Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayWhen planning your SCADA system, the first step is to choose what kind of device will perform the monitoring of your industrial automation processes. For numerous reasons, this is a crucial decision, so it's important for you to research and go about it with your eyes open.

If you're reading this article, you're likely considering purchasing a PLC device for your monitoring system. Certainly, Programmable Logic Controllers may bring you several advantages, but before committing to anything, you need to know the downsides of these programmable logic units so you can make an informed decision.

Let's start by taking a look at some of the benefits PLCs have, then we can dive into their top three problems. Exploring these points and ranking them according to your unique scenario, you'll be able to make the best choice for your remote monitoring and control system.

PLCs, short for Programmable Logic Controllers, are small computers used for automating and controlling electro-mechanical processes. They're made with a lot of inputs and outputs in mind. They're built to handle vast temperatures, electrical noise, and vibration - things that are common in industrial processes.

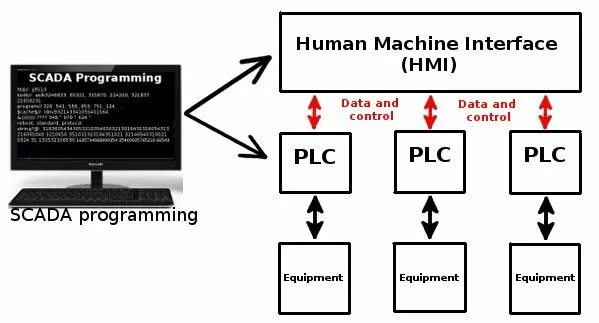

PLCs are a type of SCADA - Supervisory Control and Data Acquisition - device. They monitor, automate, and provide a human interface for the electronic control of processes. They take what would be a complicated mechanical process and provide the information and interface to make it an electronically monitored (& controlled) one.

In order to give you this high level of process control, a PLC will gather data through a series of discrete and analog sensors. Then, it'll either act on the data (in instances where it's been programmed to take action), or it will provide you with relevant information so you can take action. And because they're software-controlled, PLCs are adaptable and allow for fast, relatively low-cost reorder of processes.

Using PLCs to monitor your remote sites sounds like a good idea, right? It certainly can be, but it all depends on your unique scenario. This takes us below to the first downside that PLCs have:

PLCs are simple devices: usually a single sensor and a communications interface to output sensor data. They can also be highly customizable. Be careful, though, because they have a steep learning curve as they must be individually programmed in order to perform a task. Unless you have a PLC coder in your staff, you'll have to pay an outside expert to do this job (and teach them what you're trying to accomplish).

Whether you program your PLC yourself or hire another person to do the PLC programming for you, you'll have to endure a long wait before you're operational. It can take several weeks or months just to get everything coded and debugged.

So, since remote monitoring probably isn't your only job, you have to consider how much time you can devote to programming PLCs and if it's worth the effort. Usually, it isn't. If you need a solution with intelligence built-in that you can quickly get up and running, you should look for an RTU.

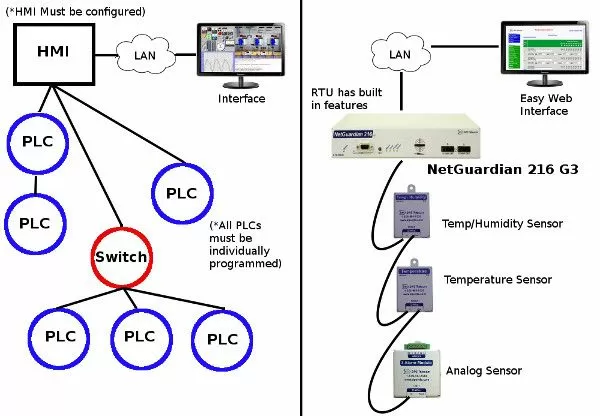

When you choose to use an RTU (Remote Telemetry/Terminal Unit), you can start installing it in the morning and be fully operational by the afternoon. RTUs are another type of device used for SCADA. They basically perform the same basic function of a PLC - remote alarm monitoring and control of remote equipment - but they go about doing this job differently.

Many advanced RTUs are simple to connect and some even offer plug n' play sensors. An easy-to-use graphical web interface makes it easy to set preferences and connect any other equipment you want to be monitored by the RTU.

The second disadvantage of a PLC is that, if you compare it to an RTU, you'll see big differences in size and capacity. An RTU usually has more inputs and outputs than a PLC. Typically, it also has more local processing power to work with collected data before it sends alerts to a central console (HMI) or directly to you (PLCs usually can't send direct-to-you messages at all, depending totally on the HMI).

Think about a single sensor and a communications interface to output data - the PLC - in contrast with an RTU that may have dozens of inputs and sometimes nearly as many relay outputs. The NetGuardian 832A, for example, has 32 discrete contact inputs, 8 analog inputs, and 8 relay outputs.

