Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayIf you're working on the development of gear network monitoring systems, you've likely heard about Programmable Logic Controllers (PLCs), Remote Telemetry/Terminal Units (RTUs), and/or Power Distribution Unit (PDU). Generally used for supervisory control and data acquisition (SCADA), many people assume to know their differences. However, do you know the actual distinctions between a PDU, RTU and a PLC, and is there an advantage to using one over another?

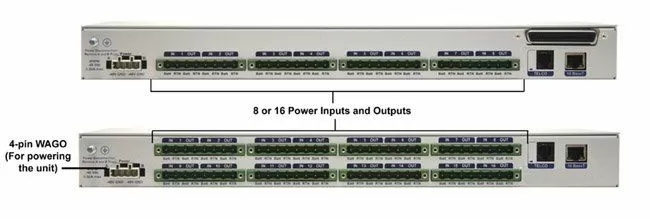

A Power Distribution Unit, or simply PDU, is similar in function to a high-tech power strip: it allows the main power system to be divided up to the many different pieces of equipment on site.

A key feature of these units is the ability to remote "cycle" the power on and off to a device plugged into it. The ability to remotely control this "on/off" functionality is a valuable feature, especially if the device is physically far away. These units also include a fuse panel, making the purchase of a separate fuse panel unnecessary.

Rack mount unit PDUs are generally used in server rooms, data centers, remote telecom sites, and any other situation or location where gear needs on off toggling, and remote rebooting. The inclusion of a remote rack PDU allows remote locations to become entirely self-sustaining, eliminating the need for on-site personnel.

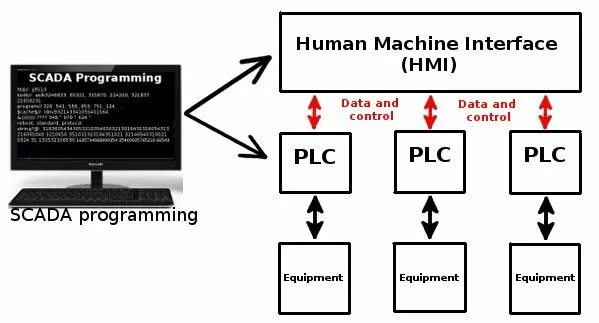

A PLC is a specialized computer used for partially automating and providing electronic control of electromechanical processes. They're designed with multiple inputs and output arrangements in mind, and typically built to handle extreme temperatures, electrical noise, and vibrations often encountered in industrial processes.

In other words, PLCs are a type of SCADA device - they monitor, automate, and provide a human interface for electronic control of processes. They take what would otherwise be a complicated mechanical process, and digitize it by providing relevant information as well as an intuitive interface.

To provide this sophisticated level of process control, a PLC gathers data through a series of discrete and analog sensors. It then either acts on the data in instances where it's been programmed to take action or provides its user with relevant data so he or she can take action. Also, since they're software-controlled, PLCs are supremely adaptable and allow for fast, relatively low-cost reconfiguration of processes.

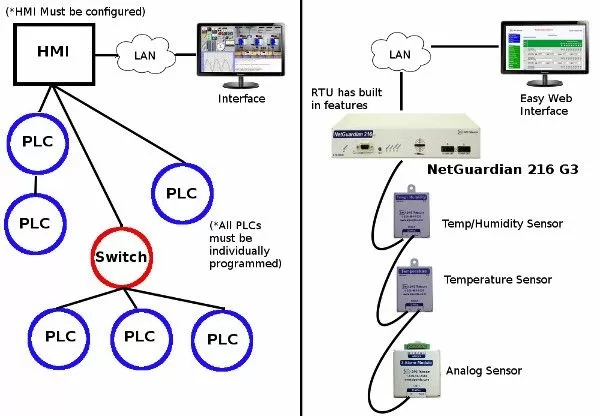

Finally, an RTU is an industrial computer that actually monitors and reports alarms from equipment in your racks. This allows you, the network operator, to manage your network more effectively, keeping service flowing to your customers/users and protecting your revenue stream.

Some RTUs are capable of remote controlling remote site gear using control relay contacts or protocol-based commands. Without this ability, an RTU can only report remote events to you. While this is valuable, you still must physically travel to the monitored location if a change must be made. An RTU that includes remote control capability reduces this windshield time to a simple mouse click (or even a fully automated response).

In summation, an RTU is a device that gives you visibility over remote sites vital to your business operations. RTUs are a proven, low-cost solution for monitoring, optimized for network, communications, and transportation processes. They provide critical alarm notifications for technicians, allowing them to take action and minimize interruptions and serious issues.

