important when buying monitoring gear.

For a quality monitoring vendor/manufacturer, a money-back guarantee is a no-brainer. If they're making good equipment, they'll almost never see a return anyway.

A money-back guarantee is especially helpful when you're dealing with custom equipment. There are more variables in play with custom gear, so it's very reassuring to know that you can always return the solution if it doesn't do the job.

Look for at least 30 days to test new equipment at your sites, subjecting it to your specific real-world situations. If, at any time, during these 30 days, you decide that the equipment is not meeting your requirements for any reason, you can cancel your order. Simply return it for a full refund (which probably means you just tear up the vendor's invoice).

DPS Telecom is a manufacturer & direct seller of remote monitoring equipment. Headquartered in California, DPS designs and builds custom monitoring equipment for a global client base, including:

Telcos (Phone, Wireless, TV, ISP)

Utilities

Railroads

Police/fire/911

Government & Military

DPS provides all of the services, testing, and guarantees described here, making them a good manufacturer to consider for your project.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...