Differently from PLCs, RTUs tend to have more auxiliary capabilities as well. This is especially true at the upper end of the market. Still, using the NetGuardian 832A as an example, it has a built-in 10/100 switch, 8 serial ports for connecting other devices, and 2 backup reporting methods in addition to standard LAN. Its default operating temperature range is quite wide, and it can be extended with a build option that uses more rugged parts.

With PLCs, there is no programming standard, which leaves lots of room for programming error.

That's where we get into the third big disadvantage of using a PLC: while PLC manufacturers may offer tech support, it's costly and time consuming because they have to debug code that they didn't write. They simply don't know what your intent is.

With RTUs, though, since they come programmed by the manufacturer, the features are standardized. This makes it easy for their tech support to troubleshoot issues for you, saving you time and money.

Other sorts of post-sale services, such as training, turn-up assistance, and firmware updates will also be limited or non-existent, because of the individuality that each PLC has.

Can a PLC ever be the right choice? Yes! It all depends on your situation.

In certain scenarios where you have a lot of processes happening in one space, like in a manufacturing facility, PLCs can work. Since such a facility will also have environmental controls, you don't necessarily need the wide temperature range and rugged build quality you'd get with a good RTU. The fact that PLCs have only a few inputs makes them a more liquid resource.

You can move PLCs as needed, and ordering additional/different PLC models that will most likely be less expensive than RTUs. So, if most of your locations only require just a few monitor/control nodes, PLCs might be the best choice for you.

An RTU, when compared to a PLC, is usually more rugged and has higher monitoring and control capabilities than a PLC. So, because of that, SCADA RTUs are superior at locations where many items must be monitored and controlled.

RTUs have their place protecting the IT assets of a facility. In the server room of a manufacturing facility, for example, the monitoring and control needs are exactly the same as those in the server room of a major office building. RTUs are better suited for this kind of environment.

If you have any gear at a location, it should have automated monitoring. Even if the location is staffed, many problems don't make an obvious noise or emit a visual cue like smoke until it's too late. Using RTUs will be more cost-effective in the medium/long run once you'll be able to monitor multiple things with just one power supply, one chassis, etc.

Also, your gear won't be moving very often, so a single deployment should meet your needs for years - just make sure to have enough room left over on your RTU to allow for expansion, or check beforehand with your manufacturer to see if they offer expansion chassis, such as the NetGuardian DX.

Another point to keep in mind is that, even though PLC customization offers advantages for experienced users, others may prefer to order an RTU that is already custom-designed for their monitoring and control situation.

The real trick here is finding a manufacturer with the necessary facilities and experience to help you. Look for a vendor that has engineering and manufacturing inside of its own organization - a full-service company. The last thing you want to do in the deployment of your vital SCADA system is to wait for overseas development and manufacturing to be delivered.

As long as you watch for this potential deal-breaker, you'll have a great experience requesting a custom-designed RTU for your SCADA system. If you do your homework, this won't be more expensive than purchasing an off-the-shelf product. If you order a reasonable quantity (at least 10 or so), it's generally worthwhile for a manufacturer to develop a solution for you.

Wait time will usually be fairly short - about 1 to 2 months from a company that has its own engineering and manufacturing. Also, remember that, while your custom RTU may have unique capabilities, there probably isn't anything out of this world in terms of its functionality. It shouldn't require nearly the development time that a completely new product would.

Did you reach the conclusion that going with RTUs will be a better choice for your scenario? Are you wondering what your next step should be now? If so, we (DPS Telecom) are here to help you.

When you contact our sales team, we can set a time for a detailed personalized consultation. Our immediate goal is to determine your real needs, both for the present and the future. Then we'll design an alarm monitoring application that will serve as a bridge between your current state and future objective. Our intent here is to create a solution that will be customized for your unique scenario.

In most cases, our clients' needs can be met with an existing DPS product. However, if current products don't provide you the perfect-fit solution, our engineering team will be more than happy to develop a custom solution that will meet your exact requirements. We can modify our hardware and software so they can fit your needs.

Our hardware is modular and the intelligence is built into the software, so we can tweak it pretty easy until it's the absolute best fit for you. (Of course, if it turns out that a PLC is a superior choice, we'll tell you that honestly rather than upset you down the road)

We guarantee that your alarm monitoring solution will work as we promised, and if it doesn't, you're not on the hook for anything. After your system is installed, you can try it for 30 days, and if you're not happy about it for any reason, you can send it back, paying nothing for the equipment, for the training, for the initial shipping costs. Just ship it back to DPS for a full refund. That's our 30-day, no risk, 100% money-back guarantee.

Also, keep in mind that you won't be on your own after your purchase. We'll continue to support you with installation services, training, and 24/7 free tech support (we're REALLY motivated to keep you from wanting a refund, obviously!).

Are you ready to take the next step to better visibility of the network at your remote sites? Or simply want more information about remote alarm monitoring? You can contact me and I'll be happy to help you make an informed decision to get you that perfect-fit device for your unique remote monitoring needs.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...