PLCs provide high-level algorithmic control for automation. However, they're not scalable, nor do they provide a large number of sensors for information reporting.

Even though RTUs are PLC-like devices, they're equipped with a larger number of discrete and analog sensors. In addition, they monitor processes and use control relays to execute basic controls.

Secondly, PLCs often operate in proprietary protocols, many of which are not compatible across platforms.

RTUs are more flexible and intuitive, often possessing a graphical interface standardized with via SNMP. RTUs also report monitoring information from legacy or proprietary devices, so long as they output ASCII.

In general, companies are opting for RTUs over PLCs because of their flexibility and scalability. RTUs, like The NetGuardian, can output plain-text alerts. They can report the status of controlled processes remotely, sending alerts to technicians' emails or cell phones.

Some other primary differences between RTUs and PLCs are:

Deployment time

RTUs allow you to start the installation in the morning and be fully operational by the afternoon. Many advanced RTUs are simple to connect and some even offer plug 'n' play sensors. An easy-to-use graphical interface web interface allows one to quickly set preferences and connect any other equipment you want to monitor.

Even though PLCs are simple devices, they can also be highly customizable. Generally, they have a steep learning curve and must be individually programmed in order to perform general tasks. Unless you have a resident PLC coder in your company, you will have to pay an outside expert to code your operations, likely at a premium.

Whether you program your PLCs in-house or hire an expert to do it for you, you'll be looking at a long wait before you're operational; often upwards of several months.

Scalability

RTUs are scalable and grow with your network. With flexible DNP3 or Modbus RTUs, you can always integrate with SCADA in the future as your network evolves. There is often little to no compromise.

PLCs, are less scalable, have less capacity and must be manually configured and programmed.

RTUs with defined functions almost always have faster tech support for less or even zero cost.

With PLCs, there is no programming standard, leaving a high chance of both ambiguity and error. While PLC manufacturers may offer tech support, it's costly and time-consuming when they need to refactor or debug code they did not implement. In addition, they may not know your intent and may leave out important functionality.

Since RTUs are pre-programmed by the manufacturer, the features have been standardized; making it easy for tech support to troubleshoot your device, ultimately saving you time and money.

The most important aspect that differentiates a PDU from an RTU or from a PLC is the ability to monitor several other things at your remote sites.

PDUs and RTUs have alarm monitoring abilities, which means that these devices allow you to monitor discrete and analog alarm data from your important gear. PDU functionality, however, allows you to control power consumption - and nothing else.

If you've had to jump in your truck and drive hours to a site to reboot jammed equipment, you already know exactly why you need a PDU. With a power switch, you'll be able to power on/off and reboot all your critical devices - right from your desk at the office.

Just make sure, though, that you won't need to monitor anything else in your remote sites in the future. If you're not sure, it's always a safe bet to invest on a PDU that also has alarm monitoring capabilities, such as the Remote Power Switch.

What about a PLC? Is it ever the right choice? In certain situations where you have a lot of processes happening in one space, i.e. in manufacturing, PLCs can work.

Since these kinds of facilities also have environmental controls, you don't necessarily need a wide range of temperature and humidity levels, as well as the rugged build quality you'd receive with a good RTU. The fact that PLCs have few inputs makes them more flexible. You can move PLCs as needed, and ordering additional/different PLC models is generally less expensive.

In most environments, however, an RTU is superior. If you have gear at a remote site, it makes sense to have automated monitoring. Even when the location is staffed, many issues have poor visibility and are only obvious when serious problems occur.

Using RTUs will be more cost-effective in the long run, allowing you to scale effortlessly while monitoring dozens of devices with a single power supply, chassis, etc.

And since your gear won't be moving very often, a single deployment should meet your needs for years just make sure to have enough room left over on your RTU to allow for expansion, or make sure your manufacturer offers expansion chassis, such as the NetGuardian DX.

Deciding whether you need an RTU, PLC or PDU is an important decision. After all, it will affect the health of your revenue-generating equipment.

But you don't have to go through this alone. We are here to help you.

We perform detailed consultations that assess your true needs, which involves looking at the challenges you're experiencing right now, an extensive site survey, and evaluating where you want to be in the future. The main goal of our personalized consultation with you is to find out what a perfect long-term system would look like for your specific scenario.

There are no strings attached. Just give us a call today and we can get your remote monitoring system project started.

Morgana Siggins

Morgana Siggins is a marketing writer, content creator, and documentation specialist at DPS Telecom. She has created over 200 blog articles and videos sharing her years of experience in the remote monitoring industry.